Full-fraction catalytic gasoline selective hydrodesulfurization device

A technology for catalytic gasoline and hydrodesulfurization, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problem of inability to classify and desulfurize gasoline raw materials, save time for classification selection, avoid waste, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

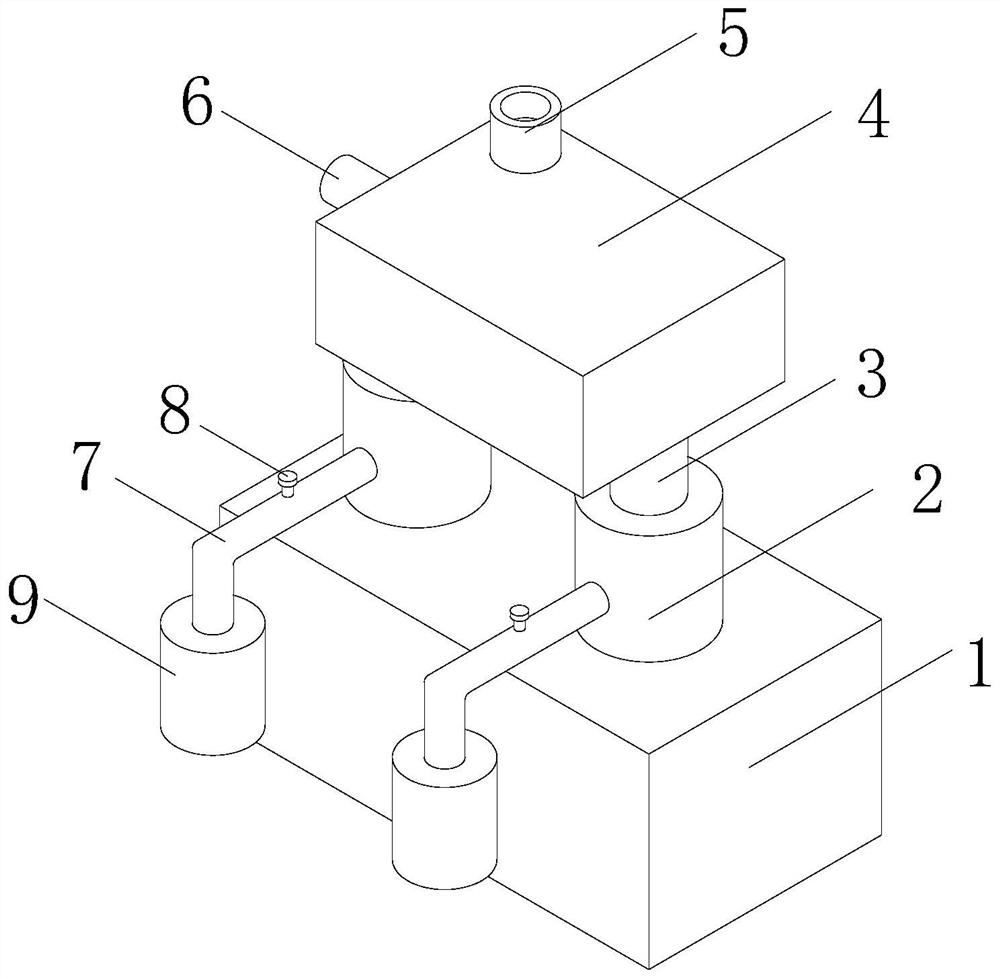

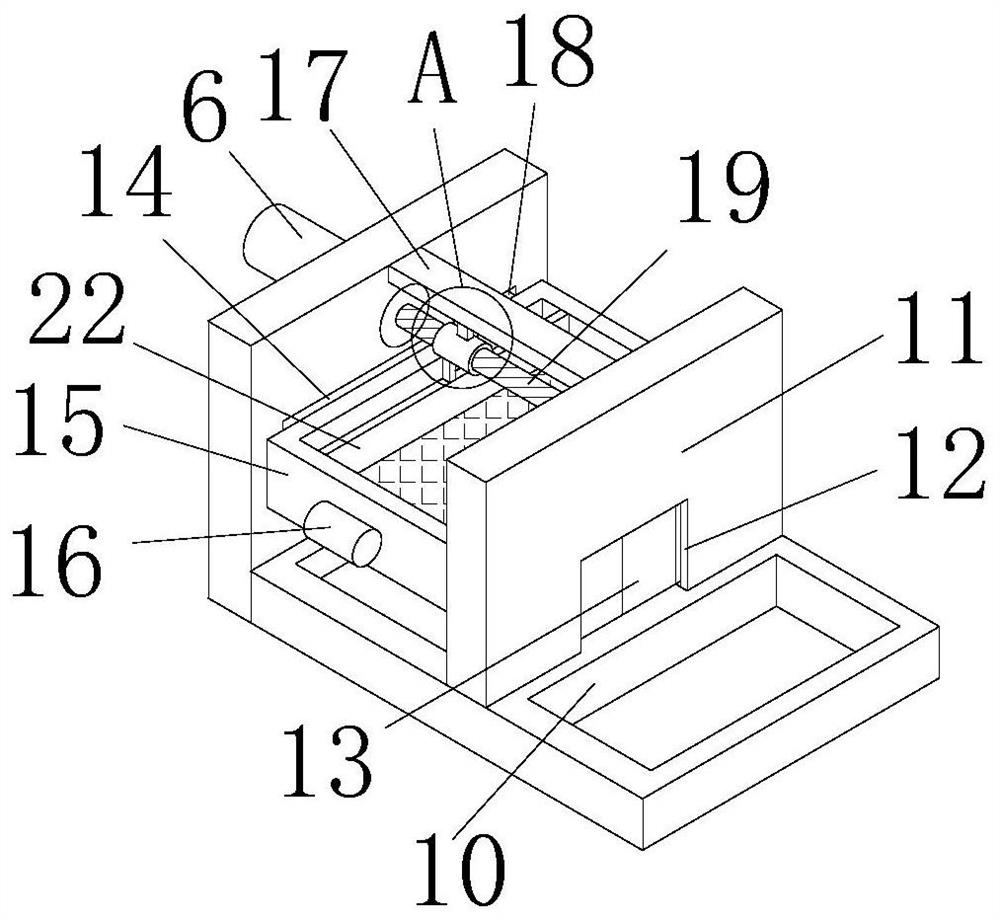

[0034] see Figure 1-6 , the present invention provides a technical solution: a full-fraction catalytic gasoline selective hydrodesulfurization device, including a base 1, the left and right sides of the top surface of the base 1 are fixedly connected with desulfurizers 2, and the top surfaces of the two desulfurizers 2 Both are fixedly connected with a connecting pipe 3, and the two connecting pipes 3 communicate with the interior of the two desulfurizers 2 respectively. The internal connection of the classification box 4 is fixedly connected with the feed pipe 5, and the left side of the classification box 4 is fixedly connected with the motor 6. The motor 6 and the desulfurizer 2 are all existing structures, and will not be described too much here. The front surfaces of the two desulfurizers 2 are fixedly connected with a discharge pipe 7, and the two discharge pipes 7 are provided with a valve 8, and the lower ends of the two discharge pipes 7 are fixedly connected with a ...

