A kind of modularized substation to construct concrete prefab and construction method thereof

A technology for concrete prefabricated parts and substations, which is applied in construction, artificial islands, water conservancy projects, etc., can solve problems such as restricting the rapid development of substation construction, reduce risks and overall construction difficulty, speed up construction progress, and facilitate standardized construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

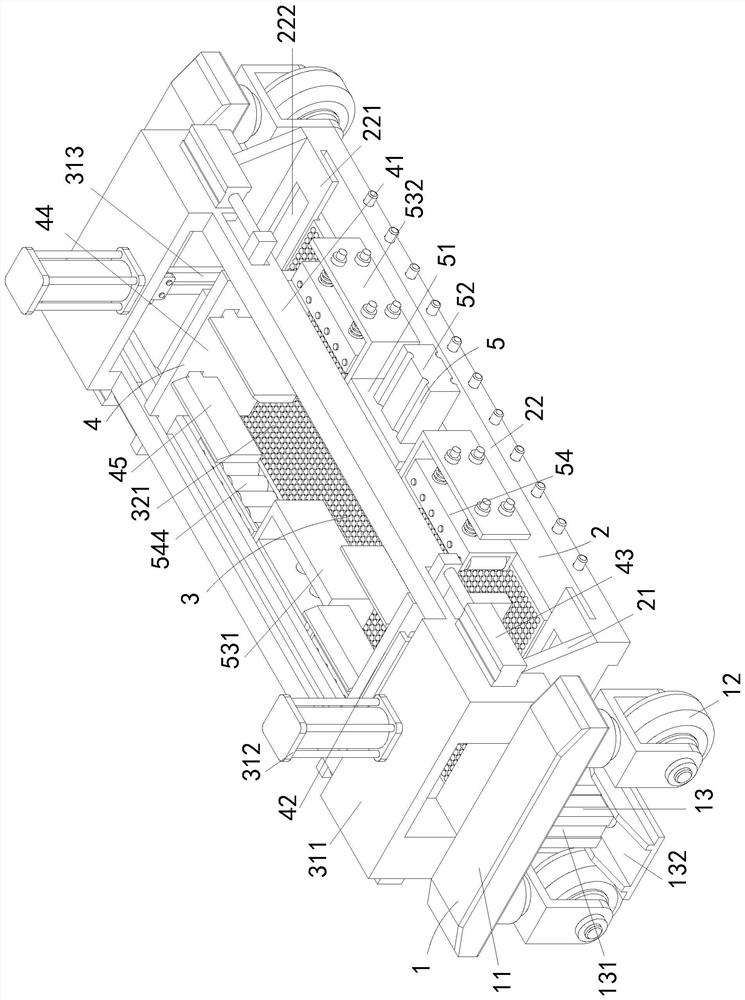

[0035] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention will be described in further detail, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and It is helpful for its implementation, but not as a limitation of the present invention.

