Environment design model grinding device

A technology for designing models and environments, applied in grinding/polishing safety devices, grinding machines, abrasives, etc., can solve problems such as reduced grinding effect, damage to the environment, and occurrence of dust, so as to improve the grinding effect, protect the air environment, and protect health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

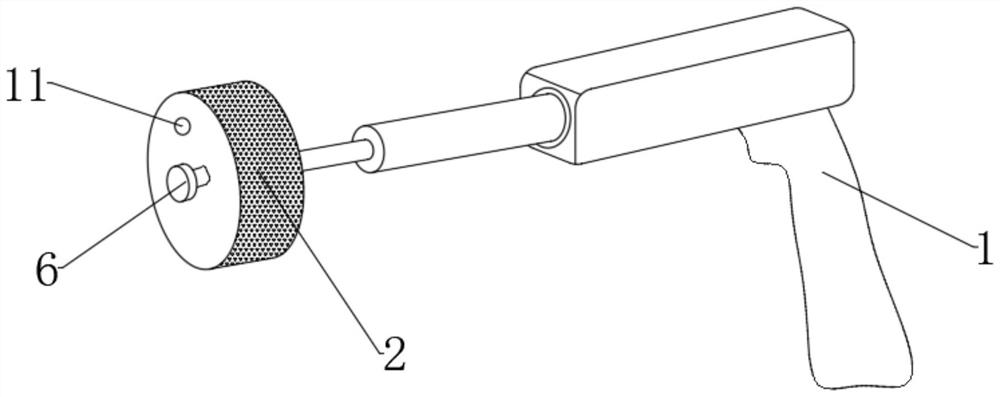

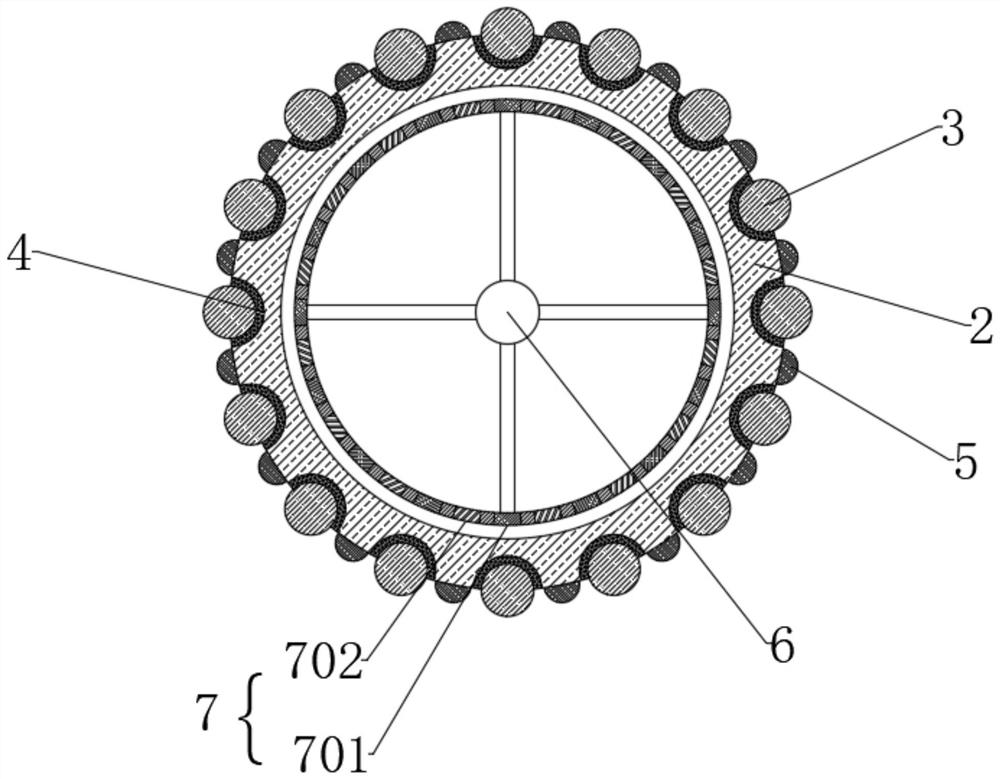

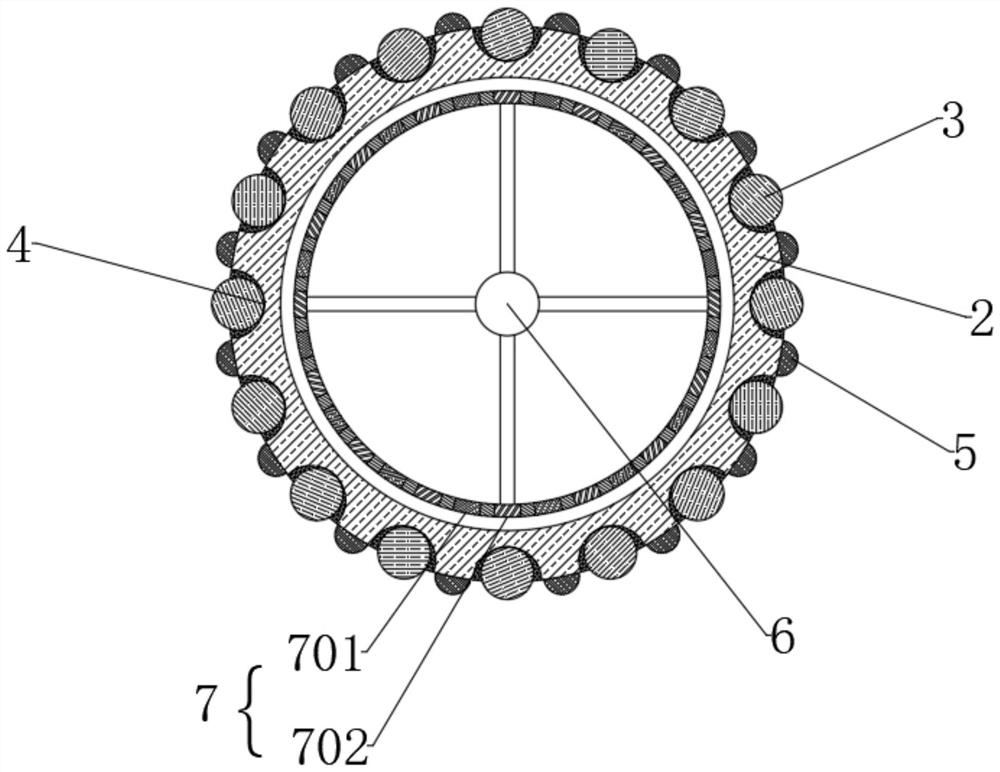

[0046] See Figure 1-9 A sharpening device model design environment, including hand-held sander body 1, see Figure 1-3 , A handheld grinding machine main body 1 is connected to the output shaft of the grinding disc 2, disc sander 2 has a hollow structure, the inside of the sanding disk 2 filled with water, see Figure 9 Side walls sanding disk 2 defines a filling opening 11, is to facilitate adding water, and the filling opening 11 has a threaded plug, to prevent water leakage, sanding sidewall insert fixed disc 2 is provided with a plurality of equally spaced crude grinding particles 3, and the crude sanding particles between the inner wall 3 is fixedly connected to the sanding disk 2 has adjustable cushion 4, see Image 6 Adjusting cushion 4 comprises a hollow reticulated elastomeric matrix 401 and a water-absorbing filler 402, the elastic substrate 401 and the absorbent filling body 402 interpenetration connection, elastomeric matrix 401 coarse grinding particles 3 to provide proj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com