Drilling automatic dust falling device capable of fixing mobile phone mainboard

A technology for fixing mobile phones and dust suppression devices, which is applied in metal processing, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of mobile phone motherboards not being fixed, debris requiring manual collection, etc., to reduce labor intensity and ensure normal operation work, the effect of ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

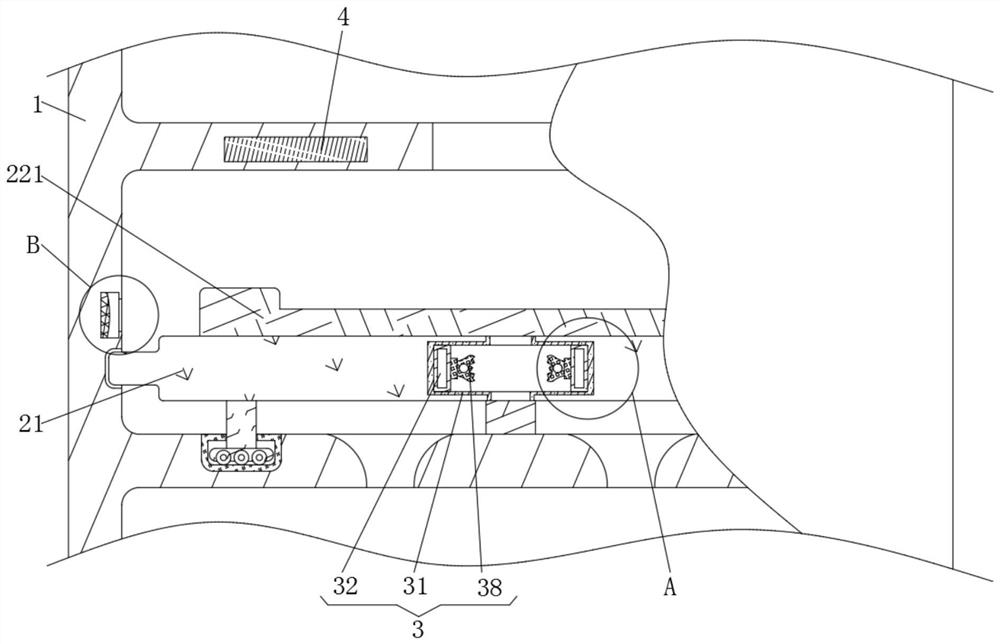

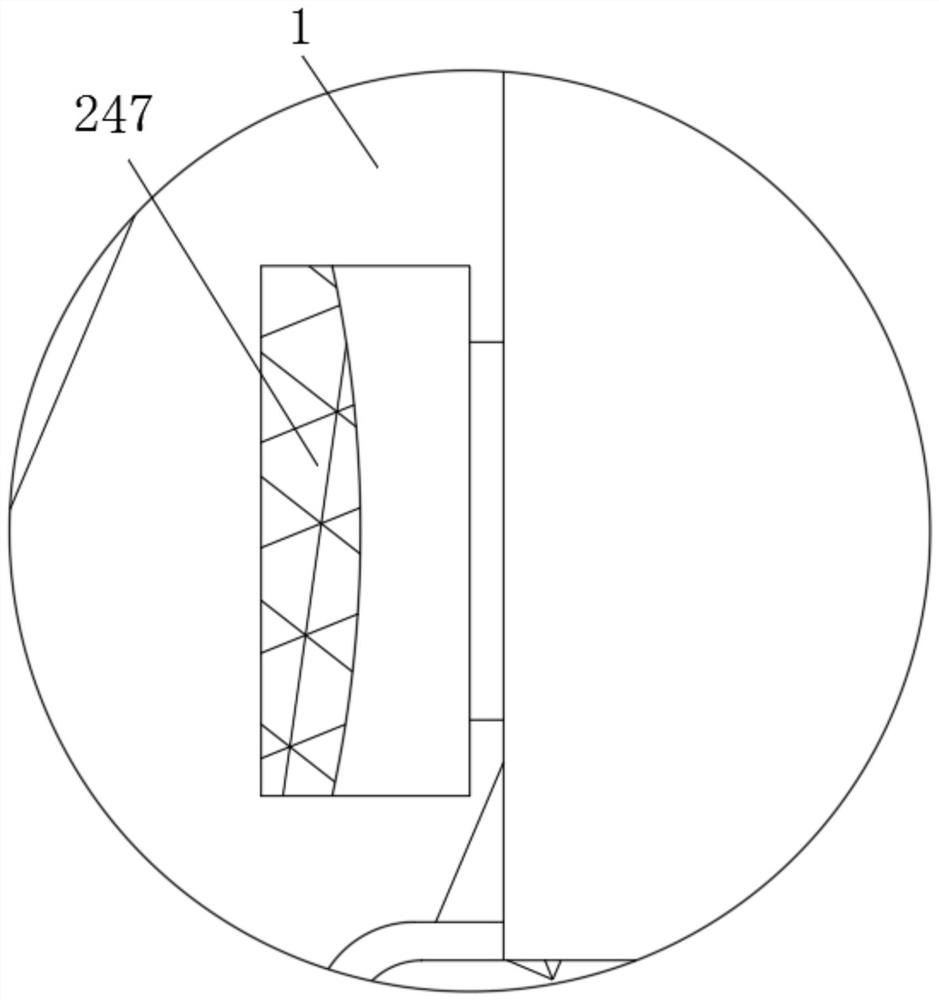

[0031] see figure 1 , 3 , 4, 5, 6, a drilling automatic dust suppression device capable of fixing the main board of the mobile phone, including a casing 1, the inside of the casing 1 is movably connected with a fixed engagement mechanism 2, and the fixed engagement mechanism 2 includes a support plate 21 and a fixed assembly 22 , an engaging component 23 , a limiting component 24 , and a fixing component 22 is movably connected to the inside of the support plate 21 .

