Production system for adhesive used forwoundplast

A production system and technology for Band-Aid, applied in the directions of dissolving, mixer, chemical instrument and method, etc., can solve the problems of low efficiency, inconvenient operation of operators, uneven mixing of adhesive for Band-Aid, etc., to improve uniformity, avoid The effect of uneven mixing in layers and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

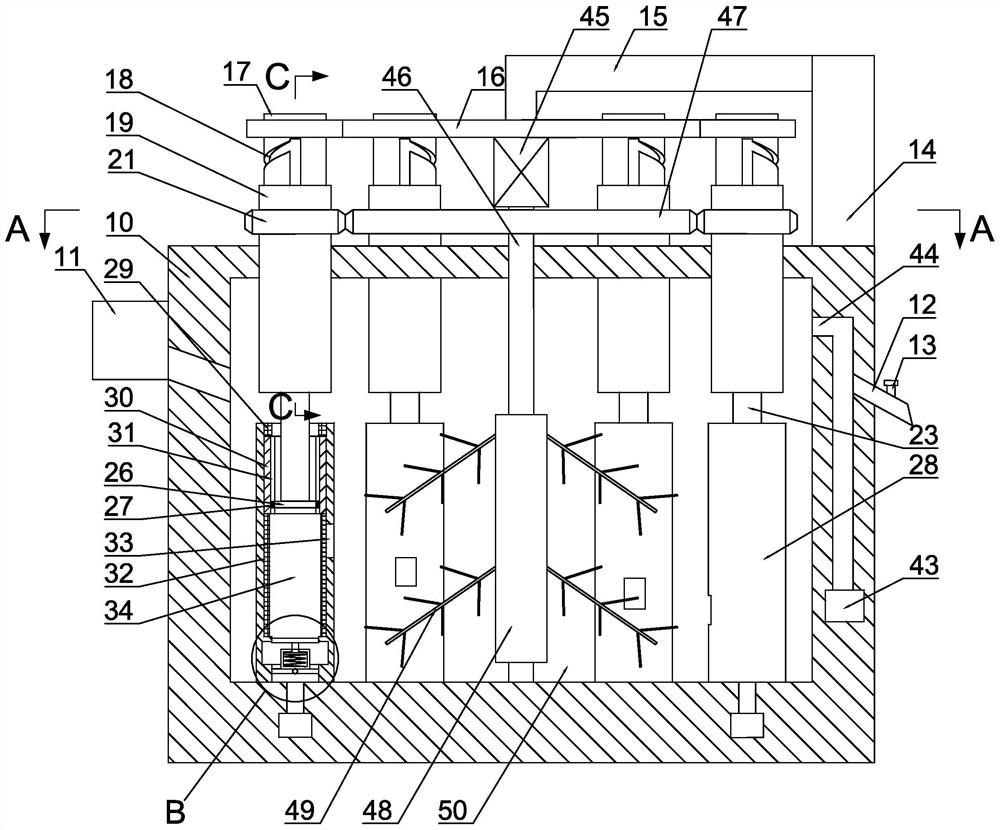

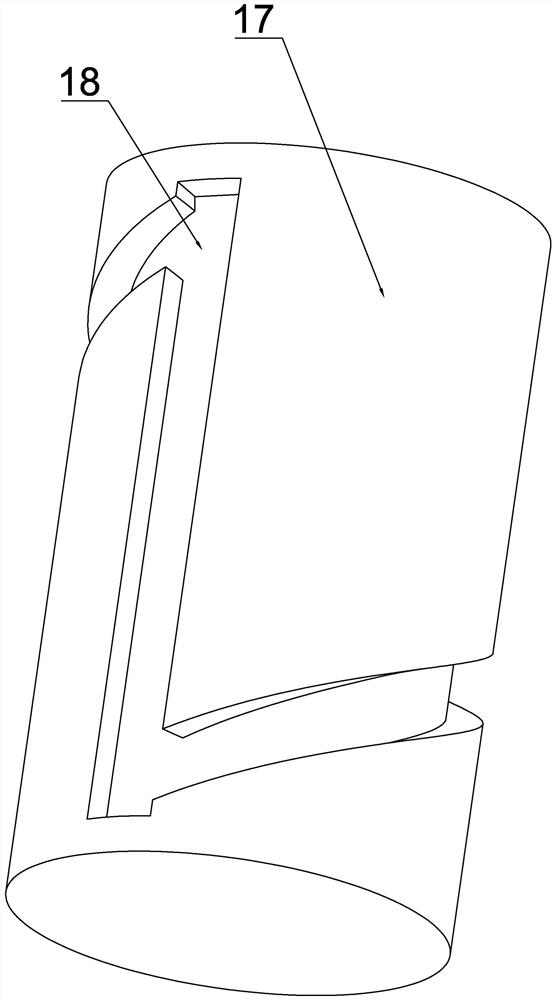

[0025] Such as figure 1 , image 3 As shown, a production system for band-aid glue includes a housing 10, and a power device is provided on the upper side of the housing 10. The power device provides power for stirring and mixing raw materials. Support plate 14, the left side of support plate 14 upper end is fixedly provided with support 15, and the support plate 15 lower end is fixedly provided with fixed plate 16, and the outer end of fixed plate 16 slides evenly along the circumferential direction and is provided with six transporting rotating shafts 17, each transporting material rotating shaft The outer surface of 17 is provided with a circuit chute 18, and the upper side wall of the housing 10 is uniformly rotated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com