High-precision multi-dimensional adjustment alignment system and method for optical fiber sensor packaging

An optical fiber sensor and multi-dimensional adjustment technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that the coating surface is easy to turn over, hard to put down, and affect production efficiency, etc., to achieve short alignment adjustment time, accurate adjustment alignment, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

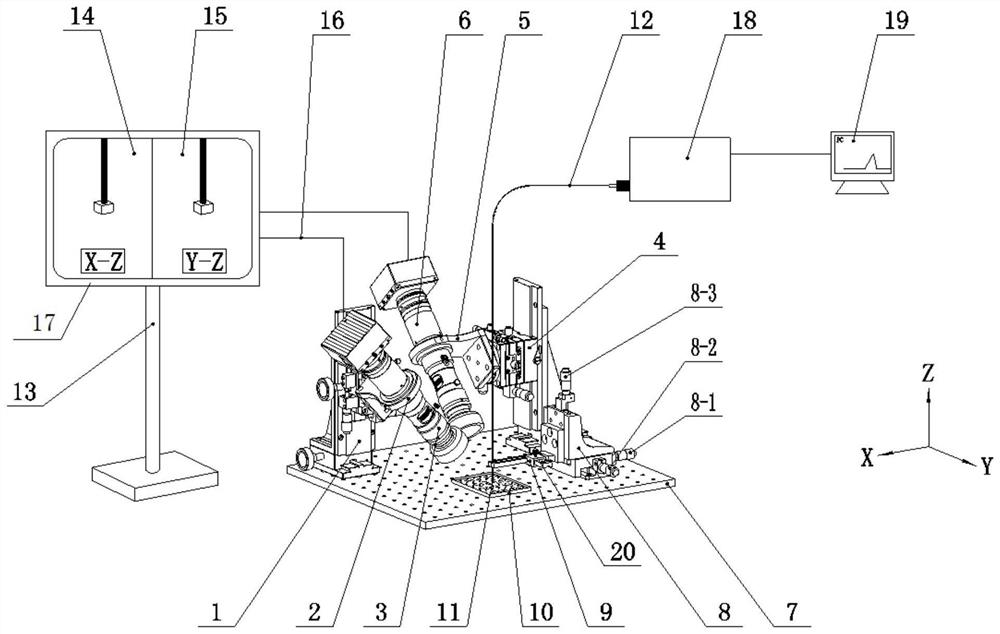

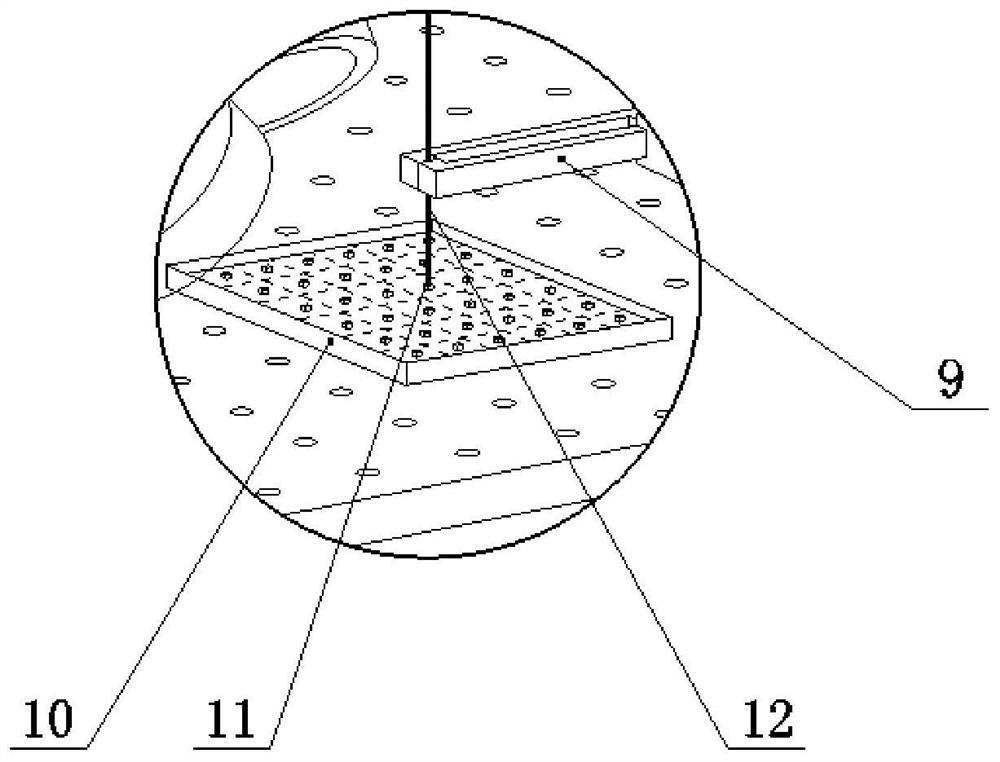

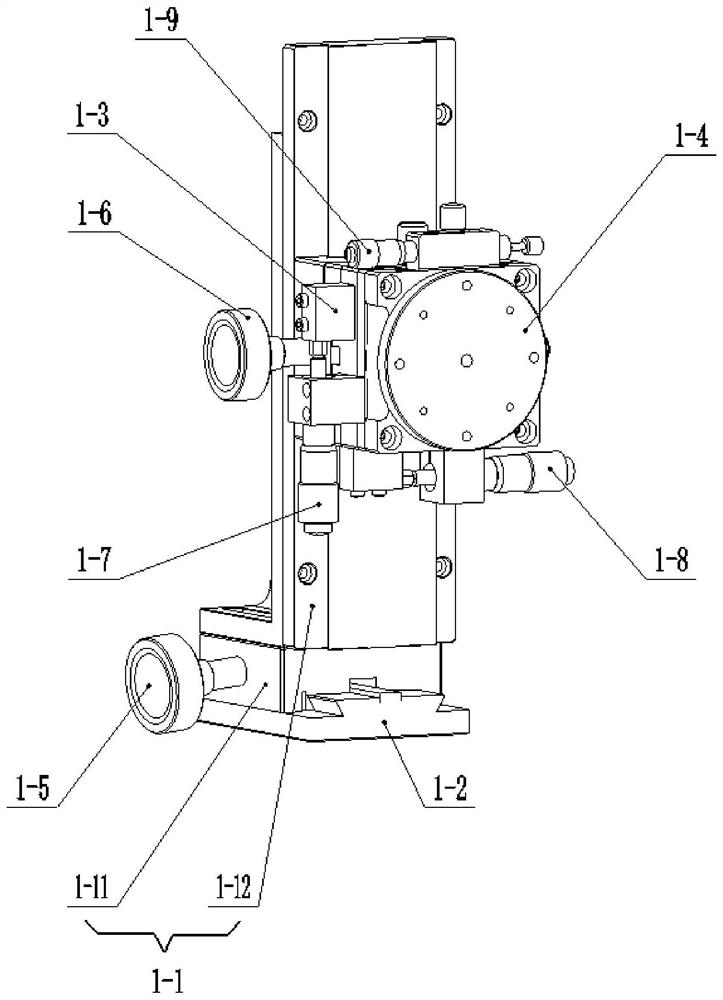

[0055] Such as figure 1 and figure 2 As shown, the present invention is a high-precision multi-dimensional adjustment and alignment system for optical fiber sensor packaging, including an optical platform 7, a wafer adsorption magazine 10, an optical fiber clamping assembly 9, a first alignment unit, a second alignment unit, Display unit 17 and spectrum monitoring unit.

[0056] The wafer adsorption material box 10 is arranged on the optical table 7, and the material of the wafer adsorption material box 10 is silica gel; the wafer adsorption material box 10 is used to place the semiconductor wafer 11 to be packaged, and the thin silica gel layer in the wafer adsorption material box 10 is opposite to the semiconductor wafer. 11 Natural adsorption and fixation, and after the optical fiber and semiconductor wafer are ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com