[0032] The fixed assembly 22 includes a fixed plate 221, a support plate 222, a cylinder 223, a push rod 224, a support block 225, and a push assembly 226. The fixed plate 221 is fixedly connected to the outside of the support plate 21, and the support plate 222 is fixedly connected to the outside of the support plate 21. , the cylinder 223 is fixedly connected to the inside of the fixed plate 221 , the push rod 224 is slidably connected to the outside of the cylinder 223 , and the support block 225 is fixedly ...

Embodiment 2

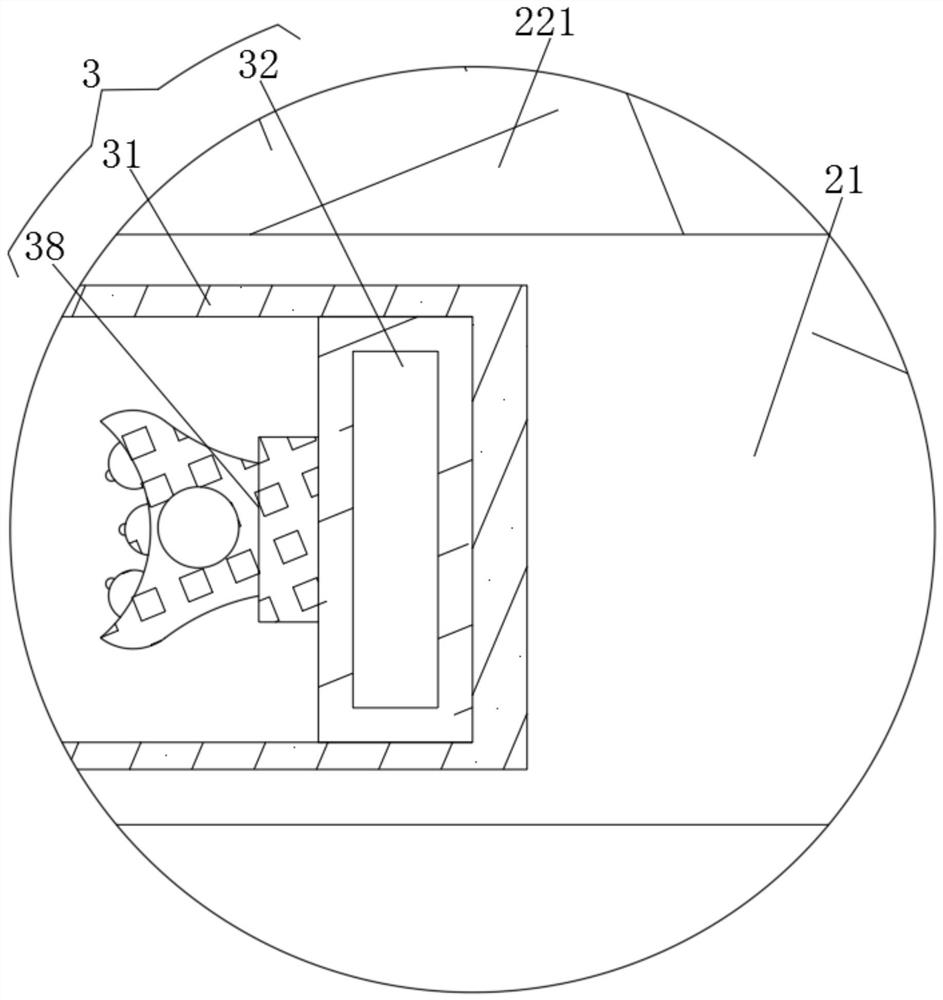

[0037] see figure 1 , 2 7. A drilling automatic dust suppression device capable of fixing the mainboard of the mobile phone, comprising a casing 1, the inside of the casing 1 is movably connected with a fixed engagement mechanism 2 capable of fixing the mainboard of the mobile phone, and the fixed engagement mechanism 2 includes a support plate 21, The inside of the support plate 21 is movably connected with a dust-reducing mechanism 3, and the dust-reducing mechanism 3 includes a concave shell 31, a valve cover 32, a fixed block 33, an electromagnet 2 34, a movable block 35, a telescopic spring 36, an iron block 37, a nozzle 38, and a concave shell 31 is fixedly connected to the inside of the support plate 21, the valve cover 32 is fixedly connected to the inside of the concave shell 31, the fixed block 33 is fixedly connected to the inside of the concave shell 31, the electromagnet 2 34 is fixedly connected to the inside of the fixed block 33, and the movable block 35 Slidi...

Embodiment 3

[0039] see Figure 1-7 , a drilling automatic dust suppression device capable of fixing the mainboard of a mobile phone, comprising a casing 1, the interior of the casing 1 is movably connected with a fixed engaging mechanism 2, and the fixed engaging mechanism 2 includes a support plate 21, a fixed assembly 22, an engaging assembly 23, The limiting component 24 is movably connected with the fixing component 22 inside the support plate 21 .

[0040] The fixed assembly 22 includes a fixed plate 221, a support plate 222, a cylinder 223, a push rod 224, a support block 225, and a push assembly 226. The fixed plate 221 is fixedly connected to the outside of the support plate 21, and the support plate 222 is fixedly connected to the outside of the support plate 21. , the cylinder 223 is fixedly connected to the inside of the fixed plate 221 , the push rod 224 is slidably connected to the outside of the cylinder 223 , and the support block 225 is fixedly connected to the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com