Preparation method of white board containing graphene heat-conducting layer and having good ink absorbency

A graphene and ink-absorbing technology, applied in the field of whiteboard paper preparation, can solve the problems that graphene materials cannot be fully and well utilized, graphene distribution is uneven, and products are locally heated unevenly, etc., and achieve good three-dimensional thermal conductivity, Graphene is released evenly and the effect of improving release uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

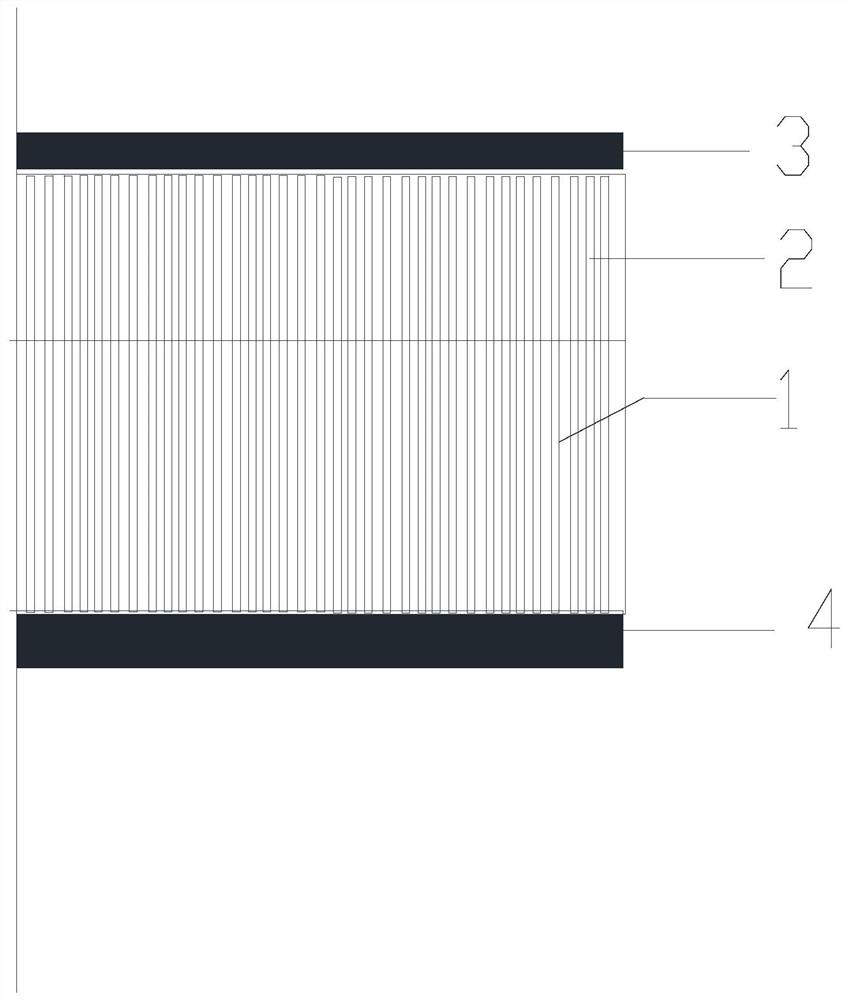

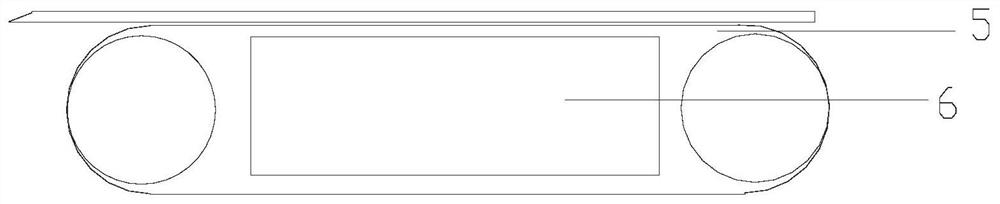

[0045] see Figure 1-2 , the present invention provides a technical solution:

[0046] The preparation method of the white board paper containing graphene heat conduction layer and good ink absorbency comprises the steps:

[0047] Step 1: Prepare graphene-infiltrated core layer paper layer 1 and graphene-infiltrated surface layer paper layer 2; specifically include the following sub-steps:

[0048] A1: configure the core layer slurry and the surface layer slurry; send the core layer slurry and the surface layer slurry into the headbox respectively to form a core layer wet paper base and a surface layer wet paper base; The wet paper base of the first layer is pre-pressed with a barbed press roll to make the moisture content 60%-65%; at the same time, after pressing, the surface of the wet paper base of the core layer and the wet paper base of the surface layer form uniformly arranged holes;

[0049] A2: graphene oxide dispersion liquid attachment: the graphene oxide dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com