Detection device, detection system, and detection method

A detection device and technology to be detected, applied in the direction of measurement device, measurement device casing, measurement electricity, etc., can solve problems such as inaccurate positioning and reduce work efficiency, and achieve accurate positioning, improve work efficiency, and facilitate multiple detections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

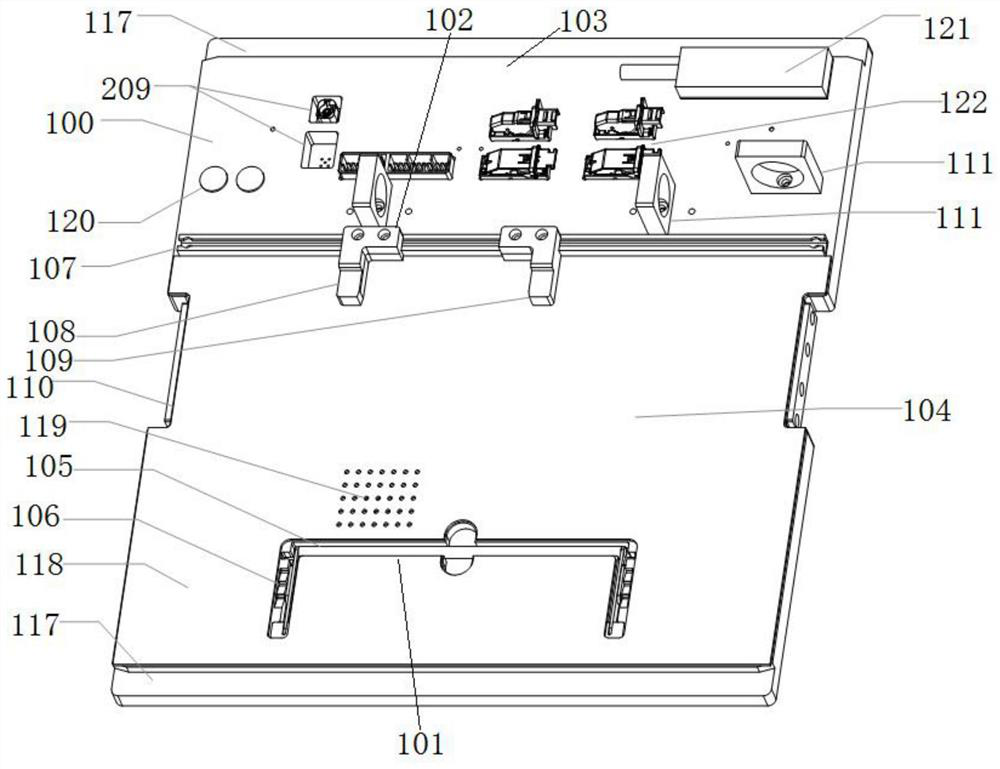

[0034] see figure 1 and figure 2 , the embodiment of the present invention provides a carrier, including a carrier body 100 for placing the product to be tested. The carrier body 100 has an angle adjustment component 101 that can adjust the inclination angle of the product to be tested and can fix the product to be tested. The clamping assembly 102 of the product to be tested, the clamping assembly 102 has a clamping section 103 that can be adjusted according to the size of the product, and the angle adjustment assembly 101 and the clamping assembly 102 are between the product to be tested. Assembly section 104 . In this embodiment, the angle of inclination of the product to be tested can be adjusted through the angle adjustment component 101, so that it can be raised to a certain height, so that the display surface of the product to be tested is in the operator's best viewing angle range, which is convenient for the operator to detect the product to be tested. In addition,...

