Processing equipment and preparation method of weathering steel welding rod

A technology for processing equipment and weathering steel, applied in metal processing equipment, welding equipment, welding media, etc., can solve the problems of reducing the use and storage time of materials, inconvenient loading and unloading of drug skins, and inconvenient welding rod production, etc., to improve the convenience. , easy to reset again, improve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

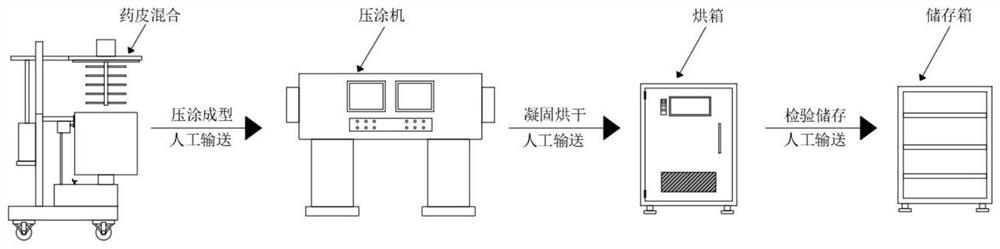

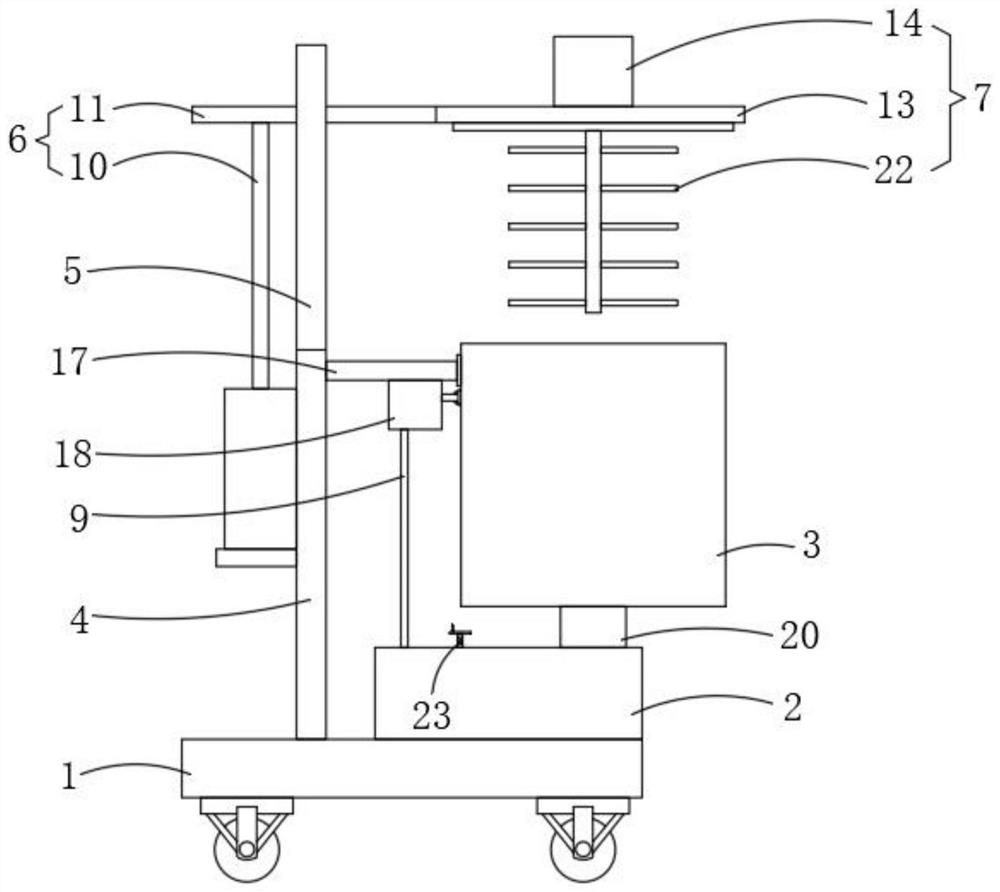

[0034] see Figure 1-6 , the present invention provides a technical solution: a processing equipment for weather-resistant steel electrodes, including coating mixing equipment, a press coater, an oven and a storage box, the coating mixing equipment includes a base 1, and one side of the top of the base 1 is fixedly installed with Box 2, a mixing box 3 is installed on one side of the top of the box 2, and a pillar 20 is fixedly installed at the center of the bottom of the mixing box 3. The top of the pillar 20 slides through the box body 2 and extends to the inner cavity of the box body 2 and The inner wall of the box body 2 is rotatably connected, and the surface of the box body 2 is provided with a moving groove 21 adapted to the pillar 20. The pillar 20 slides through the box body 2 through the moving groove 21. By setting the moving groove 21, the mixing box 3 is tilted. At the same time, the prop 20 is driven to rotate, and the prop 20 rotates in the moving groove 21 witho...

