Mechanical stamping die facilitating discharging

A technology of mechanical stamping and mould, which is applied in the direction of manufacturing tools, metal processing equipment, stripping devices, etc., and can solve the problem of inconvenient waste discharge from moulds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

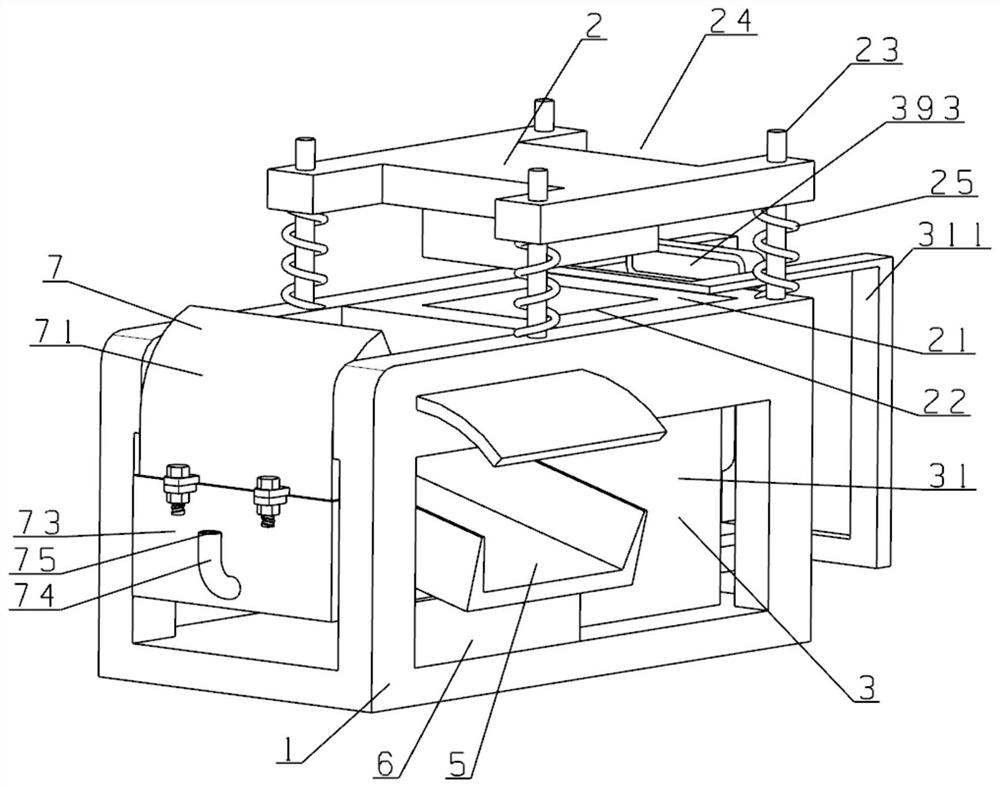

[0025] In one example, see Figure 1~Figure 5 , a mechanical stamping die for convenient discharge, including a support frame 1, and also includes:

[0026] Mold structure 2, the mold structure 2 includes a fixed mold 21 fixedly connected with the support frame 1, the middle part of the fixed mold 21 is provided with a punching hole 22, and one side of the support frame 1 is fixedly installed with multiple groups of guide rods 23, so The guide rod 23 is slidingly connected with a movable mold 24, and the movable mold 24 is connected with the support frame 1 by a first spring 25;

[0027] Discharging device 3, described discharging device 3 comprises the main frame 31 that is fixedly installed on support frame 1 side, and described main frame 31 is connected with carrier frame 33 by second spring 32, and described carrier frame 33 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com