Spoon transferring device

A transfer device and spoon technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of affecting packaging, slow manual transfer, and increase of waste products, so as to achieve uniform and neat slitting, make full use of time, and improve The effect of production beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

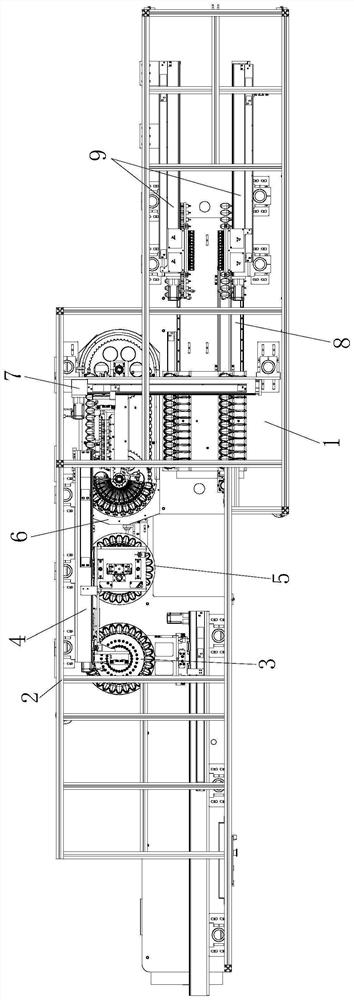

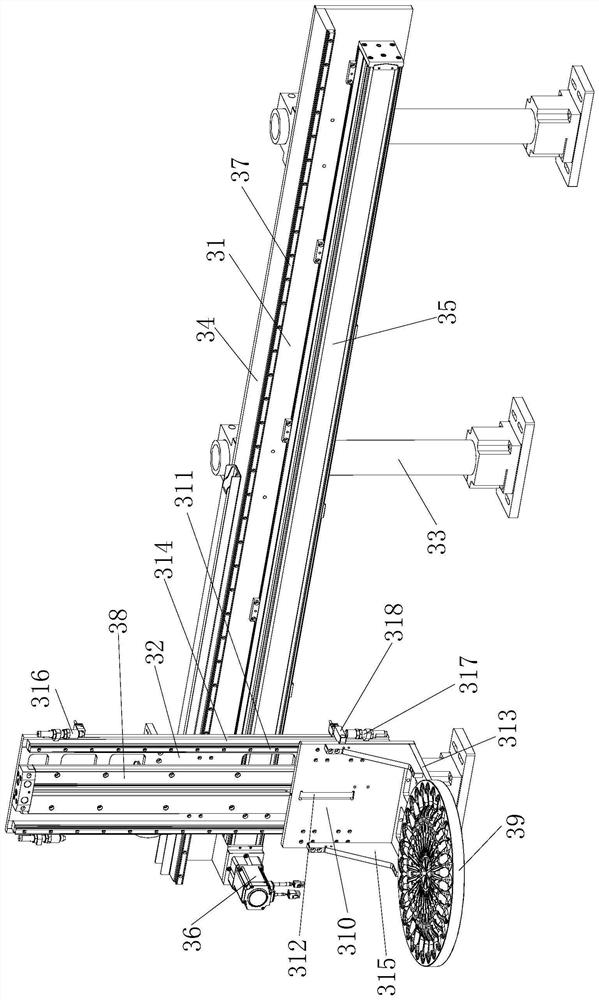

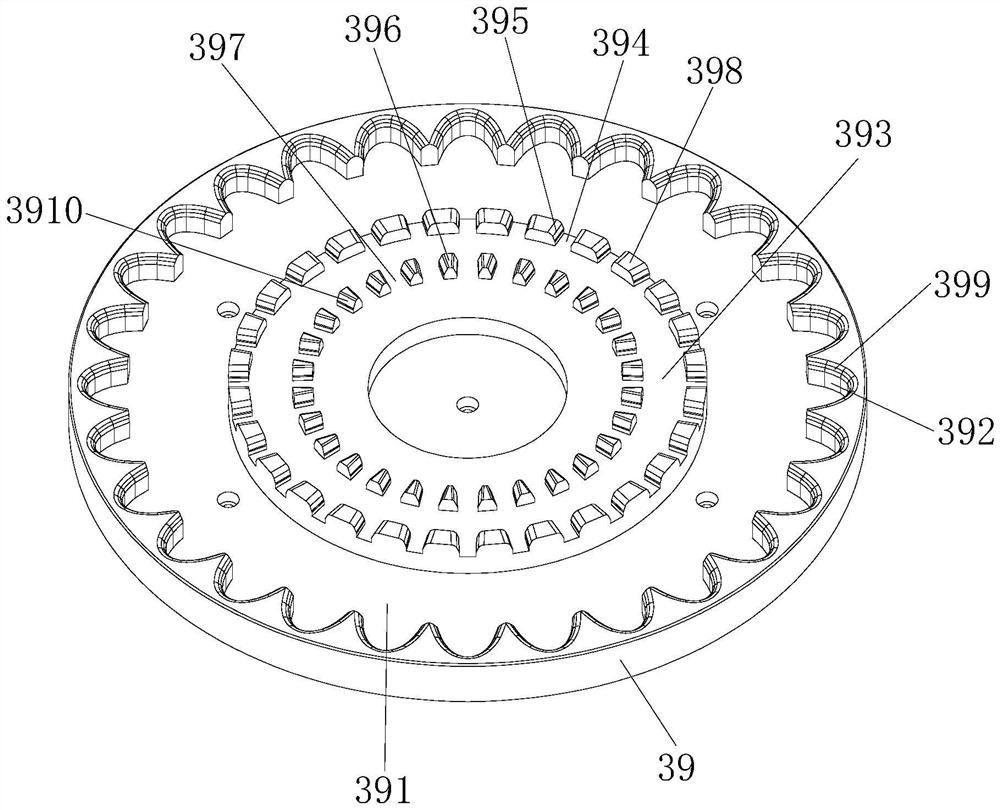

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1-20 As shown, the spoon transfer device includes a receiving moving mechanism 3, a material moving mechanism 4, a turntable mechanism 5, a transfer mechanism 6, a feeding mechanism 7, a finished product moving mechanism 8, and a finished product unloading mechanism 9 located above the rack platform 1. A protective cover 2 is also installed on the rack platform 1 . The injection molded spoon assembly includes several spoons arranged around and a sprue ring located in the middle of each spoon and connected to the handle of each spoon. The number of spoons in the spoon assembly matched with the present invention is 28.

[0038] Among the above-mentioned technical schemes: figure 1 , 2, 3, the receiving moving mechanism 3 is responsible for moving the injection molded spoon assembly of the injection molding machine. The material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com