Simple buffer tank and application thereof

A buffer tank and simple technology, applied in the field of buffer tanks, can solve the problems of increased pipeline pressure, human injury, improper operation, etc., to achieve the effect of strengthening the buffer effect, changing the buffer time, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

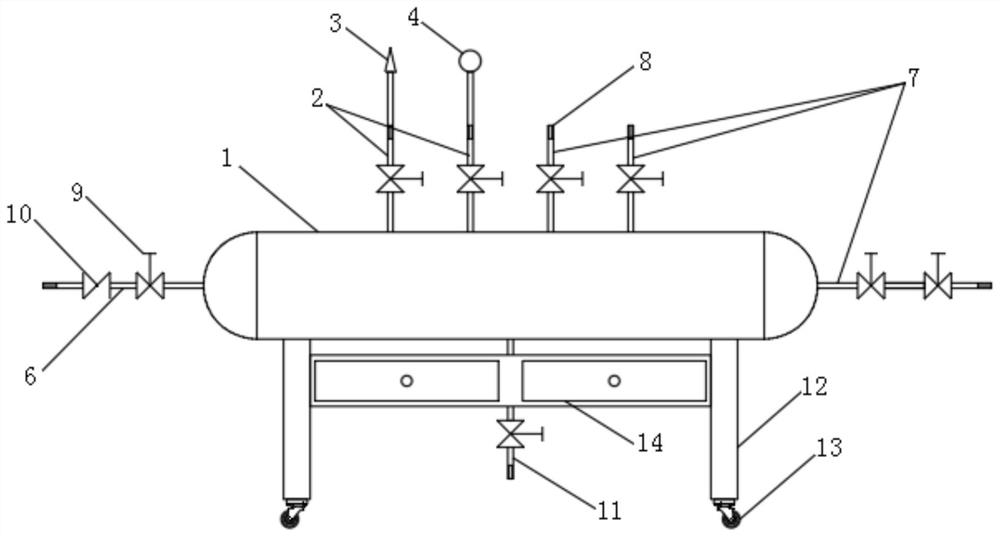

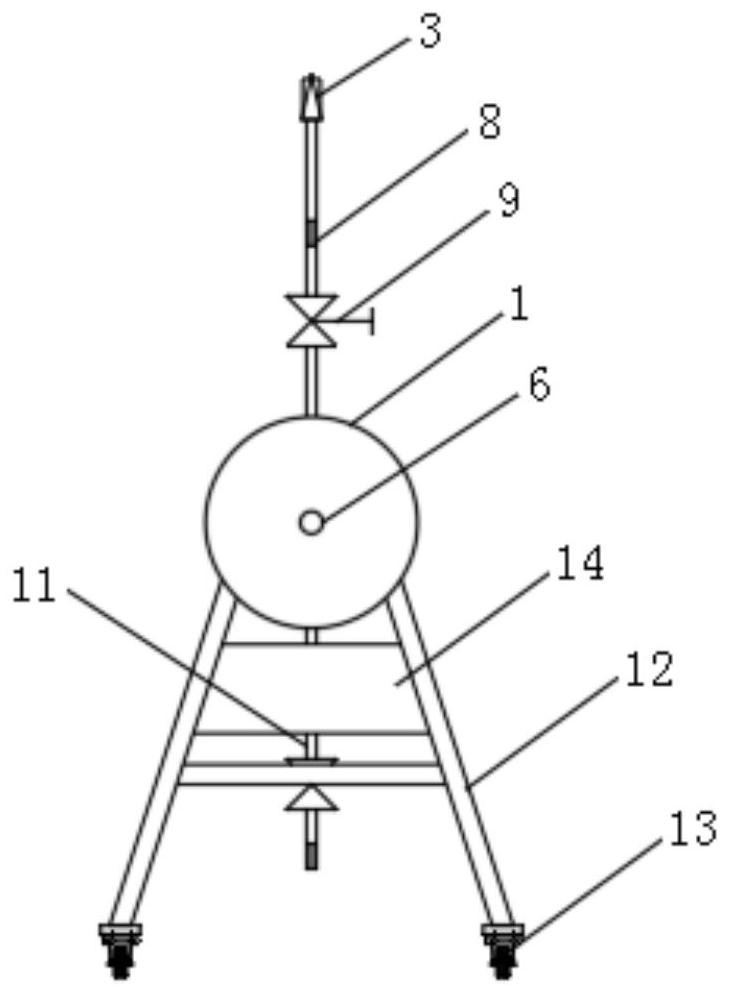

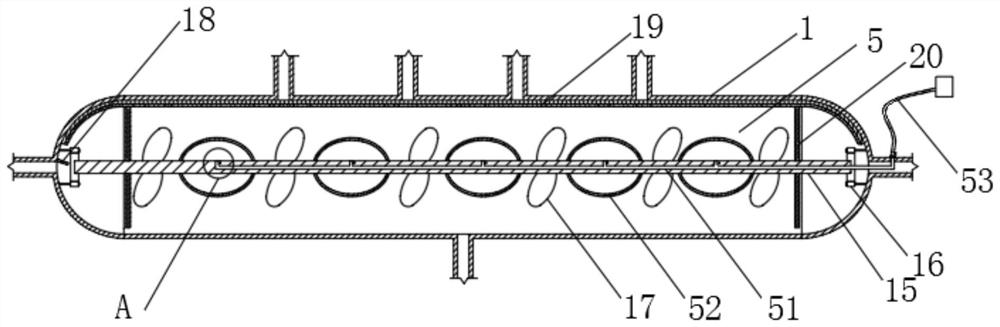

[0028] Such as Figure 1-3 As shown, a simple buffer tank includes a tank body 1, a safety valve 3 connected to the tank body 1 through a branch pipe 2, a pressure gauge 4, and a tank cavity volume adjustment assembly 5 installed in the tank body 1; The tank body 1 includes a tube body and a cap, and the caps are welded to both ends of the tube body to form a capsule-shaped tank body 1; one of the tube caps is connected to the inlet tube 6, and the other tube cap is connected to the tube 6. And the pipe body is respectively connected with one and several outlet pipes 7, the bottom of the pipe body is connected with the sewage pipe 11, and one end of the inlet pipe 6, the outlet pipe 7, the branch pipe 2, and the sewage pipe 11 is provided with a short pipe 8 connected with a wire, The branch pipe 2 is connected to the safety valve 3 and the pressure gauge 4 through a short wire connection pipe 8 at one end, and a stop valve is arranged on the branch pipe 2, the inlet pipe 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com