Embodiment 2

[0041] see Figure 1-6 , the difference between this embodiment 2 and embodiment 1 is:

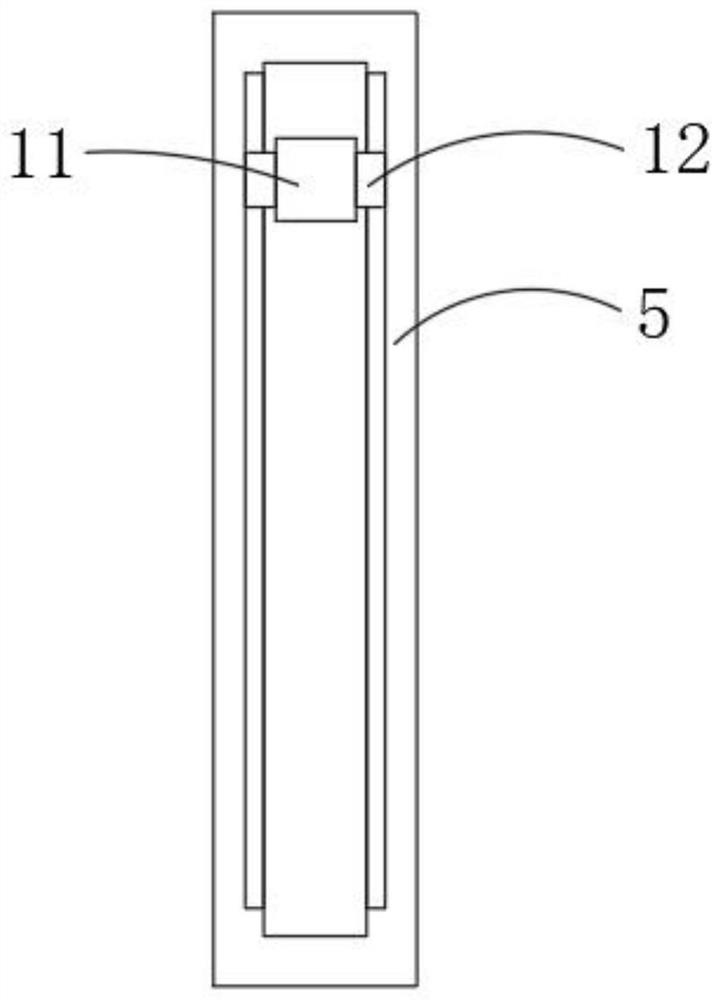

[0042] The step-type lifting adjustment mechanism 6 includes a step-type lift cylinder 10, one side of the step-type lift cylinder 10 is bolted to the top of the strut 4 away from the side of the mixing box 3, and the telescopic end of the step-type lift cylinder 10 is fixedly installed There is a lifting slide bar 11, and one end of the lifting slide bar 11 slides through the limit frame 5 and extends to the outside of the limit frame 5 and is welded to one side of the mixing and stirring mechanism 7; by setting a step-by-step lifting adjustment mechanism 6, it is used for The height of the mixing and stirring mechanism 7 is adjusted so that it will not hinder the unloading and loading work; Move in the position frame 5, the lifting slider 11 drives the cover plate 13 to move, the cover plate 13 drives the first drive motor 14 and the stirring shaft 22 to move, the stirring shaft 22 is i...

Embodiment 3

[0052] Such as figure 1 , on the basis of embodiment 1 and embodiment 2, this embodiment also provides a kind of preparation method of weathering steel welding rod, and concrete steps are as follows:

[0053] S1: Determine the formula, purchase the corresponding raw materials and meet the required process requirements according to the requirements of the formula;

[0054] S2: Drug skin processing, crushing, grinding, and sieving the raw materials of the drug skin, and making a reasonable ratio according to the formula requirements;

[0055] S3: welding core processing, the process of derusting, drawing and direct nuclear cutting is performed on the welding core in order to meet the formula requirements;

[0056] S4: Preparation and blending of water glass. According to the formula requirements, a certain concentration of water glass is blended with the drug skin in subsequent processing, used as a binder, and accelerates the solidification of the drug skin;

[0057] S5: Stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com