Dyeing equipment suitable for knitted fabric

A technology for knitted fabrics and dyeing equipment, which is applied to the processing of textile materials, processing of textile material drums, and processing of textile material carriers. Color fastness, increasing cloth running length, reducing the effect of tension pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

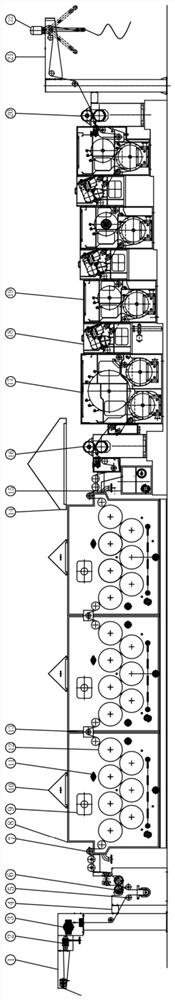

[0028] This embodiment provides a continuous tie-dyeing device suitable for knitted fabrics. refer to figure 1 , The continuous tie-dyeing equipment includes a cloth feeding device 100, a dyeing device 200, a color fixing device 300, a rerolling device 400, a washing device 500, a rerolling device 600, and a cloth outlet device 700 arranged in sequence.

[0029] Wherein, the cloth feeding device 100 is used to receive and flatten the knitted fabric to be dyed, and send the knitted fabric to the dyeing device 200 . Such as figure 2 As shown, the cloth feeding device 100 includes a cloth feeding frame 1 , a tensioner 2 , and a photoelectric plummet 3 . The cloth feeding frame 1 can realize the cloth feeding of the knitted fabric, and the knitted fabric passes through the tensioner 2 and the photoelectric centering device 3 in sequence to realize spreading and centering, so that the knitted fabric is fed into the dyeing device 2 flatly and without wrinkles.

[0030] The dyein...

Embodiment 2

[0048] Dyeing object: pure cotton knitted terry cloth.

[0049] The dye formula is as follows:

[0050] Reactive black L-D: 60g / l;

[0051] Active Red L-S: 6g / l;

[0052] Active yellow brown: 12g / l;

[0053] Caustic soda: 12g / l;

[0054] Penetrant: 4g / l;

[0055] Wherein, the solvent is water.

[0056] The dyeing process is as follows:

[0057] Weighing and chemicals.

[0058] The dye liquor is added into the feed tank of the dyeing device 200 through an automatic feeding system. Set the operating parameters of the continuous tie-dyeing equipment, including the cloth feeding speed of the cloth feeding device 100, the temperature in the color fixing box 8, the target cloth surface tension, and the like. Wherein, the temperature of setting color fixing box is 100 °. Set the residence time of the knitted fabric in the color-fixing box 8 to be 60s. The target cloth surface tension set is 1.2kg.

[0059] Start the continuous tie-dyeing equipment, so that the knitted fabr...

Embodiment 3

[0066] Dyeing object: pure cotton knitted terry cloth.

[0067] The dye formula is as follows:

[0068] Active navy blue L-3G: 30g / l;

[0069] Active Red L-S: 6g / l;

[0070] Soda ash: 20g / l;

[0071] Penetrant: 4g / l;

[0072] Wherein, the solvent is water.

[0073] The dyeing process is as follows:

[0074] Weighing and chemicals.

[0075] The dye liquor is added into the feed tank of the dyeing device 200 through an automatic feeding system. Set the operating parameters of the continuous tie-dyeing equipment, including the cloth feeding speed of the cloth feeding device 100, the temperature in the color fixing box 8, the target cloth surface tension, and the like. Wherein, the temperature of setting color fixing box is 100 °. Set the residence time of the knitted fabric in the color-fixing box 8 to be 60s. The target cloth surface tension set is 1.2kg.

[0076] Start the continuous tie-dyeing equipment, so that the knitted fabric is sequentially subjected to the pad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com