Control system and method for assisting primary frequency modulation of thermal power generating unit by electrode type electric boiler

A technology for thermal power units and control systems, applied in general control systems, control/regulation systems, computer control, etc., can solve the problem that the flexibility of electrode-type electric boilers cannot be fully utilized, the research and application of auxiliary thermal power units has not been carried out, and the impact on thermal power units has not been carried out. Safe operation and other issues to achieve the effect of prolonging the life, increasing the power consumption of the factory, and reducing the power consumption of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

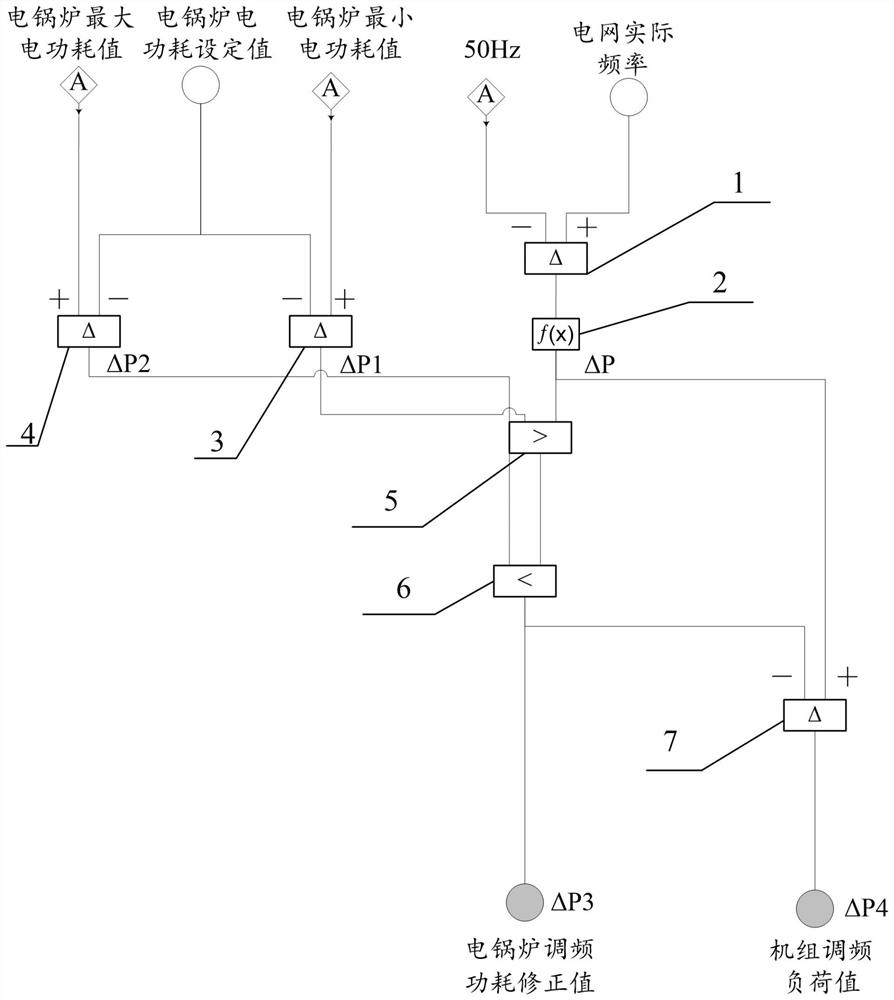

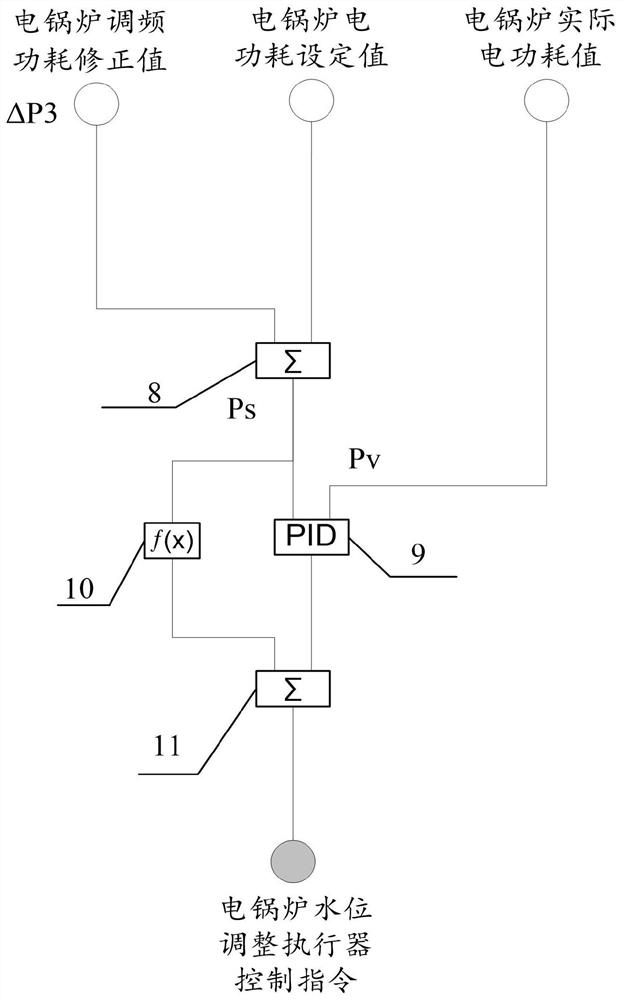

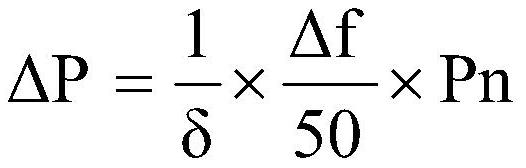

[0037] The invention proposes a control system and method that utilizes the load characteristics of an electrode type electric boiler to assist a thermal power unit in participating in primary frequency modulation control of a power grid.

[0038]In order to make the purpose, features, and advantages of the present invention more obvious and understandable, the technical solutions in the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the present invention is not limited by the following examples, and the specific implementation manner can be determined according to the technical solutions of the present invention and actual conditions. In order not to obscure the essence of the present invention, well-known methods, procedures, procedures, components and circuits have not been described in detail. In the description of the present invention, it should be understood that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com