Sand-stone material screening device with anti-blocking meshes for water conservancy project and automatic screening system

A technology of water conservancy projects and screening devices, which is applied in the fields of filtration and screening, solid separation, chemical instruments and methods, etc., can solve the problems of popularization of unfavorable screening devices, speed up the efficiency of sand screening, and easy clogging of mesh screens, etc., to achieve Improve the retention rate of the screen surface, improve the anti-friction performance, and improve the anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

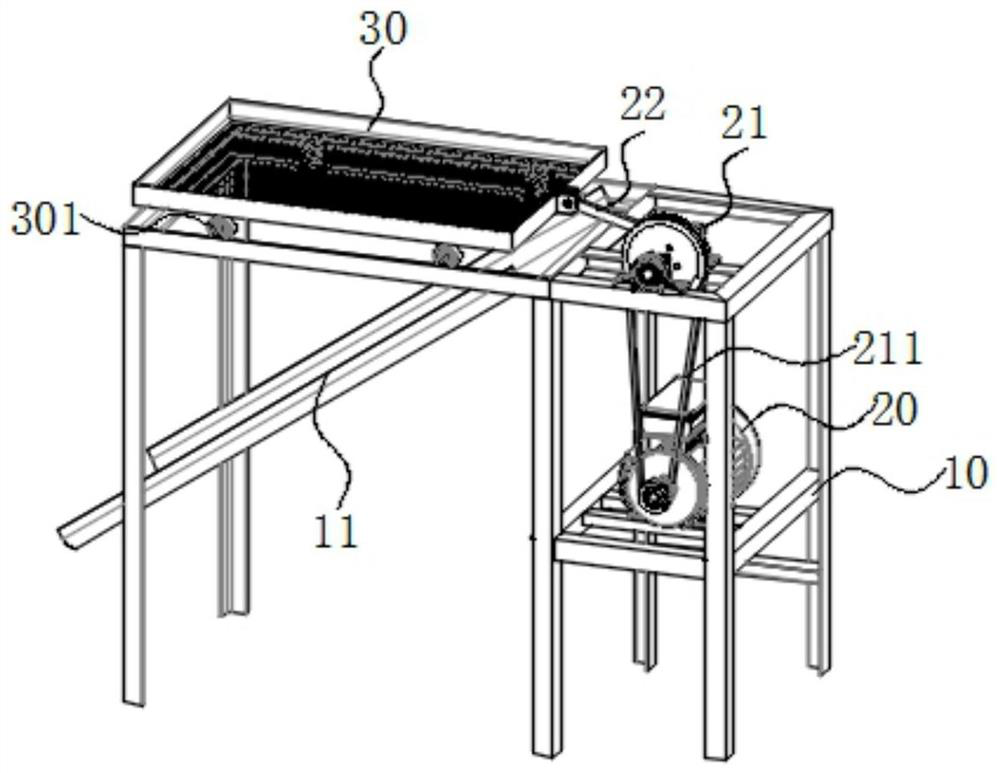

[0033] according to Figure 1-Figure 2 , Figure 7-Figure 9As shown, the anti-blocking mesh sand and gravel screening device and automatic screening system for water conservancy projects include a bracket 10, which can fix the entire screening device to ensure the stability of the screening process. The bracket 10 Drive motor 20 is installed on it, start drive motor 20, and drive motor 20 can provide driving force for the output end of drive motor 20, and the top of described support 10 is connected with control shaft 21 in rotation, between described control shaft 21 and drive motor 20 A conveyor belt 211 is installed between them, and the output end of the drive motor 20 is connected to the control shaft 21 through the transmission belt 211. Since the control shaft 21 is connected to the output end of the drive motor 20, the drive motor 20 is the control shaft 21 through the conveyor belt 211. Provide driving force to control the rotation of the control shaft 21, the contro...

