Speed regulation control device

A control device and speed regulation technology, applied in engine control, fuel injection control, fuel injection pump, etc., can solve problems affecting diesel engine performance indicators and poor control accuracy of compression springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

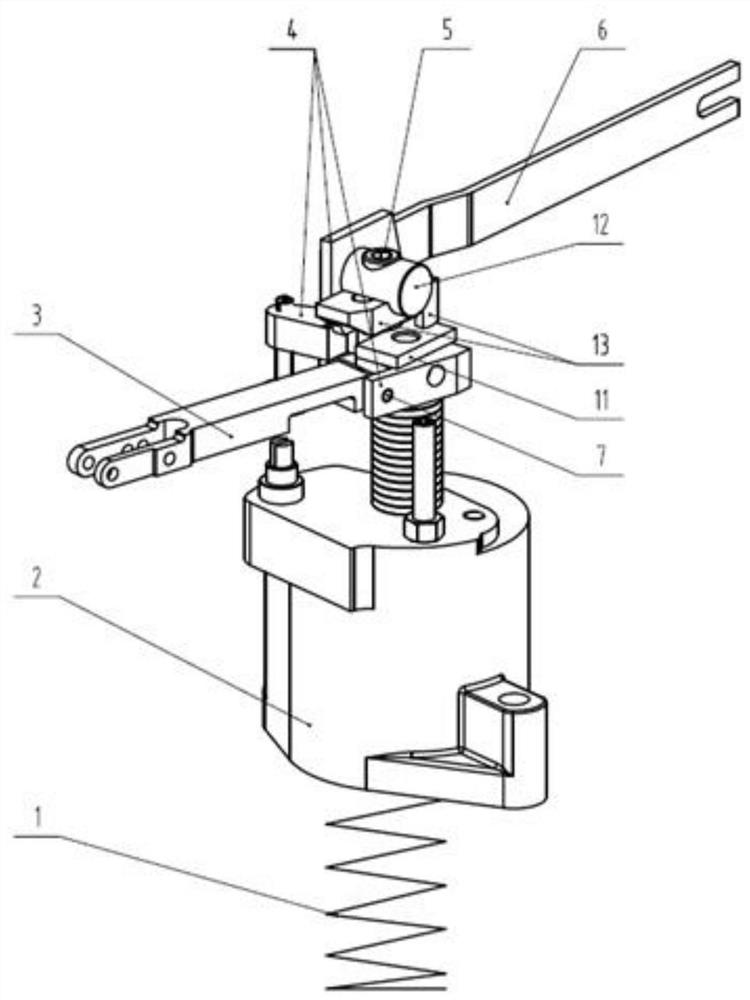

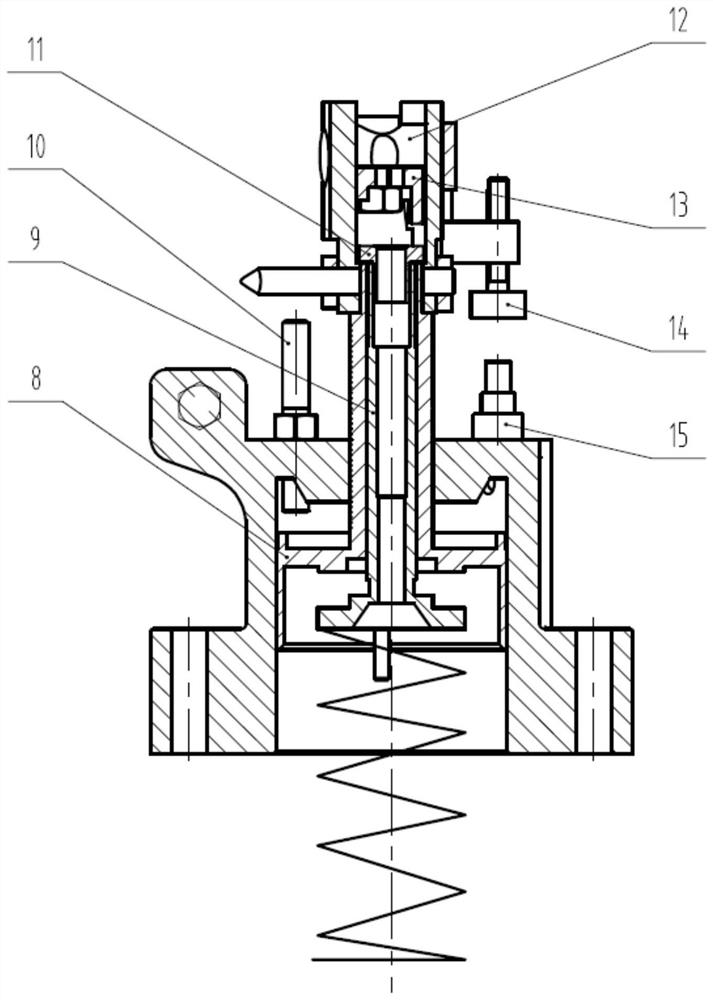

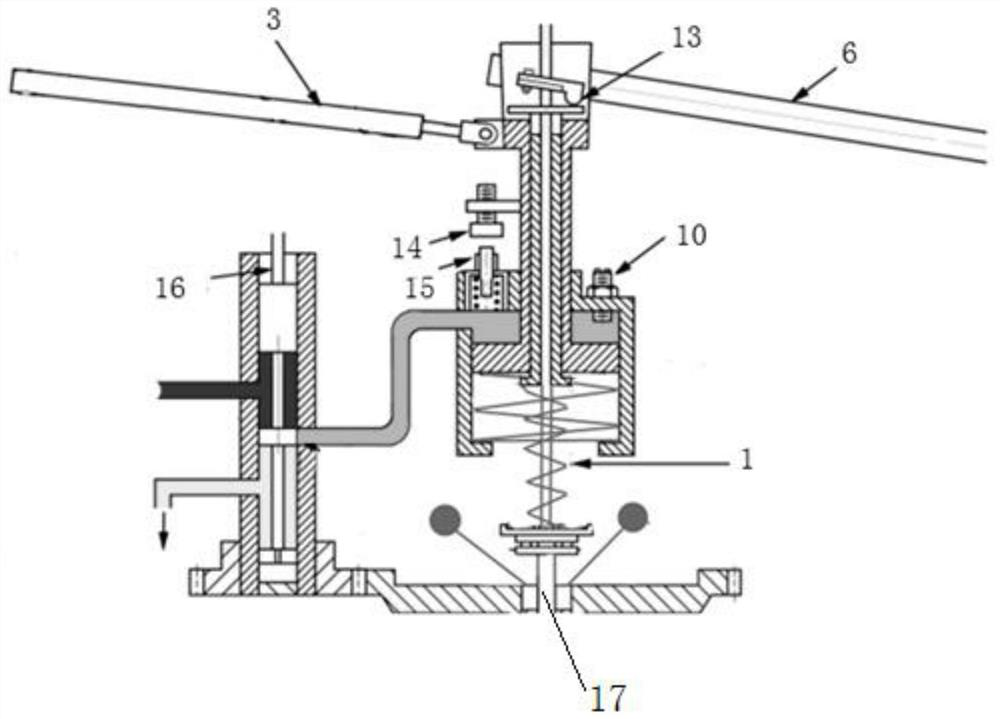

[0032] Such as figure 1 As shown, in this embodiment, a speed regulating control device includes a speed regulating spring 1, a speed regulating piston cylinder 2, a lever 3, a floating head 4, a feedback connecting rod 6, a speed regulating piston 8, a speed regulating piston rod 9, The minimum speed limit screw 10, the feedback seat 11, the first cylindrical pin 12, the feedback cam 13, the maximum speed limit screw 14 and the one-way valve 15, the specific connection relationship is as follows:

[0033] The piston portion of the speed regulating piston 8 slides with the speed regulating piston cylinder 2 and is liquid-tight, and the rod portion of the speed regulating piston 8 extends out of the speed regulating piston cylinder 2 . The speed regulating piston rod 9 is arranged coaxially with the rod portion of the speed regulating piston 8 and is fixedly connected toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com