Preparation method of high-purity silicon carbide and corresponding high-purity silicon carbide

A high-purity silicon carbide, high-purity technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve unfavorable environmental protection, physical mixing is difficult to achieve sufficient uniformity, and the particle size of silicon powder and carbon powder is not uniform. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

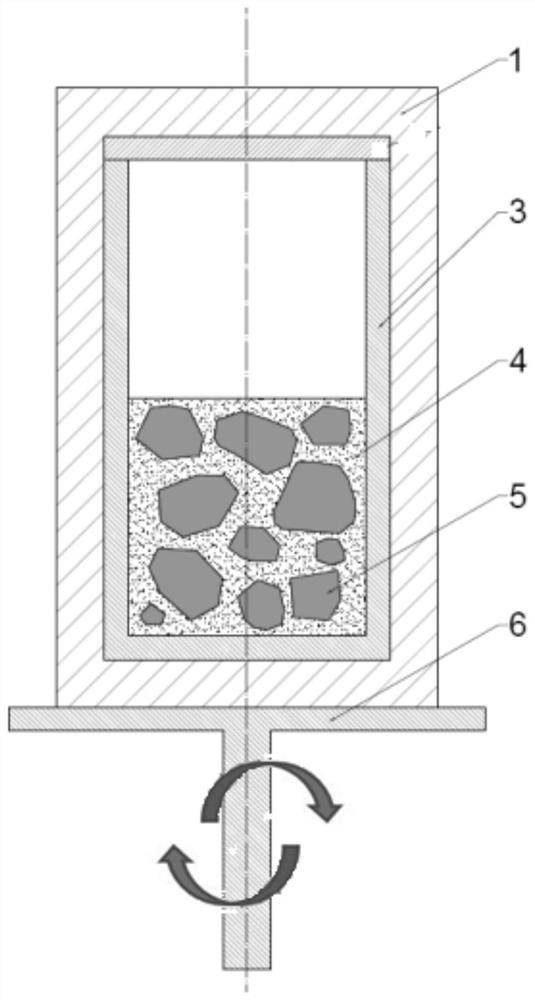

[0065] Such as figure 1 Shown, a kind of high-purity silicon carbide preparation method comprises the following steps:

[0066] S1, placing the high-purity carbon powder 4 in the graphite crucible 3, and using a high-temperature vacuum method to purify the high-purity carbon powder 4;

[0067] S2. Put the bulk silicon 5 into the graphite crucible 3, heat to melt the bulk silicon 5, rotate the graphite crucible 3 to mix the high-purity carbon powder 4 and the bulk silicon 5 evenly, and react to synthesize high-purity silicon carbide.

[0068] This application uses bulk silicon 5 instead of silicon powder, whose purity is much higher than that of silicon powder; after the bulk silicon 5 melts into liquid silicon, the graphite crucible 3 rotates at a high speed to form convection inside the silicon solution, resulting in high purity. The carbon powder 4 can be evenly distributed in the silicon solution, and can form high-purity, high-synthesis high-purity silicon carbide after c...

Embodiment 2

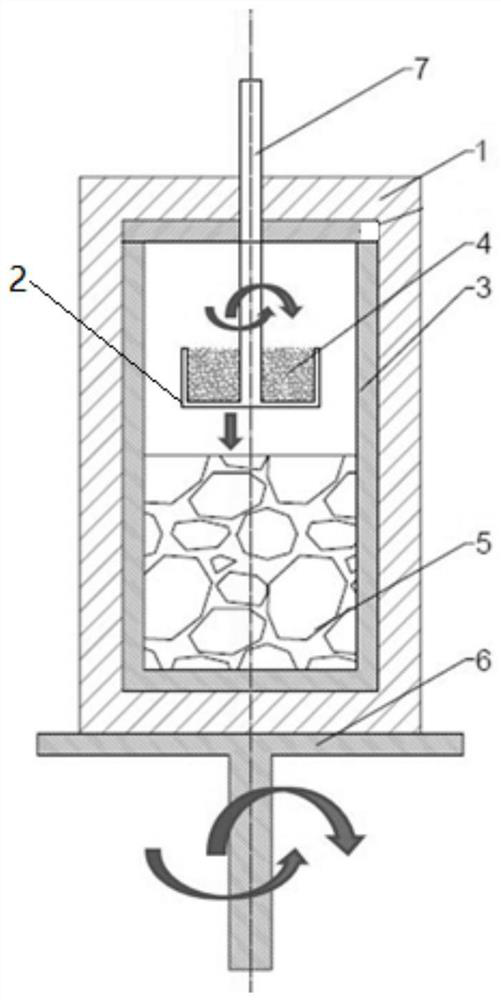

[0093] Such as figure 2 As shown, this embodiment discloses a method for preparing high-purity silicon carbide, comprising the following steps:

[0094] S1, placing the high-purity carbon powder 4 in the graphite lifting crucible 2, and purifying the high-purity carbon powder 4 by a high-temperature vacuum method;

[0095] S2. Put the massive silicon 5 into the graphite crucible 3, heat the massive silicon 5 to melt, the graphite lifting crucible 2 descends, and the purified high-purity carbon powder 4 is mixed with silicon, and the graphite crucible 3 and the graphite lifting crucible 2 are rotated , mix high-purity carbon powder 4 and massive silicon 5, the molar ratio of high-purity carbon powder and massive silicon is 1:1, lift the graphite lifting crucible 2, and obtain high-purity silicon carbide after cooling down.

[0096] This application uses bulk silicon 5 instead of silicon powder, and the purity of bulk silicon 5 is much higher than that of silicon powder; Conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com