Straw cutting equipment for livestock feed processing

A cutting equipment and feed processing technology, applied in cutting equipment, application, grain processing and other directions, can solve the problems of reducing the uniformity of straw, inconvenient straw cutting, etc., and achieve the effect of improving uniformity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

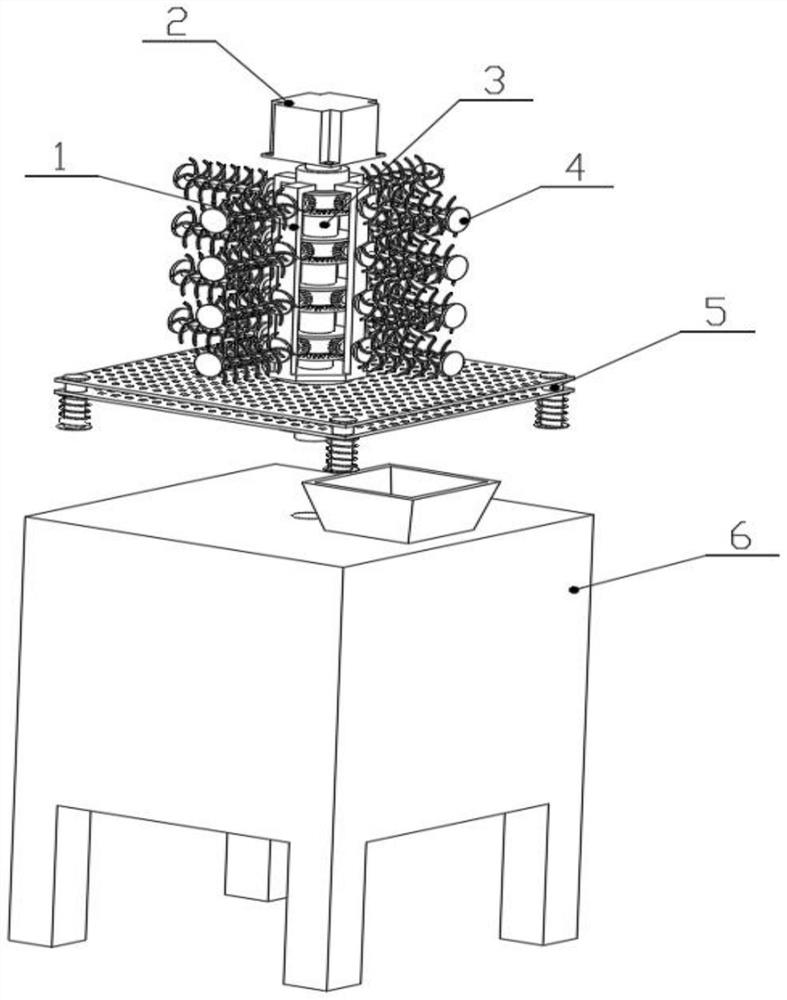

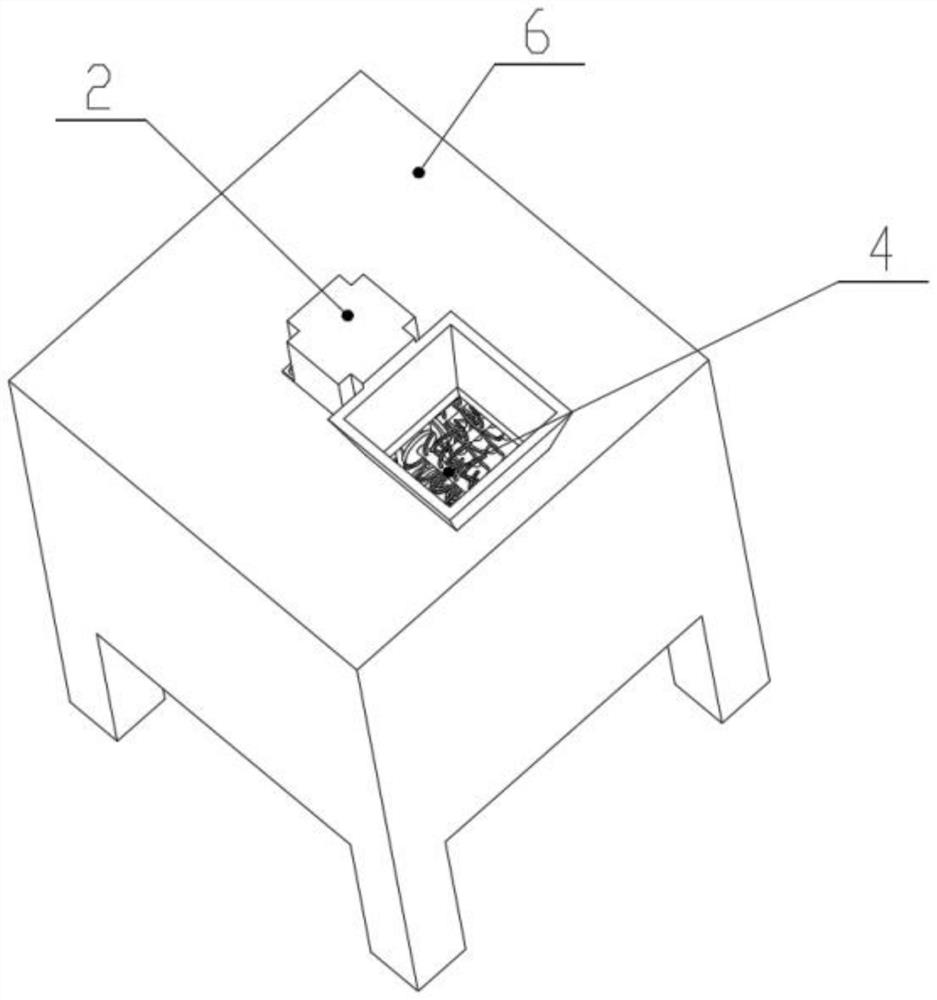

[0037] Such as figure 1 As shown, a straw cutting equipment for livestock feed processing includes a limit device 1, a servo motor 2, a transmission device 3, a cutting device 4, a screening device 5 and a support device 6, and the inner end surface of the support device 6 is fixed and clamped. The transmission device 3 is connected to the transmission device 3, and the outer end surface of the transmission device 3 is rotated and clamped with a limit device 1 for limiting, and the outer end surface of the limit device 1 is evenly and equidistantly rotated and clamped with four sets of cutting devices for cutting 4. A servo motor 2 is fixedly installed at the center of the upper end surface of the support device 6 facing the limit device 1, and a screening device 5 is fixedly installed at the bottom of the inner end surface of the support device 6. When cutting straw, the user can Start the servo motor 2 directly. At this time, the servo motor 2 can drive the internal limit de...

Embodiment 2

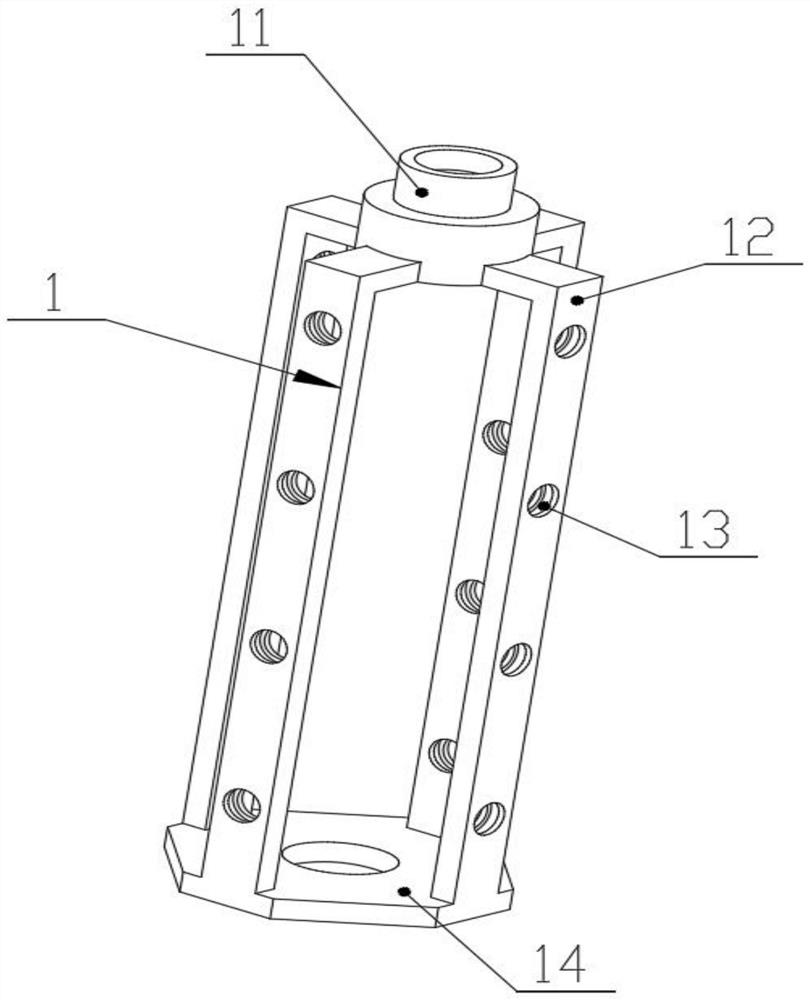

