Large-dip-angle coal seam gob-side entry retaining roadside filling supporting method

A technology of large inclination and coal seam, which is applied in the directions of backfill, earthwork drilling, safety devices, etc., can solve the problems of sliding or overturning of the backfill body beside the road, and the increase of gravitational force, and achieves good roof connection effect, guarantee effect, material A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

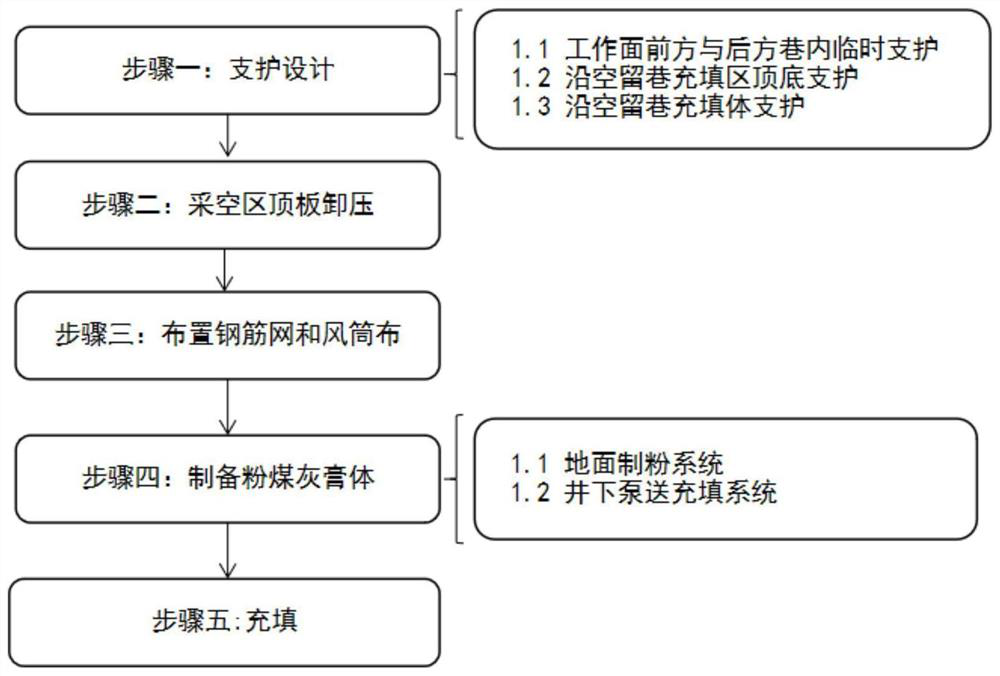

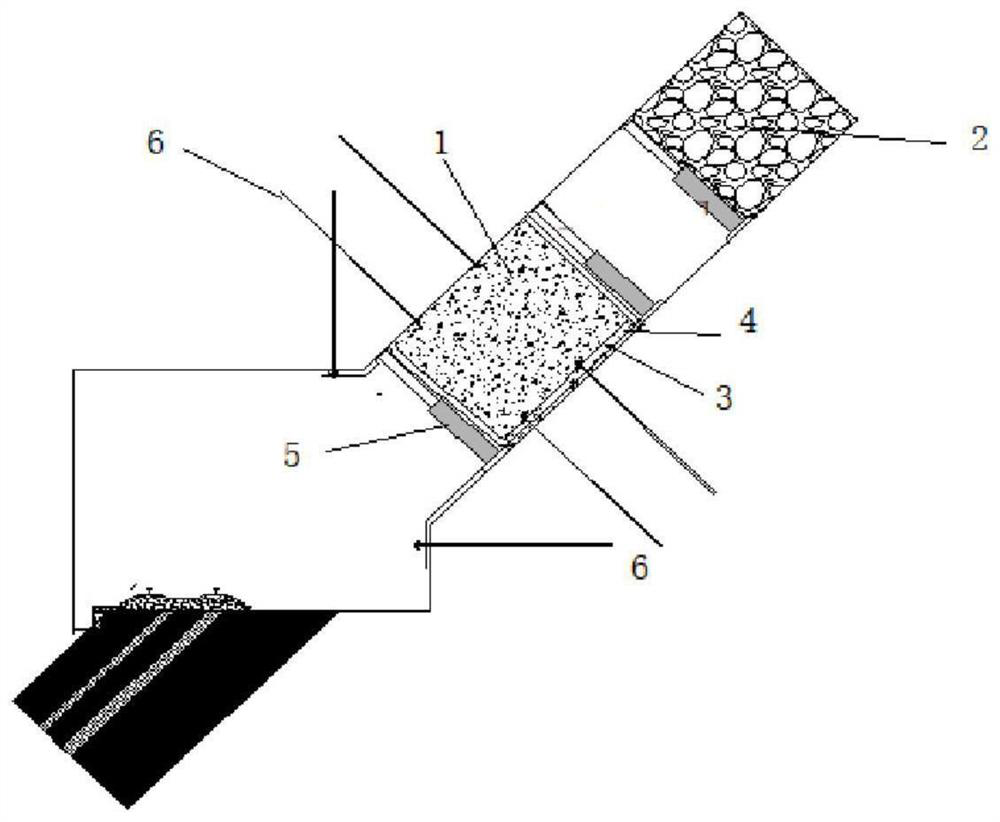

[0041] This embodiment provides a method of filling and supporting the side of the gob-side entry retaining in a large-inclination coal seam:

