Fermented malt beverage having beer taste

A malt beverage and beer-flavored technology, which is applied in the fields of beer fermentation method, preparation of alcoholic beverages, brewing of beer, etc., can solve problems such as lack of taste, and achieve the effect of excellent refreshment and excellent preference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

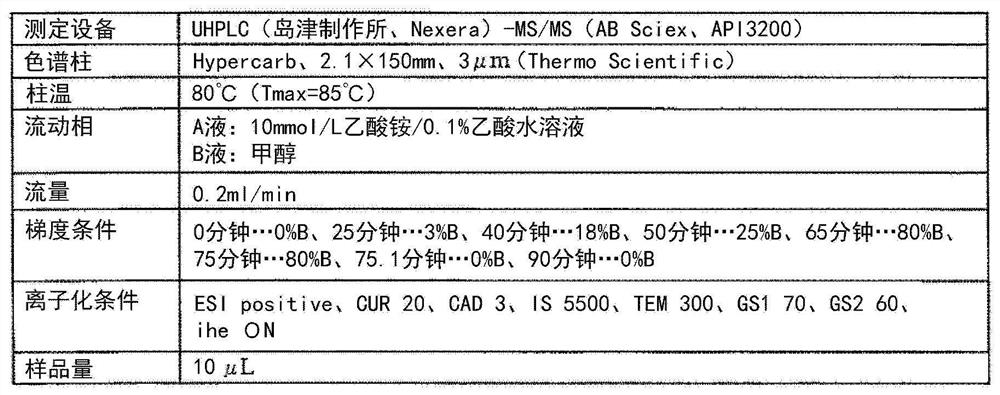

Method used

Image

Examples

Embodiment 1

[0061] [Manufacturing method of beer-taste fermented malt drink]

[0062] Put crushed malt, water and corn starch into the feeding kettle, gelatinize at 70°C, and liquefy at 100°C. Then, crushed malt, enzymes, and warm water are put into the feeding tank, and after the protein is rested at about 55°C, the liquid is transferred from the feeding tank to the feeding tank, and saccharification is carried out at a temperature in the range of 60 to 76°C. This saccharified solution was filtered with a Reuther filter (ロイター) as a lauter tank, then transferred to a boiling kettle, added with hops, and boiled for 60 minutes. After boiling, warm water of the evaporation amount was added, and after removing thermal coagulation (thermal bluble) in a vortex tank, it was cooled to 10° C. using a plate cooler to obtain cold wort.

[0063] Brewer's yeast was added to this wort, and after fermenting at about 10 degreeC for 7 days, brewer's yeast was removed. After changing the tank and allowin...

Embodiment 2

[0090] Crushed malt, enzymes, and warm water are put into a feeding trough, and after the protein is rested at about 55°C, saccharification is carried out at a temperature in the range of 60°C to 76°C. This saccharified solution was filtered with a Ruether filter serving as a lauter tank, then transferred to a boiling kettle, bitter hops were added, and the mixture was boiled for 60 minutes. After boiling, warm water of the evaporated amount was added, and after removing thermally coagulated matter in a vortex tank, it was cooled to 10° C. using a plate cooler to obtain cold wort.

[0091] Brewer's yeast was added to this wort, and after fermenting at about 10 degreeC for 7 days, brewer's yeast was removed. After changing the tank and aging for 7 days, it was cooled to about -1°C and stabilized for 14 days. Then, after adding degassed water and diluting, it filtered using diatomaceous earth, and obtained the wort fermentation liquid.

[0092] Then, the obtained wort fermenta...

Embodiment 3

[0098] The concentration of succinic acid was diluted to 30 ppm by adding a predetermined amount of degassed water to the dealcoholized wort fermented liquid obtained in Example 1. The isomerized hop extract was added so that the bitterness value would be 20 BU. Thereafter, predetermined amounts of dextrin and pyruvic acid were added so that the true extract concentration would be 5.0% and the pyruvic acid concentration would be 40 ppm. In addition, carbon dioxide was dissolved so as to have a gas volume of 2.9, and the pH was further adjusted with phosphoric acid so as to have a pH of 3.9, whereby a beer-taste fermented malt drink was obtained. This is referred to as sample 3-1. On the other hand, a predetermined amount of degassed water, pyruvic acid, and succinic acid were added to the dealcoholized wort fermentation broth to dissolve carbon dioxide so that the gas volume would be 2.9 Gas Volume, and the pH was further adjusted to 3.9 with phosphoric acid. The pH was adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com