Suction cup cover plate with stainless steel insulating strip

An insulating strip, stainless steel technology, applied in the direction of using tools for cleaning, load hanging components, cleaning methods and utensils, etc., can solve the problems of reducing the service life of suction cups, insulation layer damage, etc., to reduce damage, set stability, strengthen The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

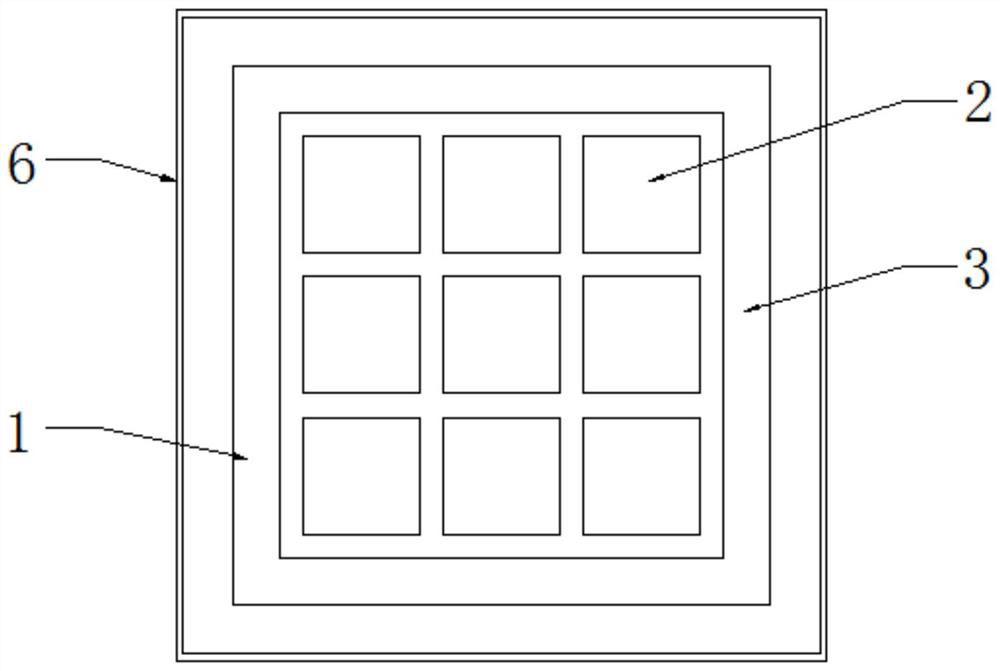

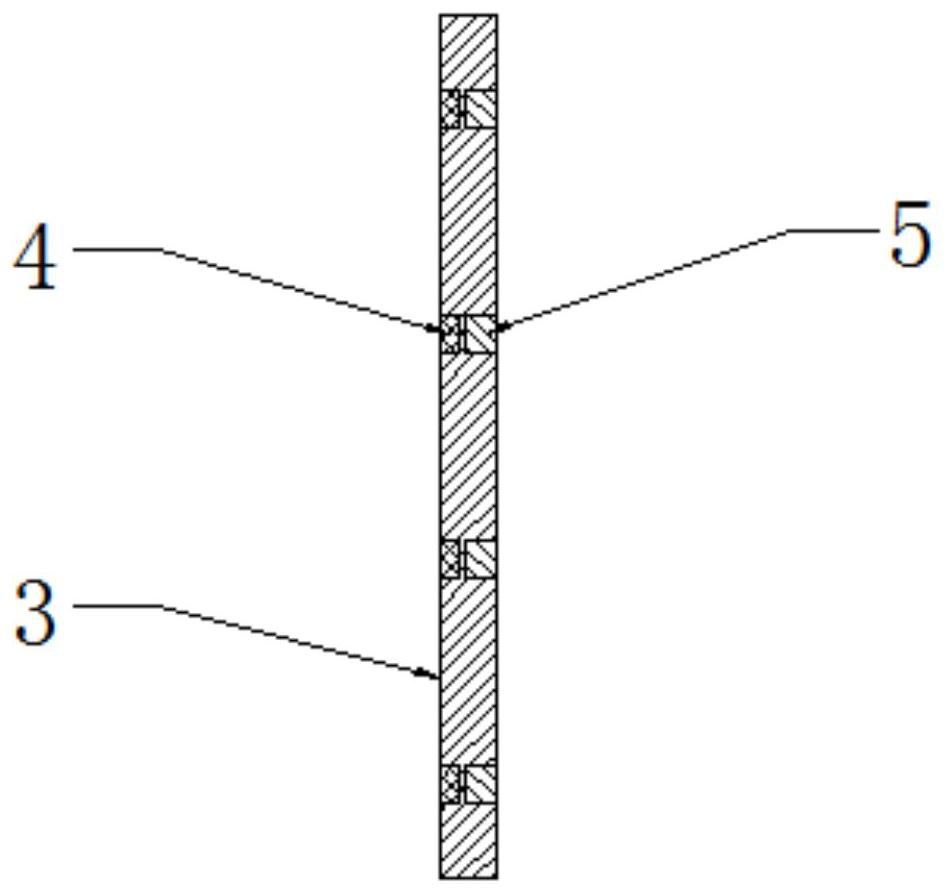

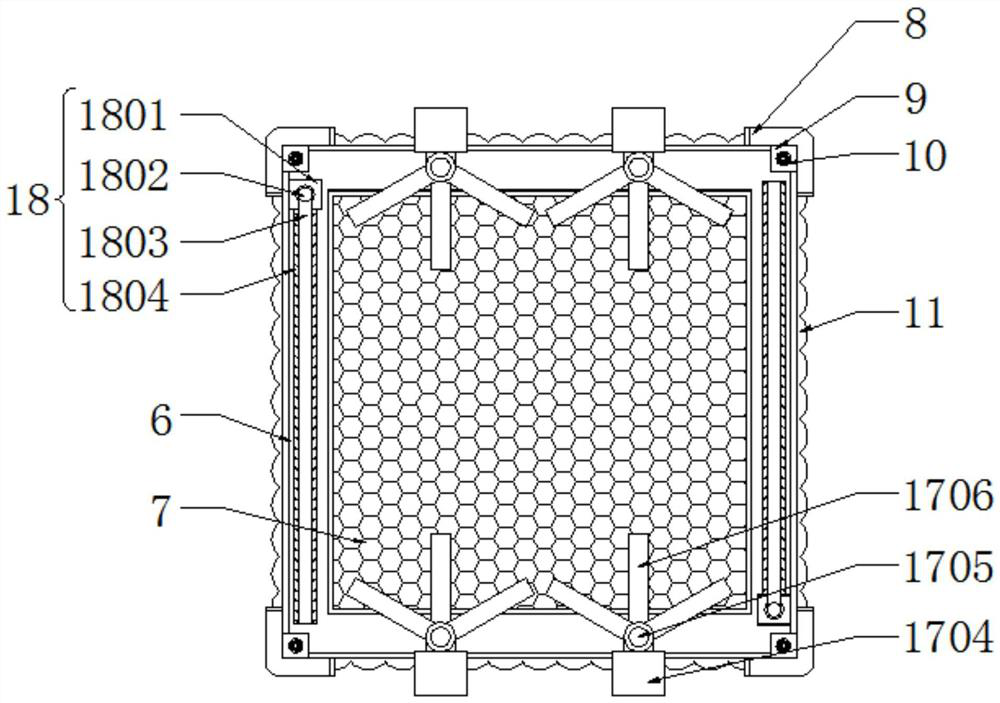

[0027] see Figure 1 to Figure 2 , the present invention provides a technical solution: a suction cup cover plate provided with a stainless steel insulating strip, comprising a suction cup cover plate 1, an insulating epoxy strip 4 and a stainless steel insulating strip 5, a pole piece 2 is fixed in the middle of the suction cup cover plate 1, and The outer side of the pole piece 2 is provided with an insulating groove 3, the insulating epoxy strip 4 is embedded in the interior of the insulating groove 3, the stainless steel insulating strip 5 is embedded in the inner front of the insulating groove 3, and the stainless steel insulating strip 5 is located on the insulating epoxy strip. 4 on one side.

[0028] Such as Figure 1-2 As shown, the suction cup cover plate 1 has a rectangular structure, and the symmetrical center of the suction cup cover plate 1 coincides with the symmetrical center of the insulating groove 3; nine pole pieces 2 are arranged symmetrically with respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com