Embodiment 2

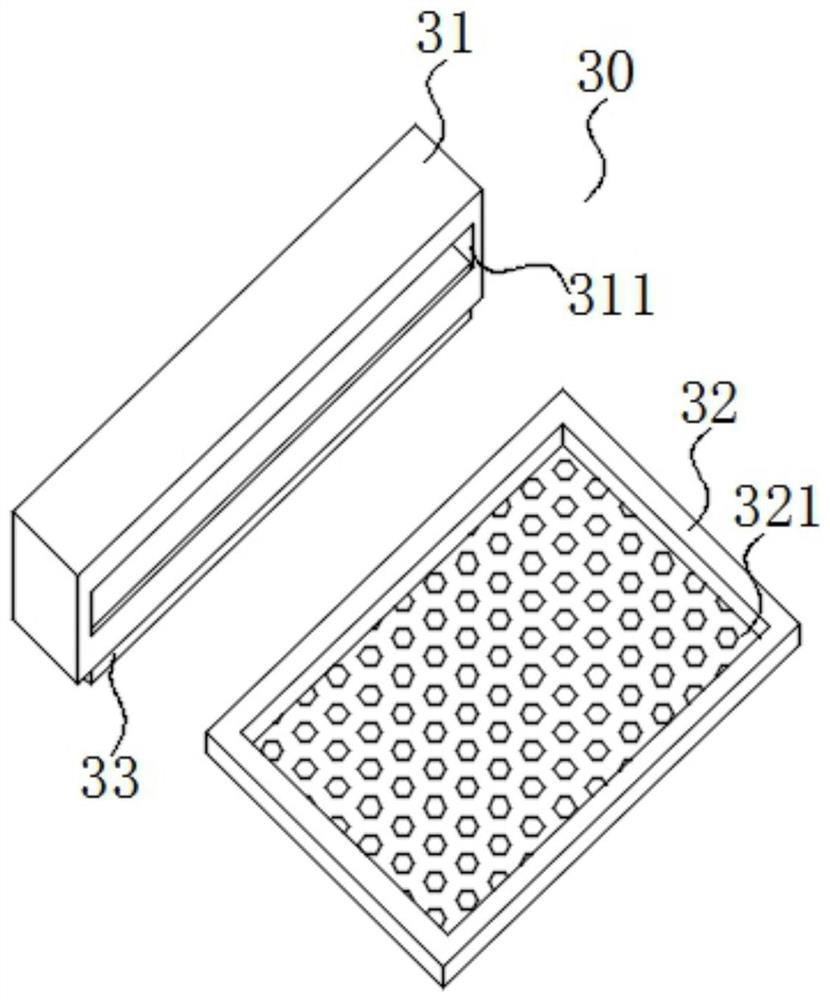

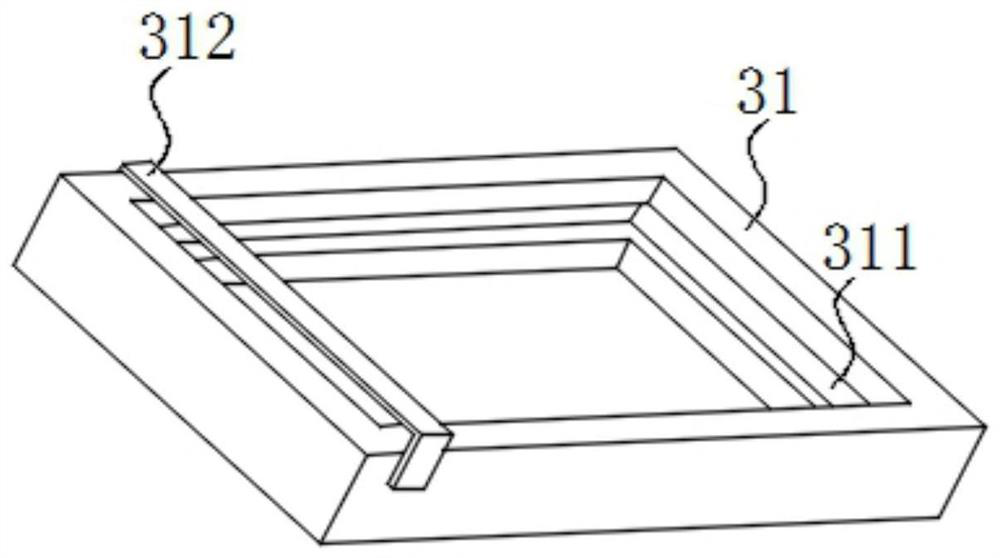

[0041] according to Figure 3-Figure 6 As shown, on the basis of Embodiment 1, the sand and gravel material screening device with anti-blocking mesh for water conservancy projects includes a sliding assembly 312, and the sliding assembly 312 utilizes the shaking force generated by the screening assembly 30 when the screening assembly 30 slides to realize Relatively sliding, so that the sliding assembly 312 can push the sand inside the screening assembly 30, the sliding assembly 312 is slidably sleeved on the outer surface of the limit frame 31, the sliding assembly 312 includes a sliding plate 3121, and the sliding plate 3121 is close to One end of the first mesh screen 32 is fixedly connected to a limit block 3122, the limit block 3122 is designed as a right triangle, and the hypotenuse on the side of the limit block 3122 close to the screening assembly 30 is parallel to the horizontal plane of the first mesh screen 32 Setting, the side of the limiting block 3122 away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com