Efficient plasma cutting machine

A plasma cutting machine and plasma technology, applied in the directions of plasma welding equipment, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of reducing the quality of device processing, inaccurate metal cutting position, uneven surface of cutting parts, etc. Achieve improved accuracy, ease of cleaning, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

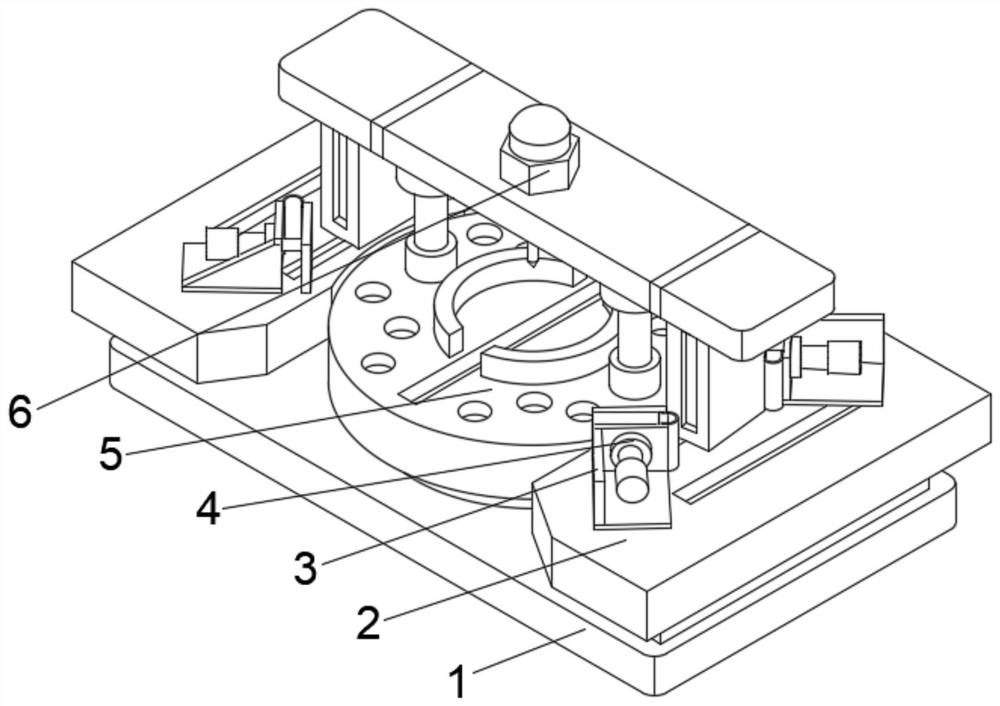

[0033] see Figure 1-2 , the present invention provides a technical solution: a high-efficiency plasma cutting machine, including a base plate 1, a cutting device 5 is fixedly connected to the top middle position of the base plate 1, a plasma cutter 6 is arranged at the top middle position of the cutting device 5, and the base plate 1 The top of the top is located on both sides of the cutting device 5 and is fixedly connected with the bearing plate 2, and the top of the bearing plate 2 is fixedly connected with the support seat 3 on both sides of the cutting device 5, and the side of the support seat 3 close to the cutting device 5 is provided with a positioning guide piece 4.

[0034] Wherein, the cutting device 5 includes a placing block 53, the bottom of the inner cavity of the placing block 53 is provided with a driving member 54, the right outer wall of the placing block 53 is fixedly connected with a stabilizing mechanism 55, and the middle position on both sides of the ...

Embodiment 2

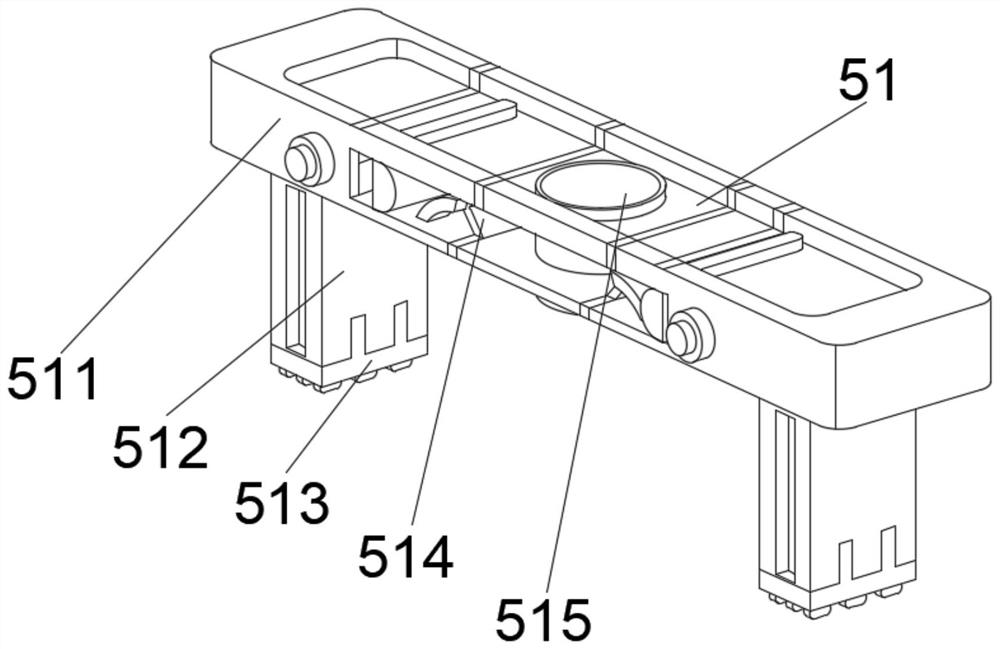

[0037] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: component 1 of the moving mechanism 51 includes a fixed connection plate 512, the bottom of the fixed connection plate 512 is fixedly connected with a slider 513, and the top of the fixed connection plate 512 is fixedly connected There is a horizontal plate 511, the top middle of the horizontal plate 511 is fixedly connected with a fixed sleeve 515, and the top of the horizontal plate 511 is fixedly connected with a swing plate 514 on both sides of the fixed sleeve 515.

[0038] Among them, the first component of the stabilizing mechanism 55 includes a protective shell 551, the middle position of the inner cavity bottom of the protective shell 551 is fixedly connected with a stabilizing block 554, the top of the stabilizing block 554 is provided with a balance fixer 552, and the inner cavity bottom of the protective shell 551 is located Both sides of the block 554 are fi...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: Component 2 of the moving mechanism 51 includes a balance beam d1, an internal solid block d3 is provided at the top middle of the balance beam d1, and the balance beam d1 The bottom is located on both sides of the inner solid block d3 with a positioning elevating rod d4, an auxiliary support d2 is fixedly connected between the top of the positioning elevating rod d4 and the balance beam d1, and the bottom of the positioning elevating rod d4 is fixedly connected with a moving plate d5.

[0042] Wherein, the second component of the stabilizing mechanism 55 includes a connection base t1, a transition piece t2 is fixedly connected to the top of the connection base t1, a casing t4 is fixedly connected to the top of the transition piece t2, and an overhanging plate t3 is arranged in the middle of the inner cavity top of the casing t4 , The top of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com