Embodiment 2

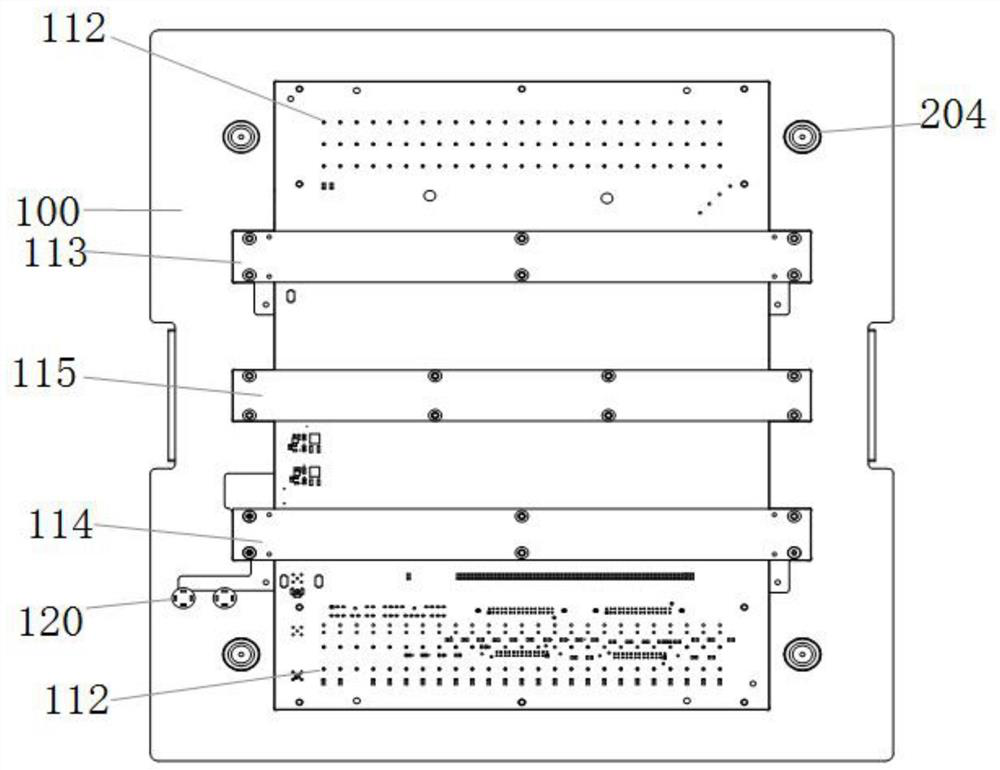

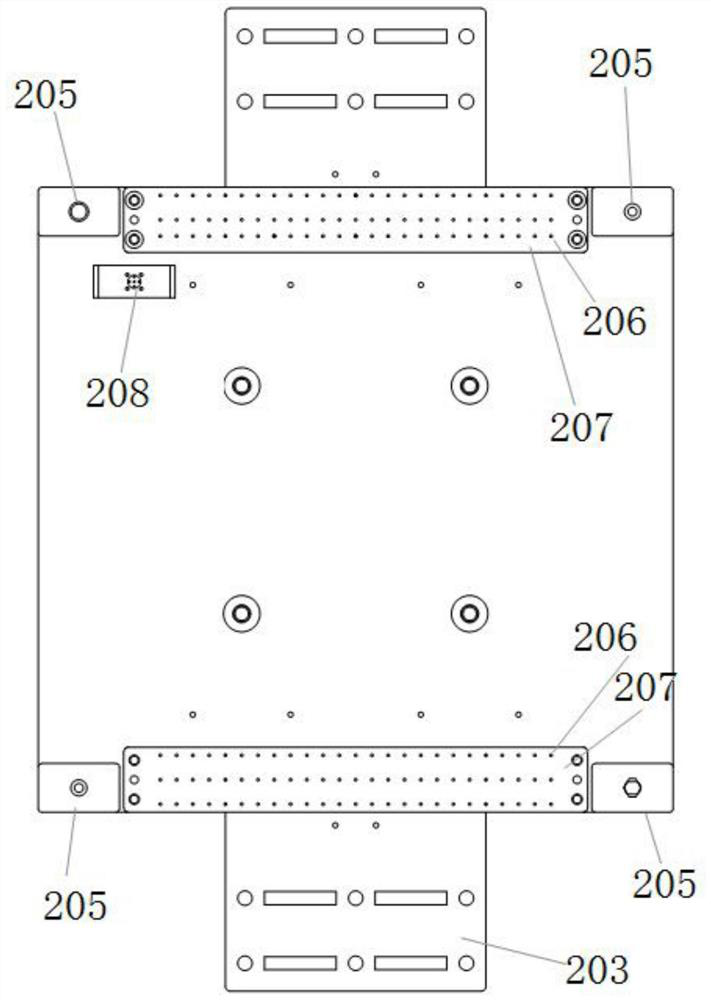

[0049] see image 3 and Figure 4 , an embodiment of the present invention provides a detection device, including a carrier for carrying a product to be detected and a detection component for testing the product to be detected on the carrier, the detection component includes a test board 200, arranged on the The test head 201 on the test board 200 and the lifting mechanism that can lift the test board 200 so that the test head 201 docks with the carrier, and the test head 201 is connected to external test equipment. In this embodiment, the existing problems in manual docking are solved by the lifting mechanism, and the working efficiency is improved. Specifically, when the carrier brings the product to be tested to the detection position, the lifting mechanism drives the test board 200 to rise, thereby completing the docking of the test head 201 and the carrier. Compared with the existing manual docking, the mechanical docking is more stable. Higher quality.

[0050] As an ...

Embodiment 3

[0060] see Figure 5 to Figure 9 , the embodiment of the present invention provides a steering device, including a body 300, the body 300 has a receiving position 301 for receiving incoming products to be rotated, and a rotating position for rotating the products sent by the receiving position 301 302 and the conveying position 303 for sending out the rotated product, the receiving position 301, the rotating position 302 and the conveying position 303 are in a straight line and the rotating position 302 is located between the receiving position 301 and the Between the delivery positions 303. In this embodiment, through the in-line arrangement of the receiving position 301, the rotating position 302 and the conveying position 303, the actions of receiving, rotating and sending away the product can be completed at one time. The whole action process is coherent, and the overall equipment does not waste the factory building take up space.

[0061] As an optimization scheme of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com