Straight pull type pipeline gas self-closing valve

A gas self-closing valve, straight-pull technology, applied in the direction of valve details, valve devices, functional valve types, etc., can solve the problems of endangering the life and property safety of users and the failure of self-closing valves to work, so as to ensure the safety of life and property, reduce Effects of gas leakage and less environmental disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

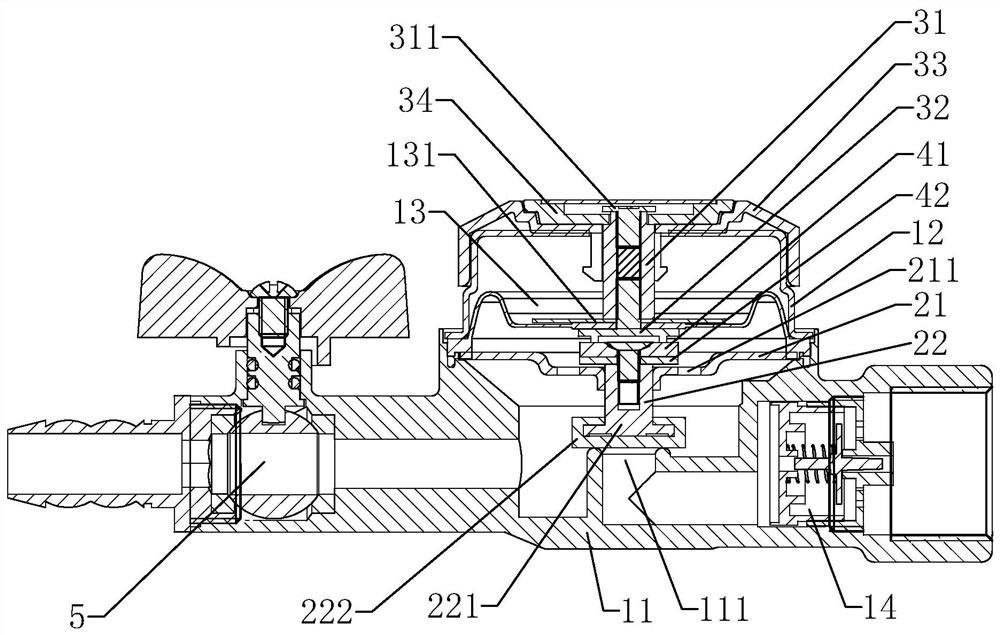

[0030] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. In the following description, a lot of specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, and those skilled in the art can do it without departing from the meaning of the present invention. By analogy, the present invention is therefore not limited to the specific examples disclosed below.

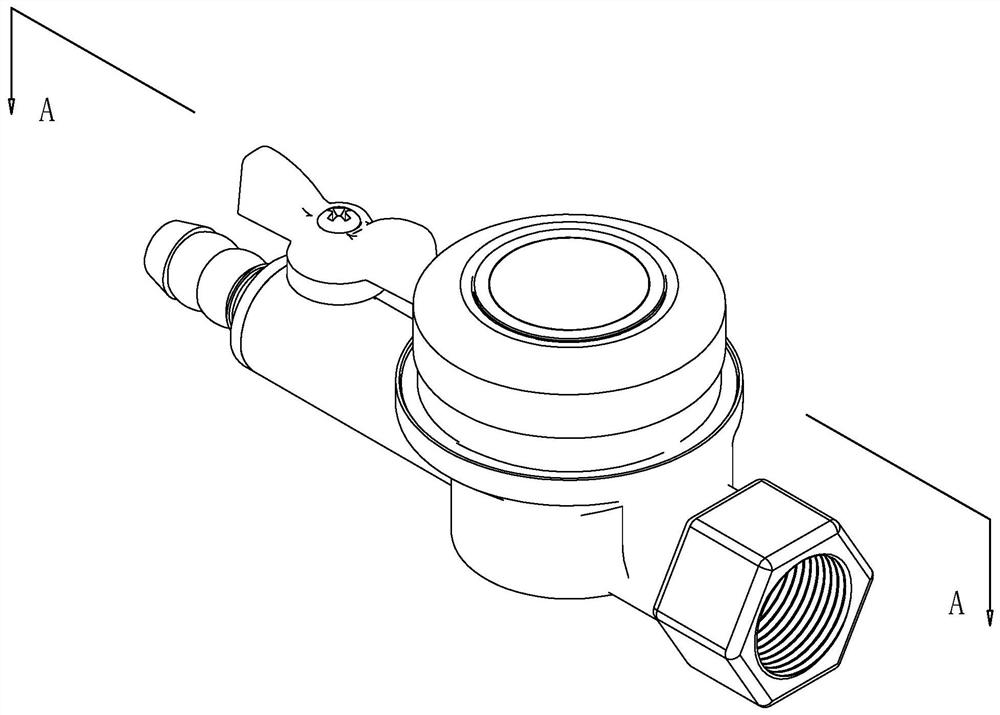

[0031] Such as figure 1 and figure 2 As shown, the self-closing valve includes a valve body 11 and a bonnet 12 assembled with the valve body 11. The two ends of the valve body 11 are respectively provided with an air inlet and an air outlet. other pipes. The top of the valve body 11 is provided with an opening for fitting with the valve cover 12. The valve cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com