High-strength energy-saving building formwork and assembling method thereof

A building formwork, high-strength technology, applied in the direction of building, building structure, formwork/formwork/work frame, etc., to achieve the effect of tight connection, convenient operation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

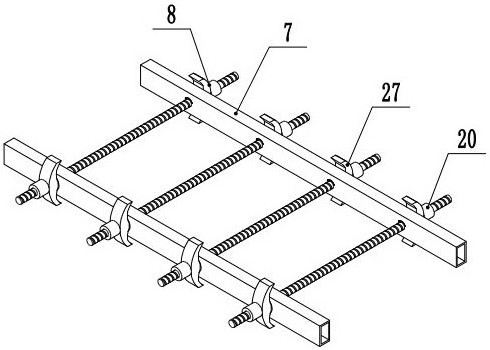

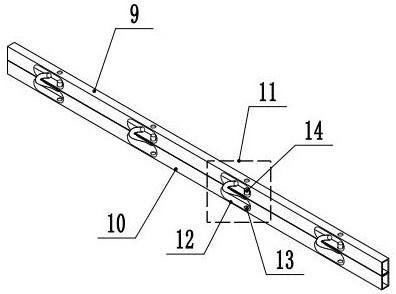

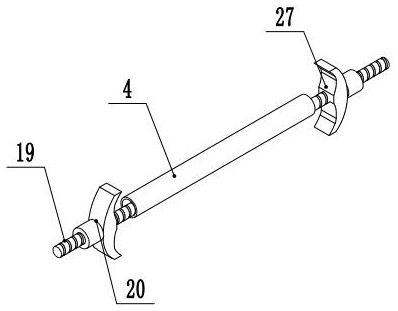

[0042] Such as figure 1 As shown, a high-strength energy-saving building template includes a first cover 1 and a second cover 2 with the same structure and mutual symmetry, and several connecting devices for connecting the first cover 1 and the second cover 2 3, and, the positioning member 4 arranged between the first cover 1 and the second cover 2; the first cover 1 and the second cover 2 each include a number of cover plates 5, and the connecting The fixing part 6 of the cover plate 5 is described above. The positioning part 4 is in the shape of a tube as a whole, and is used to be sleeved on the screw rod 19 between the first covering part 1 and the second covering part 2, so as to realize the adjustment of the distance between the first covering part 1 and the second covering part 2 Limitation, when the building formwork is disassembled, the positioning parts will not be taken out, but will be poured into the concrete, and integrated with the building board to make the bu...

Embodiment 2

[0053] Such as Figure 11 As shown, the building formwork is L-shaped. Based on the basic model of the building formwork described in Embodiment 1, the first covering 1 and the second covering 2 between a plurality of building formworks can be spliced with each other through the fixing member 6 , and when the connection of the first cover 1 or the second cover 2 is not enough, the gap is supplemented by the splicing plate 28 to realize the connection between the adjacent first cover 1 or the second cover 2 . The splicing plate 28 is used to supplement the length direction or width direction of the first covering part 1 or the second covering part 2 when the shape of the building formwork needs to be assembled.

[0054] When assembling, the long side of the L shape is formed by connecting multiple building templates. When setting the short side of the L shape, the first covering part 1 or the second covering part 2 of the building formwork is spliced first. If the first cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com