Mounting and dismounting structure of ship rudderstock and mounting and dismounting methods of ship rudderstock

A rudder stock and ship technology, which is applied in the field of installation and disassembly of ship rudder stock, can solve the problems of increased material cost and poor installation efficiency, and achieves the effects of high installation efficiency, low material cost and less installation tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

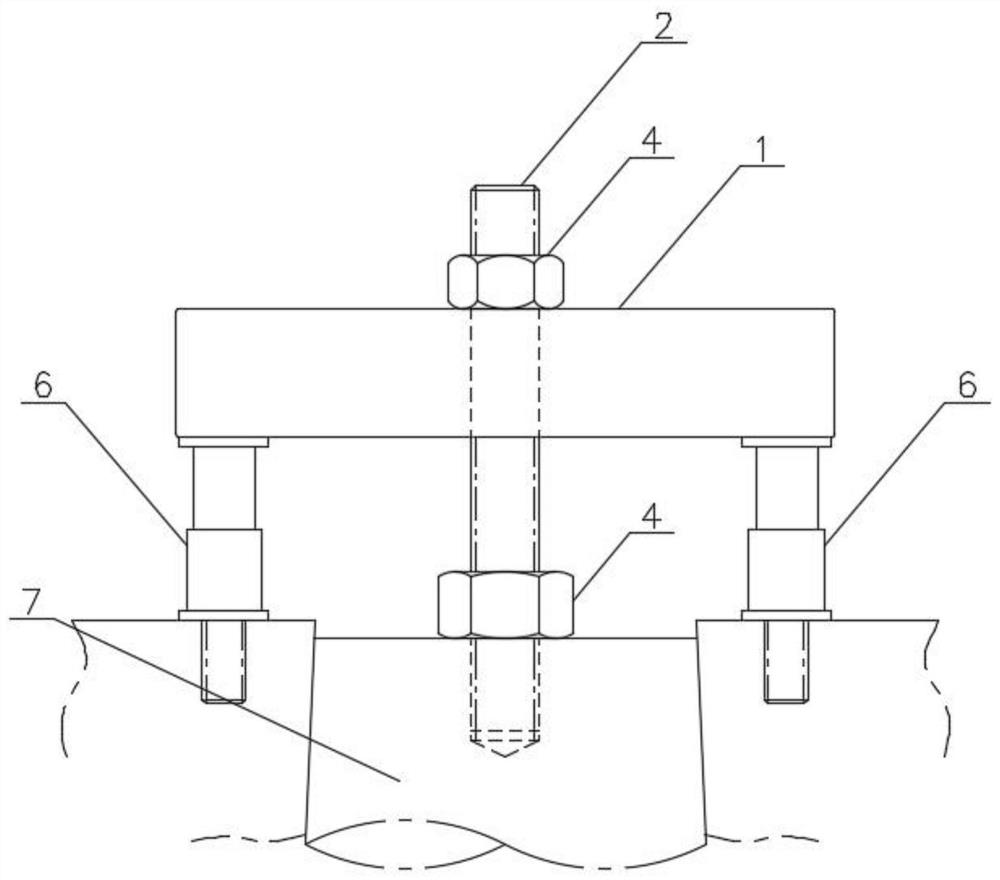

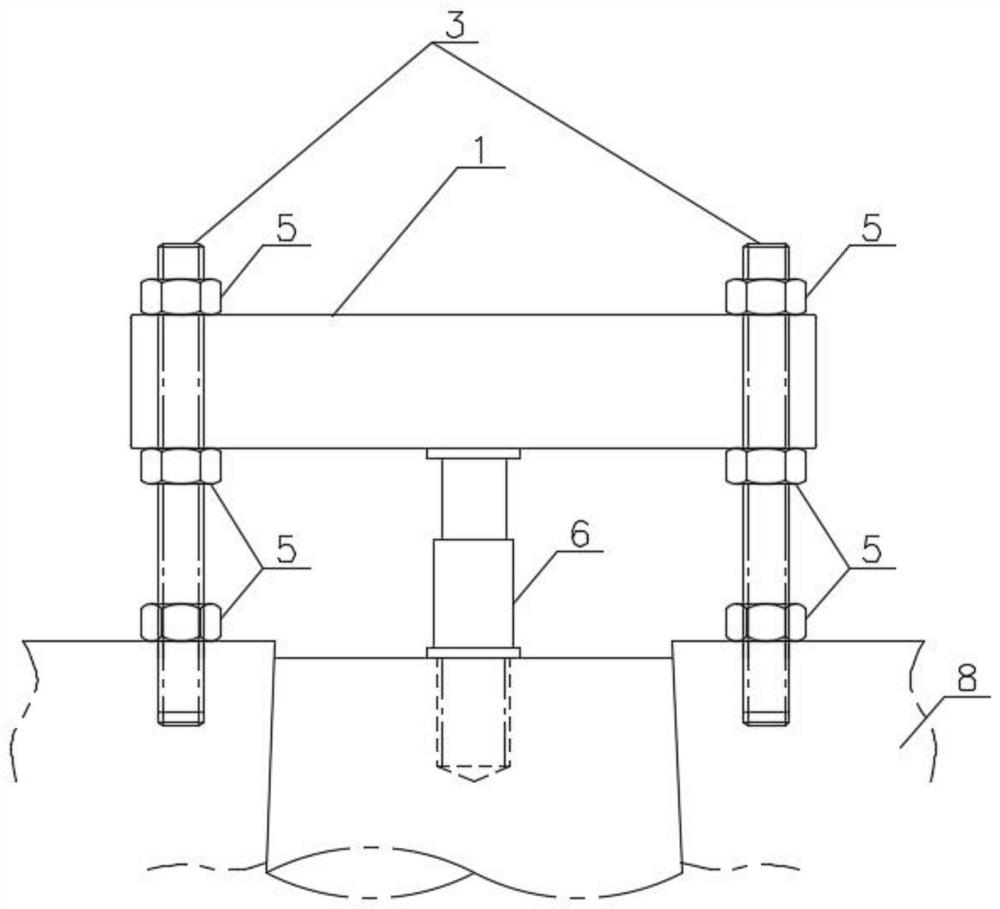

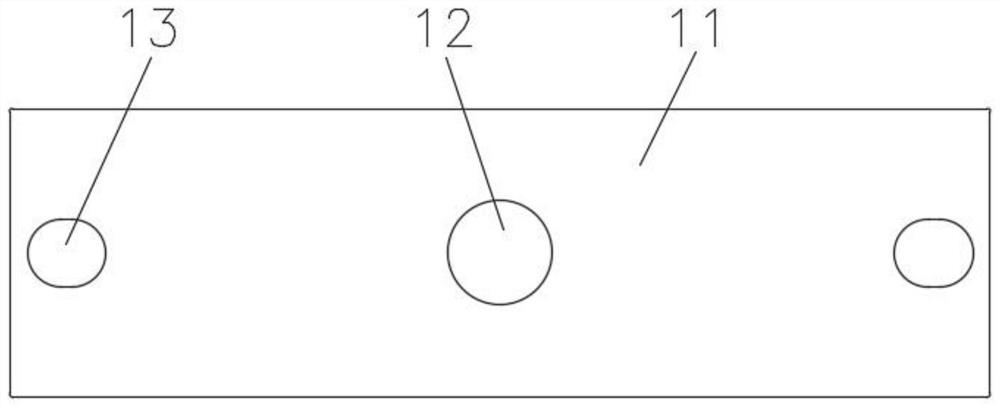

[0038] Please refer to the attached Figure 1-3 , of which, attached Figure 1-3 It shows the installation and disassembly structure of a ship rudder stock provided by the embodiment of the present application, including a rudder stock part 7 and a rudder stock seat 8, and the installation and disassembly structure is used to install the rudder stock part 7 on the rudder stock seat 8 and The rudder stock part 7 is disassembled from the rudder stock seat 8, including the iron bar 1, and the iron bar 1 is detachably connected with the rudder stock part 7 or the rudder stock seat 8 through a screw structure;

[0039] When the iron bar 1 is connected with the rudder stock 7, an interval area 1 is formed between the iron bar 1 and the rudder stock seat 8, and a hydraulic jack 6 is arranged in the interval area 1, and the hydraulic jack 6 can increase the interval of the interval area 1 ;

[0040] When the iron bar 1 is connected with the rudder stock seat 8, an interval area 2 is...

Embodiment 2

[0047] A method for installing a ship's rudder stock, the method adopts the installation and disassembly structure of the ship's rudder stock in embodiment one, comprising the following steps:

