Torsion spring and twisted rope winding drum assisting in winding up

A torsion spring and twisted rope technology, applied in the field of auxiliary hoisting devices, can solve problems such as inability to adjust, large torque, etc., and achieve the effect of compact structure, high torque, compact structure and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

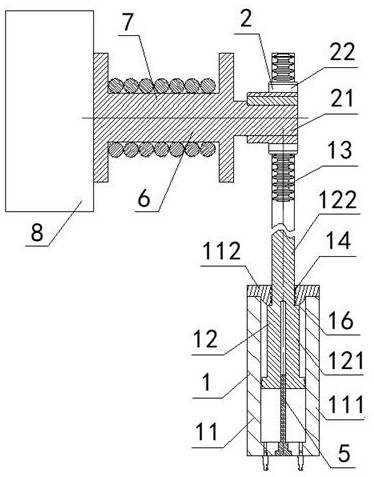

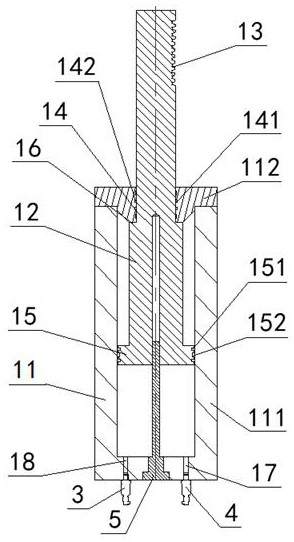

[0058] A torsion spring, the torsion spring includes an energy storage assembly 1 and a rotation assembly 2, the energy storage assembly 1 and the rotation assembly 2 are in transmission cooperation; the energy storage assembly 1 includes a closed cylinder 11 and a piston rod 12, the The inside of the cylinder 11 is provided with a piston 15, the piston 15 is in sealing fit with the inner wall of the cylinder 11, the piston 15 is fixedly connected with one end of the piston rod 12, and the other end of the piston rod 12 passes through the cylinder 11 and connects with the cylinder 11. The rack 13 is fixedly connected; the rotating assembly 2 includes a rotating shaft 21 and a cylindrical gear 22, the cylindrical gear 22 is fixedly arranged on the rotating shaft 21, and the cylindrical gear 22 meshes with the rack 13; the cylinder 11 includes a cylinder seal cover 112 and a cylinder 111 with an opening at one end, the cylinder sealing cover 112 is in sealing fit with the opening...

Embodiment 2

[0060] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0061] One end of the cylinder body 111 far away from the cylinder sealing cover 112 is provided with an inflation port 17 and a detection port 18, the inflation port 17 is provided with an inflation valve 4, and the detection port 18 is provided with a pressure sensor 3; A piston displacement sensor 5 is arranged between the charging port 17 and the detection port 18 .

Embodiment 3

[0063] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

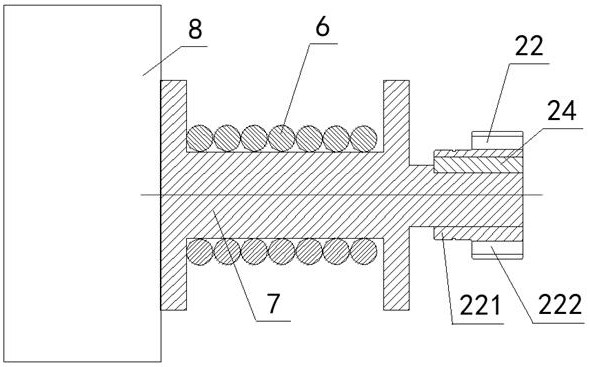

[0064]The rotating cylinder 7 is also provided with a reduction mechanism 23, and the rotating shaft of the rotating cylinder 7 is connected with the rotating shaft 21 and the cylindrical gear 22 through the reducing mechanism 23; the cylindrical gear 22 includes a gear inner ring 221 and a gear outer ring 222. The outer gear ring 222 is fixedly disposed outside the inner gear ring 221 , and the inner gear ring 221 is fixedly connected to the rotating shaft 21 through the connecting key 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com