Composite fruit wine and preparation method thereof

A technology for compounding fruit wine and mixture, which is applied to the preparation of alcoholic beverages and other directions, can solve the problems of reducing the nutritional value of lychee and longan pulp, the taste of fruit wine products is weak, and the content of flavor substances is low, so as to improve the nutritional and health care value, rich and rich aroma, The effect of low alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

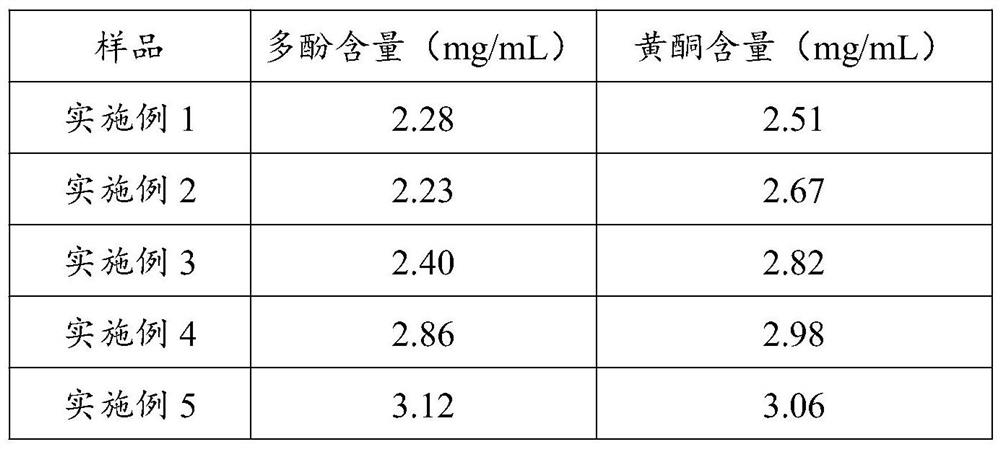

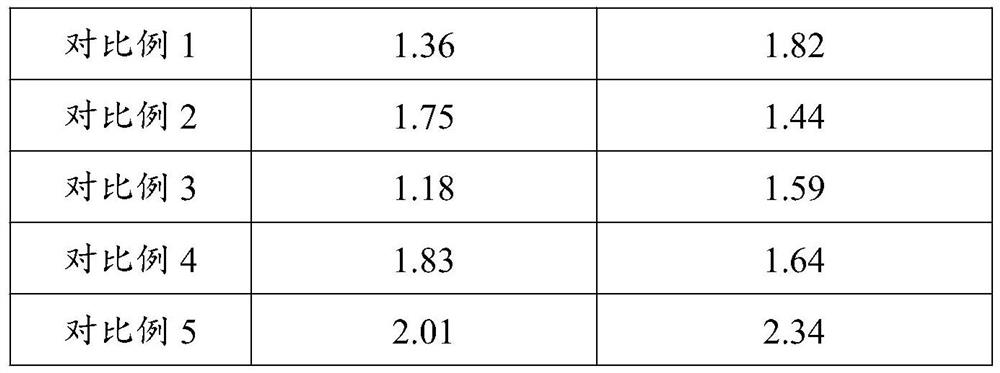

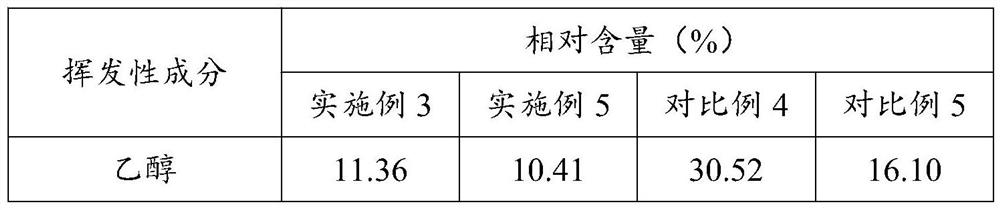

Examples

Embodiment 1

[0035] A kind of compound fruit wine is prepared by following method:

[0036] (1) After fresh lychee pulp and longan pulp are mixed in a mass ratio of 3:1, they are crushed to obtain a crushed mixture;

[0037] (2) Add 0.05% pectinase (enzyme activity: 120,000 U / g) of the mass of the crushed mixture to the crushed mixture described in step (1), and perform enzymatic hydrolysis for 2 hours at pH = 3.0 and a temperature of 50°C , to obtain the enzymatic hydrolysis mixture;

[0038] (3) adding 0.14% white granulated sugar of enzymolysis mixture mass and 0.01% enzymolysis mixture mass potassium metabisulfite to the enzymolysis mixture described in step (2), and mixing at 30° C. for 3 hours to obtain a mixed product;

[0039] (4) in the mixed product described in step (3), add the 0.1% mixed product quality Klerkia citriformis, add CO 2 In a gas fermenter, ferment for 5 days at 22°C to obtain the first fermentation liquid of litchi and longan pulp; add 0.08% active dry yeast wit...

Embodiment 2

[0043] A kind of compound fruit wine is prepared by following method:

[0044] (1) After fresh lychee pulp and longan pulp are mixed in a mass ratio of 5:1, they are crushed to obtain a crushed mixture;

[0045] (2) Add 0.1% pectinase (enzyme activity: 100,000 U / g) of the mass of the crushed mixture to the crushed mixture described in step (1), and perform enzymatic hydrolysis for 3 hours at pH = 4.0 and a temperature of 45°C , to obtain the enzymatic hydrolysis mixture;

[0046] (3) adding 0.20% white granulated sugar of enzymolysis mixture mass and 0.02% enzymolysis mixture mass potassium metabisulfite to the enzymolysis mixture described in step (2), and mixing at 25° C. for 4 hours to obtain a mixed product;

[0047] (4) in the mixed product described in step (3), add the 0.5% mixed product quality Klerkia citriformis, add CO 2 In a gas fermenter, ferment for 3 days at 25°C to obtain the first fermentation liquid of litchi and longan pulp; add 0.1% active dry yeast with ...

Embodiment 3

[0051] A kind of compound fruit wine is prepared by following method:

[0052] (1) After fresh lychee pulp and longan pulp are mixed in a mass ratio of 6:1, they are crushed to obtain a crushed mixture;

[0053] (2) Add 0.2% pectinase (enzyme activity: 150,000 U / g) of the mass of the crushed mixture to the crushed mixture described in step (1), and perform enzymatic hydrolysis for 4 hours at pH = 3.6 and a temperature of 40°C , to obtain the enzymatic hydrolysis mixture;

[0054] (3) adding 0.10% white granulated sugar of enzymolysis mixture mass and 0.03% enzymolysis mixture mass potassium metabisulfite to the enzymolysis mixture described in step (2), and mixing at 35° C. for 2 hours to obtain a mixed product;

[0055] (4) in the mixed product described in step (3), add the Klerkia citrate yeast of 0.4% mixed product quality, add CO 2 In a gas fermenter, ferment for 6 days at 20°C to obtain the first fermentation liquid of litchi and longan pulp; add 0.3% active dry yeast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com