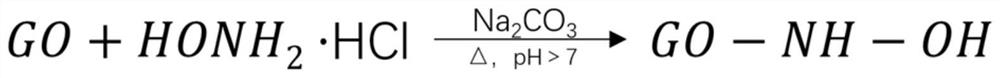

Preparation method of hydroxylamine functionalized graphene membrane and application of hydroxylamine functionalized graphene membrane in gas-water separation

A technology of graphene film and graphene, which is applied in the field of preparation of hydroxylamine-functionalized graphene film, can solve the problems of slow water separation, achieve good air tightness, simple preparation method, and broaden the application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add graphene oxide (100mg) and hydroxylamine chloride (350mg) into water, adjust pH = 10, react at 70°C for 12 hours, transfer the reaction product to a suction filtration device, and use a microporous filter with a pore size of 0.22μm Membrane suction filtration makes the hydroxylamine functionalized graphene film-forming. Wash the filter membrane with water (20 mL×10) and absolute ethanol (5 mL×3). After drying and weighing, the loading capacity of functionalized graphene is 55.1 g / ㎡, and the water flux is 3658.2 L / ㎡ / h. The above-mentioned graphene oxide needs to be pretreated as follows before use: vacuum drying (60 °C, air pressure less than 5 kPa) for more than 2 hours.

[0029] Among them, the calculation method of the loading capacity is: the weight of the functionalized graphene divided by the cross-sectional area of the water; the weight can be obtained by weighing, and the cross-sectional area is 0.00159㎡ (R=45 mm);

[0030] Water flux test method: after t...

Embodiment 2

[0035] Add graphene oxide (100mg) and hydroxylamine chloride (220mg) into water, adjust pH=10, react at 70°C for 12 hours, transfer the product to a suction filtration device, and use a microporous filter membrane with a pore size of 0.22μm Suction filtration to form a film of hydroxylamine functionalized graphene. Wash the filter membrane with water (20 mL×10) and absolute ethanol (5 mL×3). After drying and weighing, the loading capacity of the functionalized graphene obtained was 55.6g / ㎡. The tested water flux is 3674.4L / ㎡ / h. Test method is the same as embodiment 1.

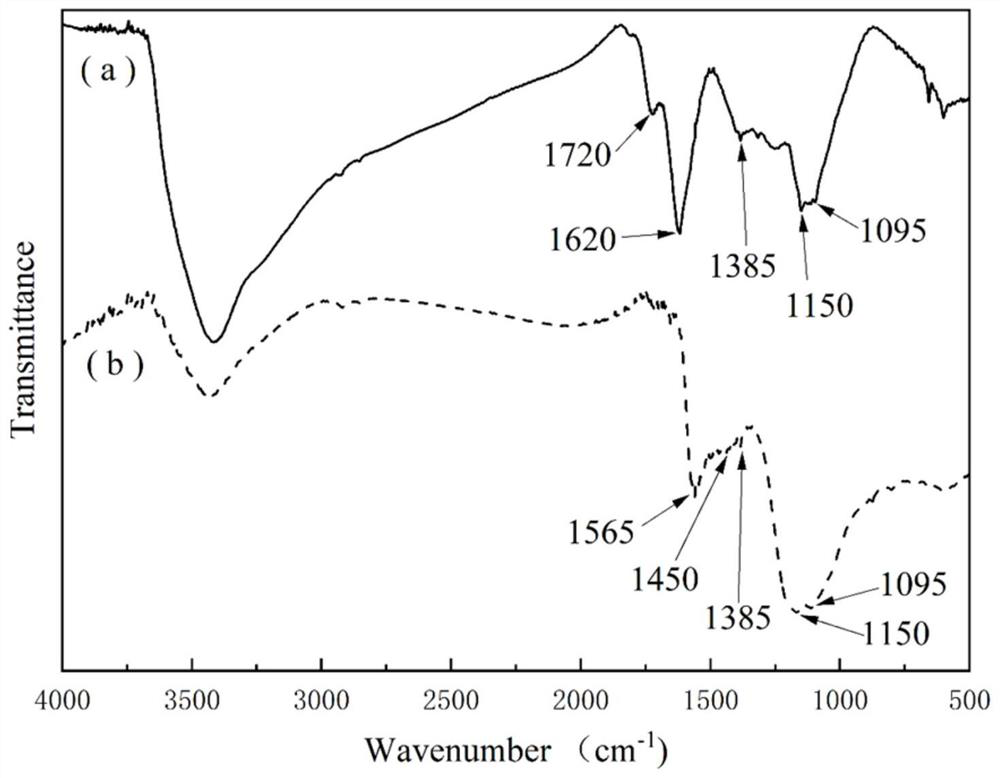

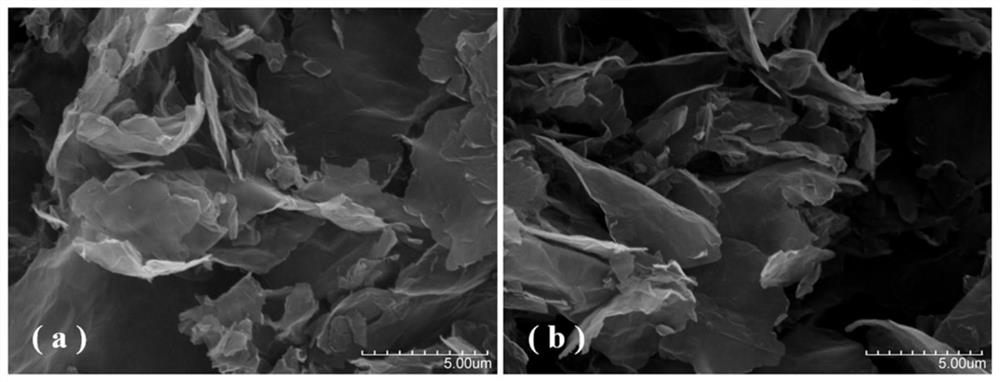

[0036] Infrared spectra of functionalized graphene and figure 2 Consistent, the scanning electron microscopy images of functionalized graphene and the scanning electron microscopy images of the filter membrane were compared with image 3 , Figure 4 Consistent, the water permeability and gas barrier properties of the membrane meet the Figure 7 description of.

Embodiment 3

[0038]Add graphene oxide (200mg) and hydroxylamine chloride (100mg) into water, adjust pH=10, react at 70°C for 12 hours, transfer the product to a suction filtration device, and use a microporous membrane with a pore size of 0.22μm Suction filtration to form a film of hydroxylamine functionalized graphene. Wash the filter membrane with water (20 mL×10) and absolute ethanol (5 mL×3). After drying and weighing, the loading capacity of the functionalized graphene obtained was 53.3 g / ㎡. The tested water flux is 3809.9L / ㎡ / h. Test method is the same as embodiment 1.

[0039] Infrared spectra of functionalized graphene and figure 2 Consistent, the scanning electron microscopy images of functionalized graphene and the scanning electron microscopy images of the filter membrane were compared with image 3 , Figure 4 Consistent, the water permeability and gas barrier properties of the membrane meet the Figure 7 description of.

[0040] By embodiment 1-3, within the range descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com