Testing equipment and testing method for wind-induced vibration and galloping performance of optical cable

A technology for testing equipment and testing methods, which is applied in the direction of measuring devices, instruments, etc., and can solve the problems that ADSS optical cables and OPGW optical cables cannot reflect the stress of ADSS optical cables or OPGW optical cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

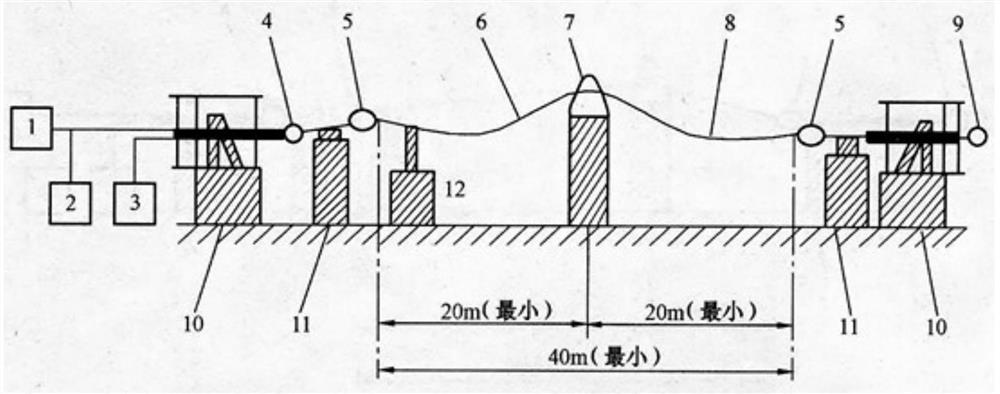

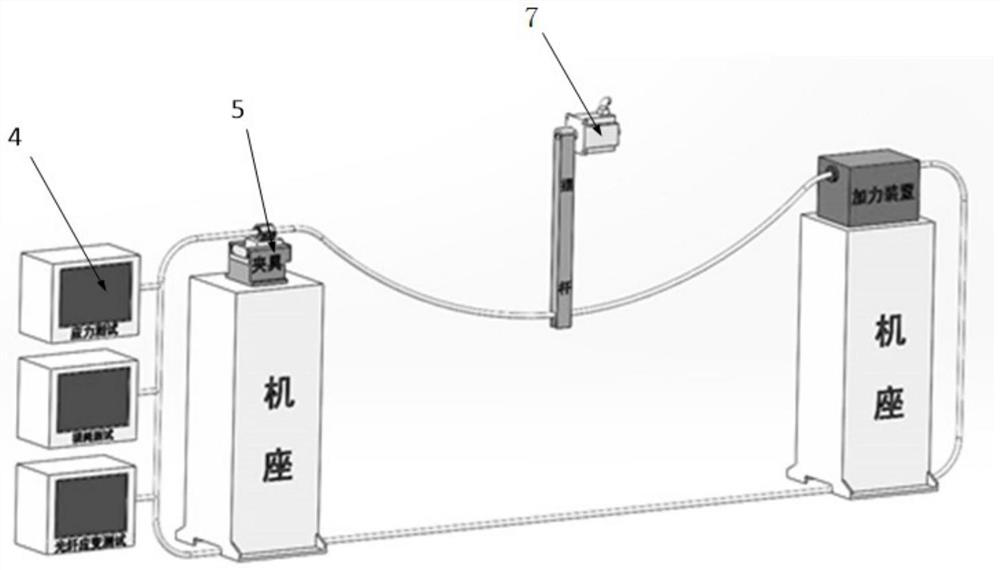

[0052] This embodiment provides a kind of test equipment for wind-induced vibration and galloping performance of optical cable, such as figure 1 , 2 shown, including:

[0053] There are two terminal supports 10, which are arranged at both ends of the test equipment;

[0054] An optical fiber connector 9 is mounted on one of the terminal supports 10 for fixing one end of the optical cable to be tested;

[0055] The force measuring mechanism 4 is installed on the other terminal support 10, and is used to measure the tensile force of the end of the optical cable to be tested;

[0056] Optical fiber dispersion test system, used to connect to the end of the optical cable to measure the change of fiber length and attenuation at the typical wavelength of the optical transmission window;

[0057] The suspension device 7 is arranged in the middle of the two terminal supports 10, and is used for arbitrarily swinging the middle position of the optical cable to be tested;

[0058] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com