[0048] S1. Thread the bottom end of the middle screw 2 to the rudder stock 7, and then thread the first middle nut 4 on the middle screw 2, so that the bottom end of the middle nut 4 is on the top of the rudder stock 7;

[0049] S2, pass the top of the middle screw rod 2 through the middle through hole 12 of the iron bar 1, and then thread the second middle nut 4 on the middle screw rod 2, so that the bottom end of the second middle nut 4 is against the bottom of the iron bar 1 top;

[0050] S3. Place a hydraulic jack 6 in the area formed by the iron bar 1 and the rudder stock seat 8, control the extension of the hydraulic jack 6, and push the rudder stock member 7 to move relative to the rudder stock seat 8.

Embodiment 3

[0052] A dismounting method of a ship's rudder stock, the method adopts the installation and disassembly structure of the ship's rudder stock in embodiment one, comprising the following steps:

[0053] S1. Thread the bottom end of the side screw 3 to the rudder stock seat 8, and then thread two side nuts 5 on the side screw 3, so that the bottom end of one of the side nuts 5 rests on the top of the rudder stock seat 8 ;

[0054] S2, pass the top of the side screw 3 through the side through hole 13 of the iron bar 1, then thread the third side nut 5 on the side screw 3, so that the bottom of the third middle nut 4 is pushed against the bottom of the iron bar 1 top;

[0055]S3. Place a hydraulic jack 6 in the area formed by the iron bar 1 and the rudder stock member 7, and control the extension of the hydraulic jack 6 to make the rudder stock member 7 move relative to the rudder stock seat 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com