[0042] Step 1: Advance with the coal mining face. At the same time, a 1.2m hinged roof beam and a single hydraulic prop 5 are erected within the range of the 20m roadway in front of the coal mining face 15 to temporarily strengthen the rear roadway. The range is about 100m for the lag support.

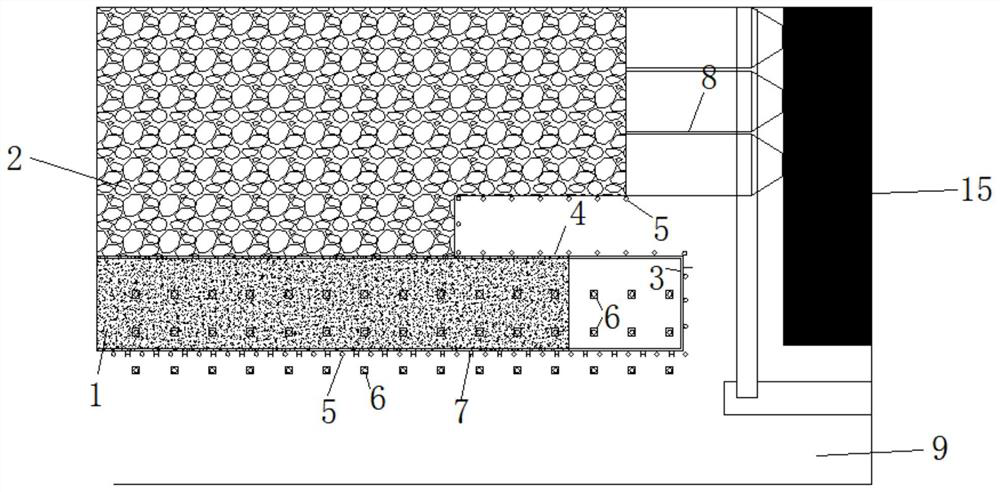

[0043] Step 2: After the temporary support of the roadway described in step 1 is completed, two anchor rods 6 are arranged above the top plate of the filling body. The anchor rods are 0.5m away from the edge of the filling body. In order to fix the reinforcement mesh 4, arrange a row of anchor rods 6 near the filling body on the roof of the tunnel. In order to strengthen the top plate and prevent the bottom plate from slipping, two anchor rods 6 are arranged above the bottom plate of the filling body. Corresponding. In order to fix the rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com