[0039] Such as Figure 1-4 As shown, as a further optimization scheme of the above-mentioned embodiment: a straw cutting equipment for livestock feed processing, including a limiting device 1, a servo motor 2, a transmission device 3, a cutting device 4, a screening device 5 and a supporting device 6, the supporting device The inner end surface of the device 6 is fixedly clamped with a transmission device 3 for transmission, and the outer end surface of the transmission device 3 is rotatably clamped with a limit device 1 for limiting, and the outer end surface of the limit device 1 is evenly and equidistantly rotated and clamped. There are four sets of cutting devices 4 for cutting. The center of the upper end surface of the supporting device 6 is fixedly installed with a servo motor 2 facing the limit device 1. The bottom of the inner end surface of the supporting device 6 is fixedly equipped with a screening device 5 . The limiting device 1 includes a fixed guide shaft 11, a...

Embodiment 3

[0041] Such as Figure 1-7 As shown, as a further optimization scheme of the above-mentioned embodiment: a straw cutting equipment for livestock feed processing, including a limiting device 1, a servo motor 2, a transmission device 3, a cutting device 4, a screening device 5 and a supporting device 6, the supporting device The inner end surface of the device 6 is fixedly clamped with a transmission device 3 for transmission, and the outer end surface of the transmission device 3 is rotatably clamped with a limit device 1 for limiting, and the outer end surface of the limit device 1 is evenly and equidistantly rotated and clamped. There are four sets of cutting devices 4 for cutting. The center of the upper end surface of the supporting device 6 is fixedly installed with a servo motor 2 facing the limit device 1. The bottom of the inner end surface of the supporting device 6 is fixedly equipped with a screening device 5 . The limiting device 1 includes a fixed guide shaft 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com