Embodiment 2

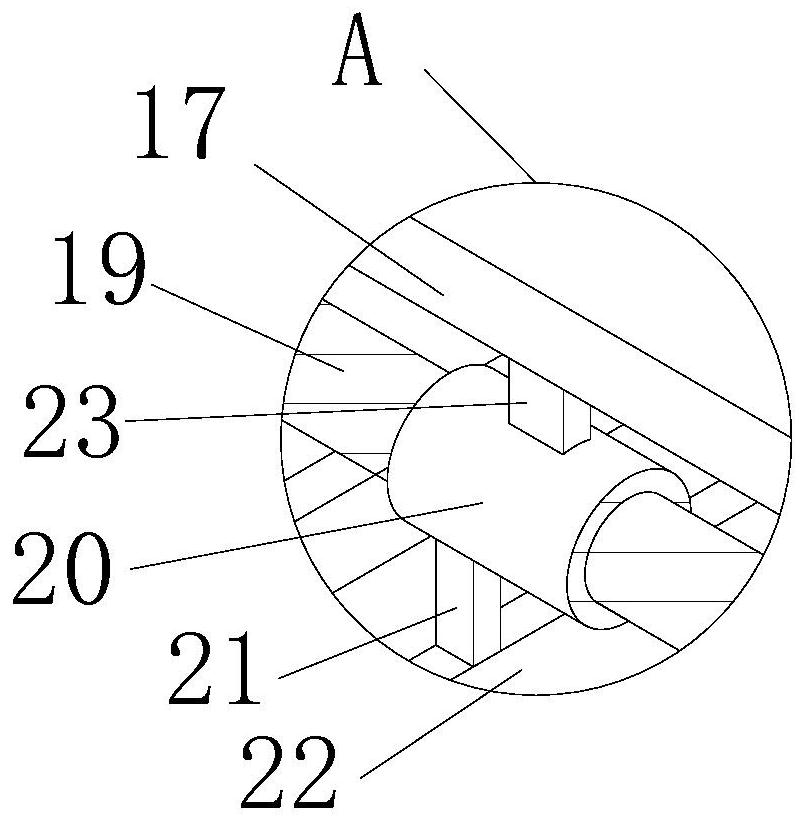

[0040] see Figure 1-6 , on the basis of embodiment one, the inside of sorting box 4 is provided with feeding device, and feeding device comprises threaded rod 19 and track 17, and threaded rod 19 is connected in rotation on the left surface of sorting case 4 inside, and threaded rod 19 and baffle plate 11 rotating connection, the left end of threaded rod 19 runs through the output end of sorting box 4 and motor 6 and is fixedly connected, and track 17 is fixedly connected on the left surface inside sorting box 4, and track 17 is positioned at the top surface of threaded rod 19 and is not connected with threaded rod 19 contacts, the rail 17 is fixedly connected with the baffle plate 11, the threaded sleeve 20 is threaded on the threaded rod 19, the top surface of the threaded sleeve 20 is fixedly connected with a connecting rod 23, and the upper end of the connecting rod 23 is slidably connected to the inside of the track 17. The bottom surface of the cover 20 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com