Garlic cold storage warehouse-in and warehouse-out quantity monitoring system

A monitoring system, garlic technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problem of inaccurate quantity monitoring, and achieve the effect of accurate quantity monitoring, convenient use, and reduced workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

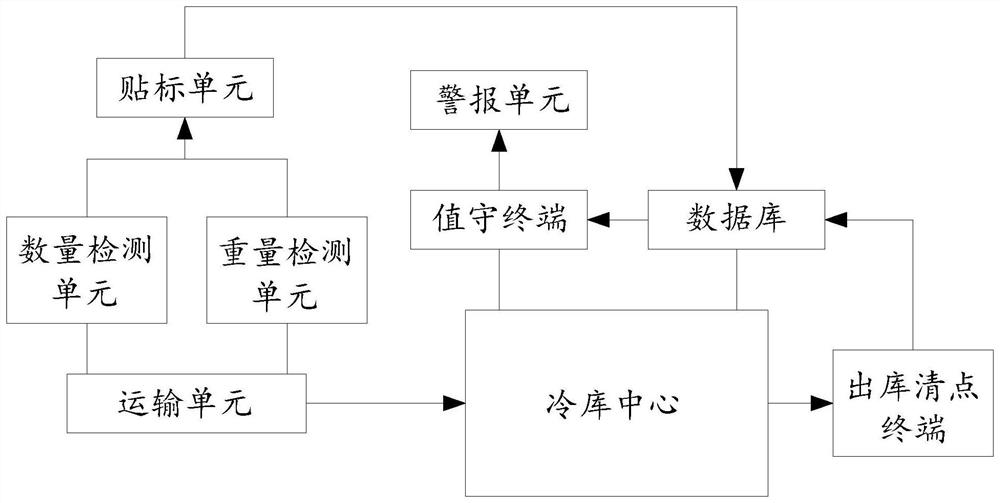

[0041] The monitoring system for the number of garlic cold storage in and out of the warehouse according to the present invention includes a transport unit, a cold storage center and a warehouse-out checking terminal, the cold storage center includes a database and a terminal on duty, and the terminal on duty includes an alarm unit;

[0042] The transportation unit transports the garlic packed in standard woven bags to the cold storage center for storage, and uploads the storage information to the database at the same time, which is convenient for cold storage management personnel and customers to check and check;

[0043] The outbound inventory terminal confirms the quantity of garlic to be outbound, and after confirming the quantity of garlic to be outbound, uploads the outbound information to the database, and the database updates the garlic inventory information in the cold storage center in real time, and simultaneously sends the outbound information to to the on-duty term...

Embodiment 2

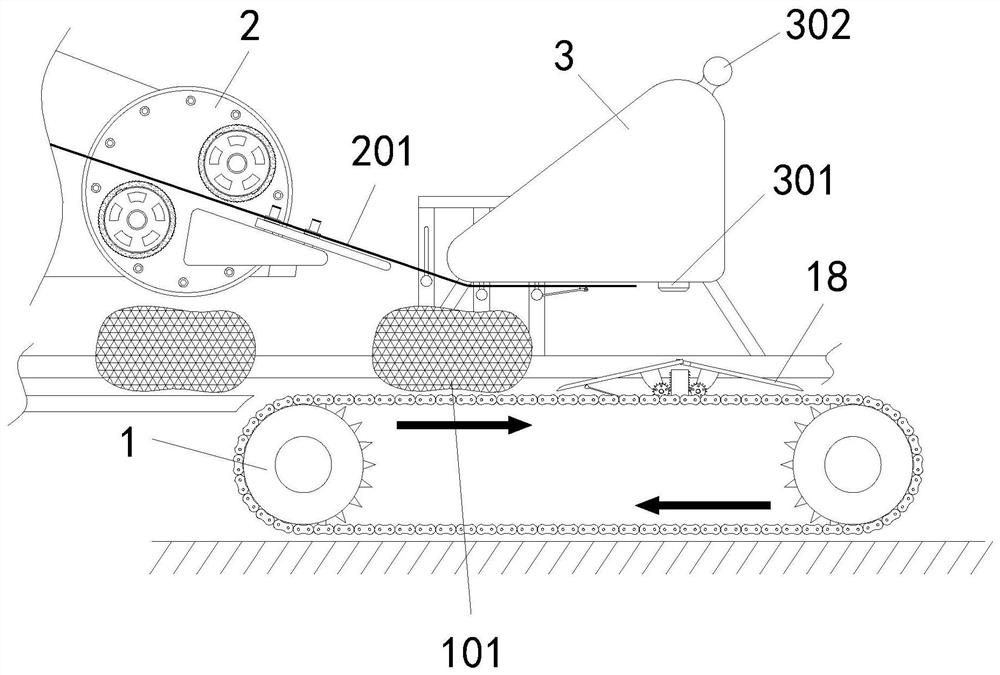

[0054] Such as Figure 10 As shown in Comparative Example 1, another embodiment of the present invention is: the bottom end of the pressure head 7 is movably inserted with an auxiliary pressure plate 16, the auxiliary pressure plate 16 is inclined, and a reset puller is installed on the auxiliary pressure plate 16. Spring, when working, under the initial state, the auxiliary pressure plate 16 shrinks in the pressure head 7, when the pressure head 7 and the label 201 are attached to the bag body 101 and rotated, the auxiliary pressure plate 16 protrudes outward under the action of centrifugal force , and press on the label 201, the smoothing range of the label 201 can be improved, and the bonding effect of the label 201 can be further improved.

[0055] working principle:

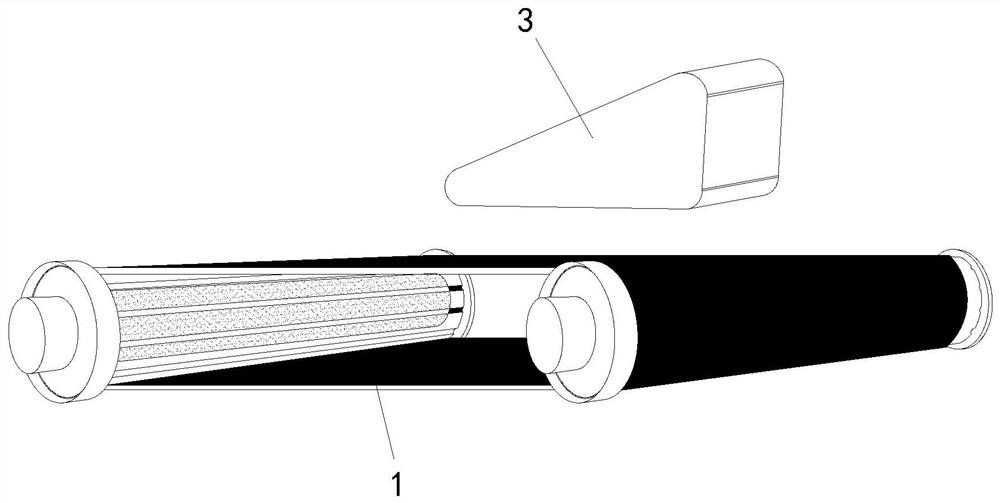

[0056] The bags 101 move on the transmission mechanism 1, count the number of bags 101 through the counting unit, and the information after the detection of the bags 101 is printed out through the label 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com