Bolt-nut assembly fastening tool

A technology for fastening tools and nuts, applied in the direction of motor tools, manufacturing tools, screwdrivers, etc., which can solve problems such as difficult operation, reduced interchangeability, and increased cost of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

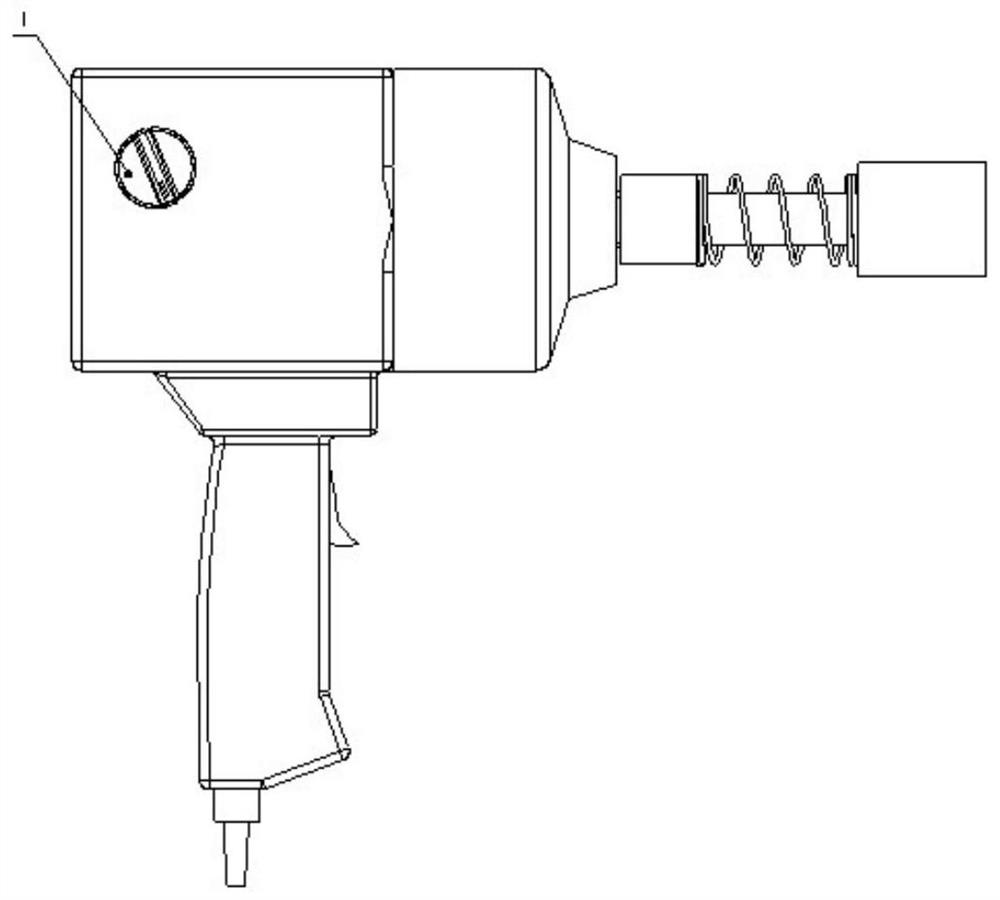

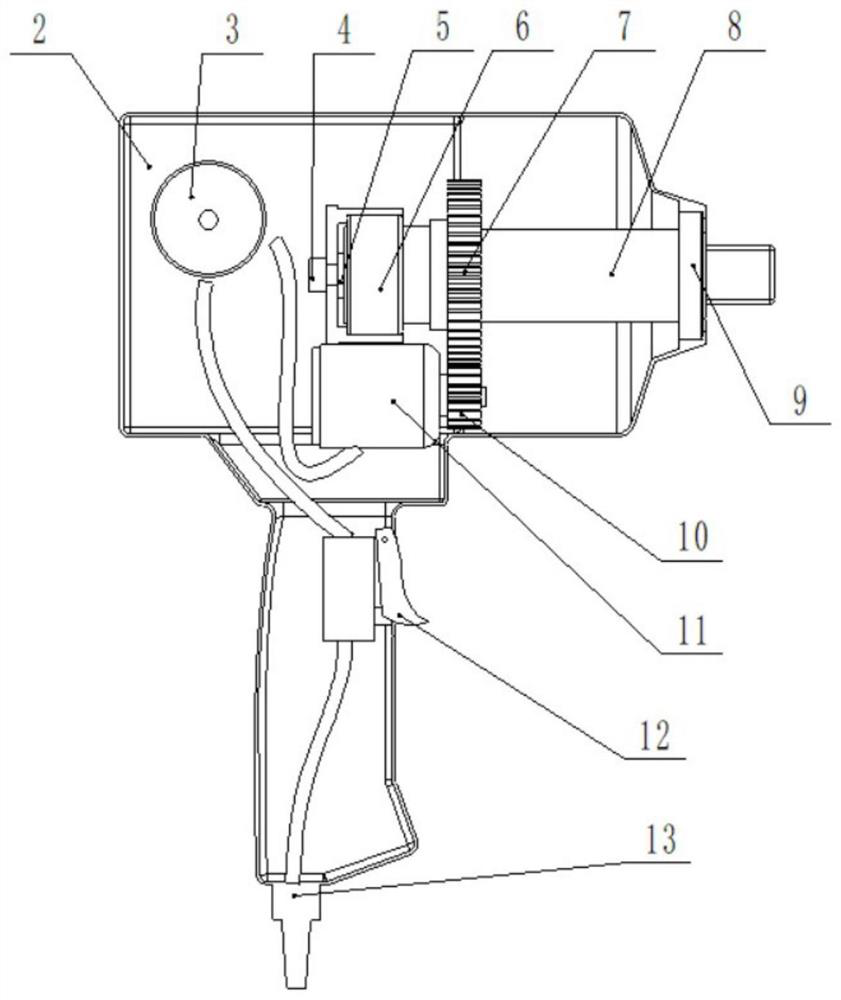

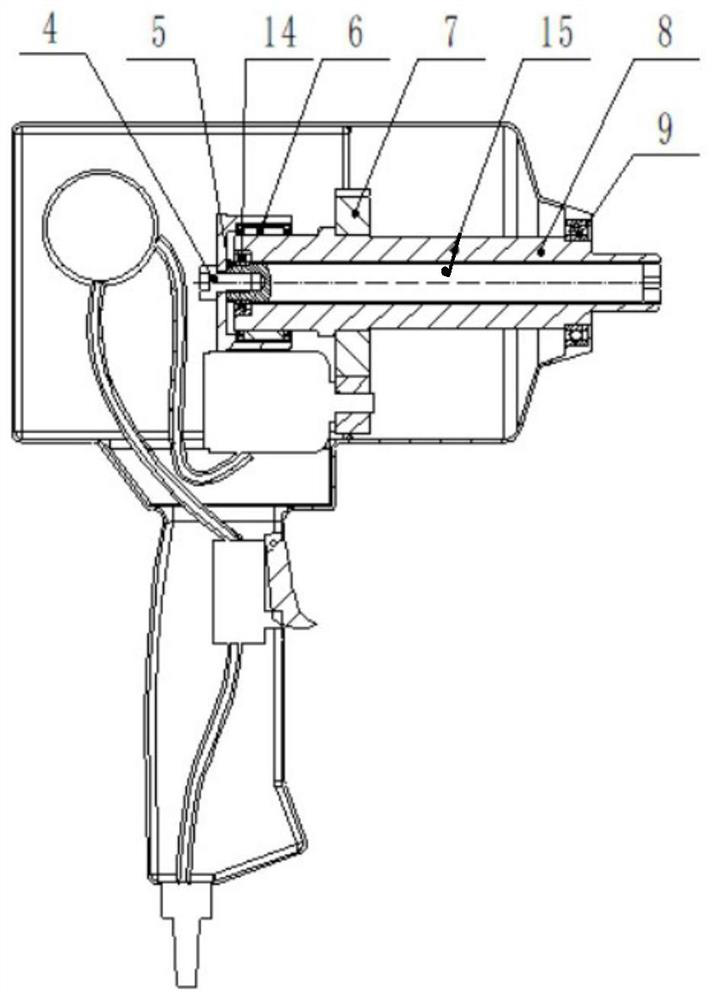

[0021] 1. A bolt-nut assembly tightening tool, as shown in the figure, is divided into two parts: a hollow square head air trigger and a nut-specific sleeve.

[0022] 2. The hollow square head air trigger of the bolt-nut assembly fastening tool is composed of a torque adjustment knob 1, an air trigger housing 2, a speed regulating and torque device 3, a fixing screw 4, a bearing retaining ring 5, and a sealed needle roller bearing with a cover 6. Large gear shaft 7, hollow shaft 8, sealed ball shaft with cover 9, pinion gear 10, air motor 11, trigger 12, gas line joint 13, sealed ball bearing with cover 14, central shaft 15 and necessary gas lines . The air trigger is connected with the surrounding compressed air pipeline through the tail air line connector 13 to provide a power source for the air motor 11 . The gas trigger housing 2 is divided into front and rear ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com