Bolt anti-loosening sleeve

A technology of anti-loosening sleeves and bolts, which is applied in the direction of bolts, screws, nuts, etc., and can solve the problems of increasing the threshold and difficulty of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention is described in further detail in conjunction with accompanying drawings and specific embodiments.

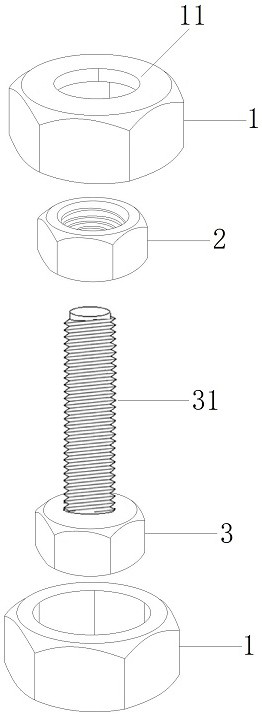

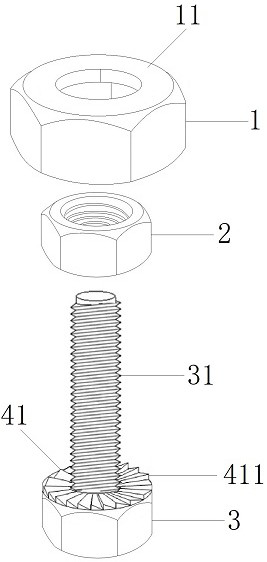

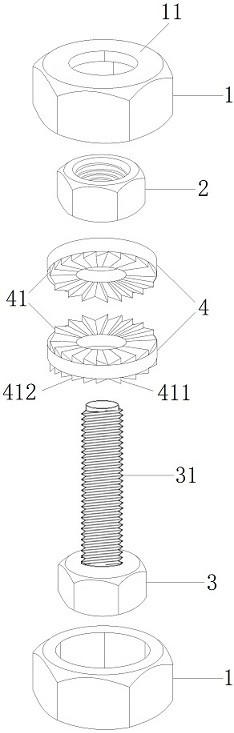

[0049] like Figure 1-32As shown, bolt anti-loose sleeve, including: anti-loose sleeve 1 is a metal tube of the hollow tube structure, the inner wall of the hollow tube is a circular hollow tube, the outer surface of the hollow tube is a polygonal column; the polygon column is six sides Structure; anti-loose sleeve 1 is open, the other end is connected to the ring panel 11, the surface center region of the loop panel 11 is provided with at least one through hole; wherein the inner passage of the circular circle panel 11 is larger than the bolt 3 screw 31. The outer diameter; the spacer 4 is a ring structure of the through hole, and at least one surface of the gasket 4 is provided with a procedure 41; the first anti-loose teeth 411 and the second anti-loose teeth 412 are arranged in the anti-loose teeth 412 Contrary to the direction of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com