One-way valve structure of piston for high-voltage switch, high-speed grounding switch and GIS

A one-way valve structure, high-voltage switch technology, applied in grounding switches, high-voltage/high-current switches, electric switches, etc., can solve the problems of low reliability, complex one-way valve structure, low reliability, etc. Simple, stable movement, good use reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

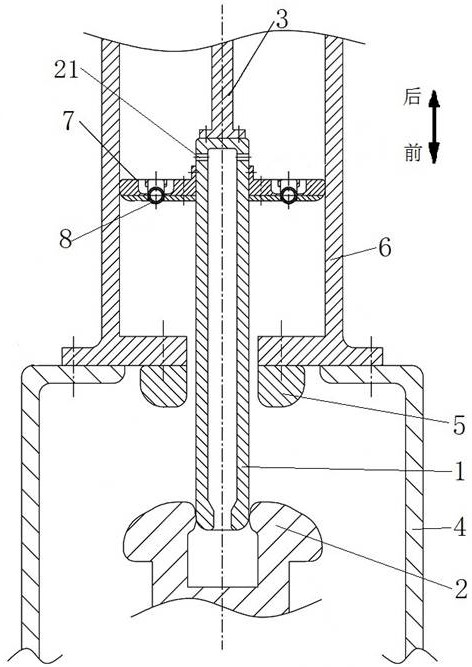

[0101] Such as figure 1 As shown, the fast grounding switch includes a cylinder 6, the arc extinguishing gas is housed in the cylinder 6, the cylinder 6 is fixedly connected to the switch housing 4, the inner chamber of the cylinder 6 communicates with the chamber in the switch housing 4, and There is a moving contact 1, and the switch housing 4 is provided with a static contact 2, the moving contact 1 is fixedly connected with the driving mechanism transmission rod 3, and the operating mechanism transmission rod 3 is used to drive the moving contact 1 and the static contact 2 Engage or disengage to realize the closing and opening actions of the fast earthing switch.

[0102] A shielding conductor 5 is also provided at the connection between the inner chamber of the cylinder 6 and the inner chamber of the switch housing 4 , and the shielding conductor 5 is used to shield the moving contact 1 at the contact position between the cylinder 6 and the switch housing 4 .

[0103] In...

Embodiment 2

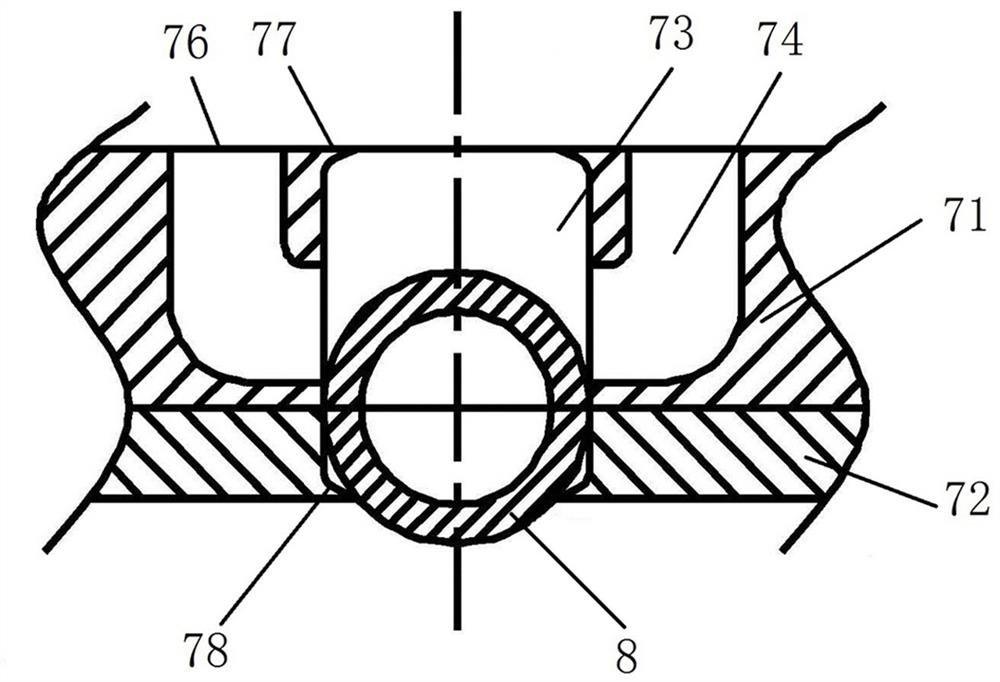

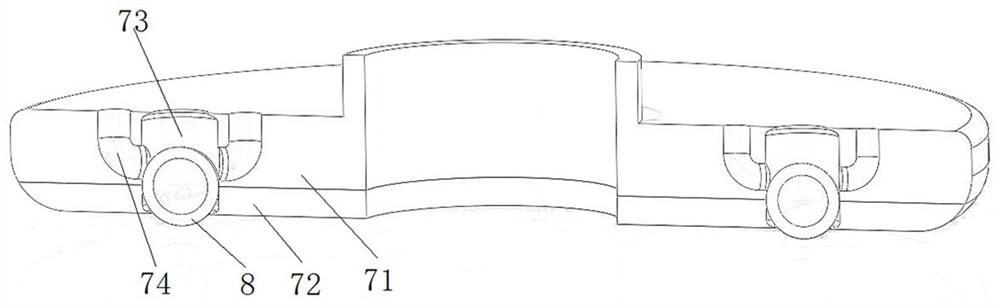

[0118] The difference between this embodiment and Embodiment 1 is that the piston in Embodiment 1 includes a rear piston body and a front piston body, a piston body for forming a one-way valve, and a rear port of the rear hole section of the rear piston body A ring of protrusions is provided at the position to form a rear limit mechanism, and a circle of protrusions is also provided at the front end opening of the front hole section of the front piston body to form a front limit mechanism to set the guiding activities at The valve ball in the guide hole is used for front and rear limit, and in this embodiment, the piston is an integral structure, the guide hole is a through hole, and the rear end of the guide hole is press-fitted with a limit ring, which is used to form a rear limit structure Cooperate with the front limit structure to limit the guide activity of the valve ball set in the guide hole.

Embodiment 3

[0120] The difference between this embodiment and Embodiment 1 is that the communication channel in Embodiment 1 is an integrated L-shaped hole, which is entirely arranged in the rear piston body, while in this embodiment, the rear piston body is adjacent to the rear hole section A vertical communication hole is provided on the ground, and a communication groove is provided on the front piston body. The notch of the communication groove faces backward and one side communicates with the front hole section of the guide hole. The communication groove is used to form a communication channel with the communication hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com