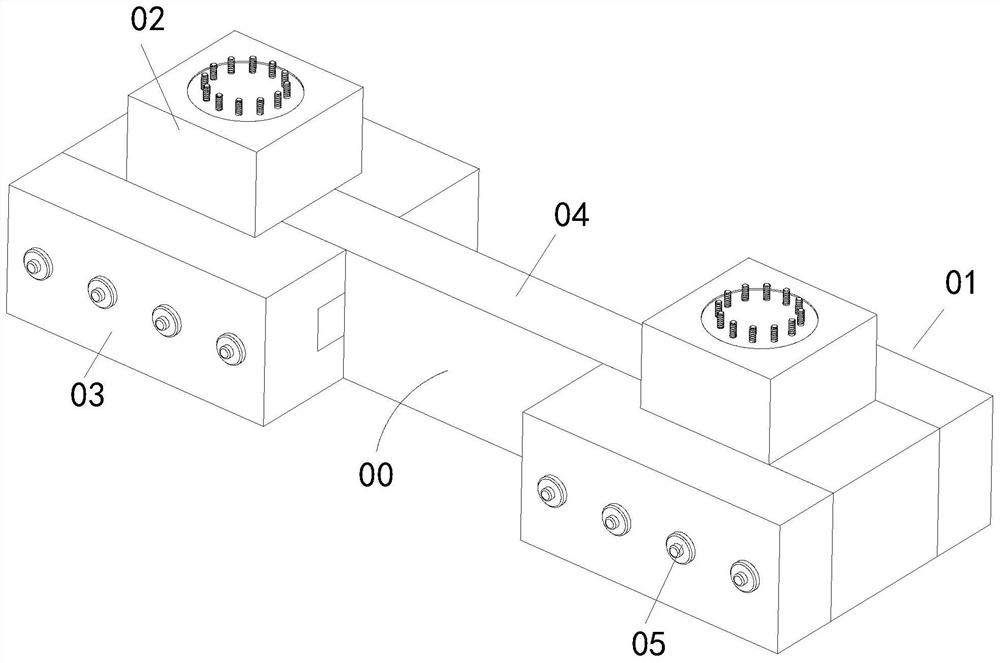

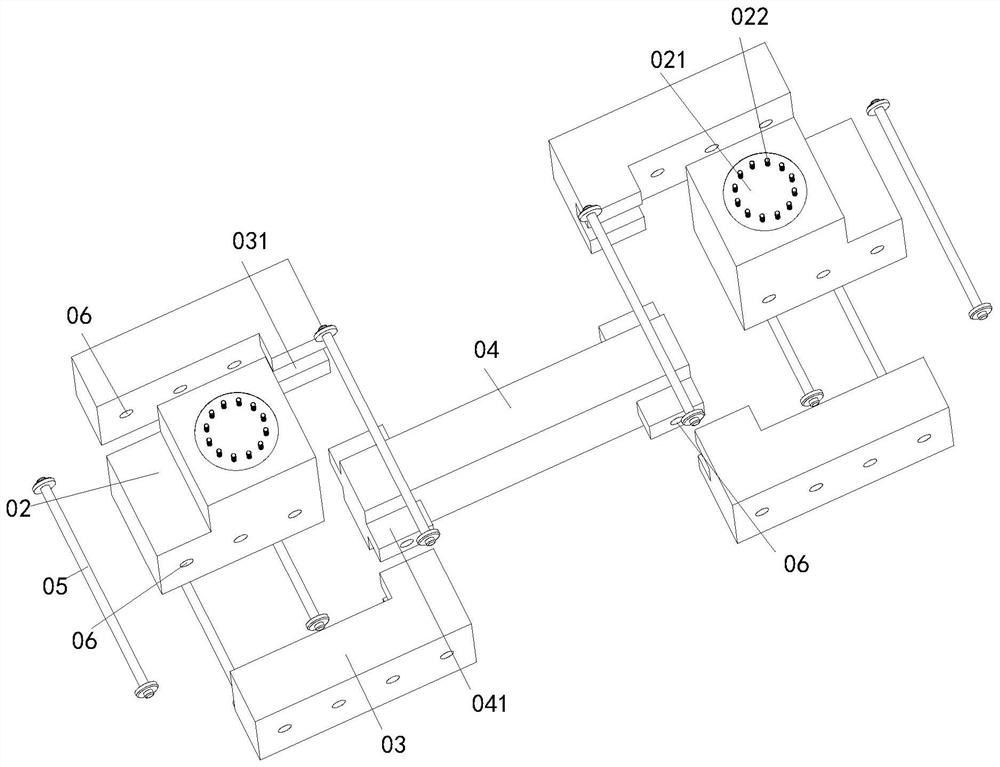

[0036] like figure 1 and figure 2 As shown, a modular substation construction concrete prefabricated part includes two unilateral foundation members 01 arranged in mirror images opposite each other, a foundation bridge 04 bridged between the two unilateral foundation members 01, and a number of prestressed tendons 05; The side base member 01 includes a main base member 02 and two side clip members 03. The main base member 02 has a stepped block structure. The top of the main base member 02 is provided with a pre-embedded flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com