Fish scale mucus removing equipment and use method thereof

A technology of fish scales and mucus, which is applied in the direction of fish cleaning / descaling, etc., can solve the problems of rot, inability to quickly and effectively remove fish scale mucus, fish scale smell, etc., and achieve the effect of preventing damage, reducing metal fatigue, and avoiding adhesion to the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

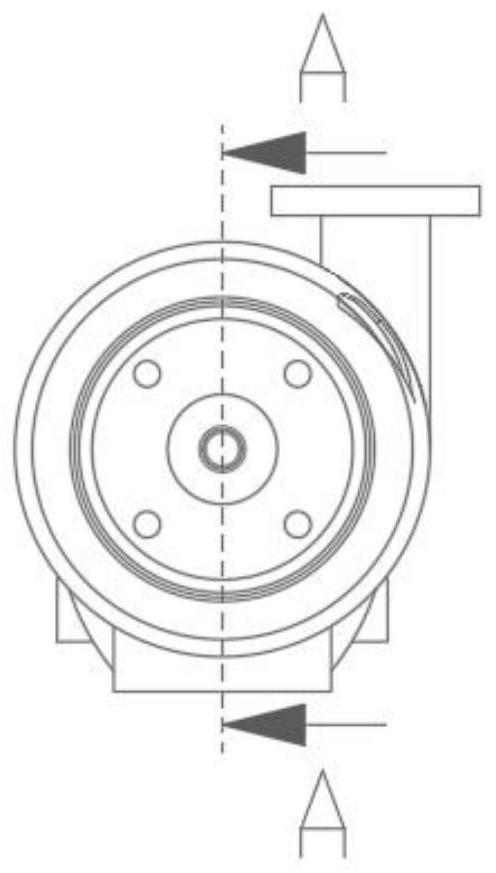

[0043] Such as Figure 1-6 As shown, the equipment for removing mucus from fish scales includes a descaling mechanism, a mucus removing mechanism, and a frame 2. The mucus removing mechanism is arranged at the lower end of the descaling mechanism, and the descaling mechanism 1 is arranged on the frame 2;

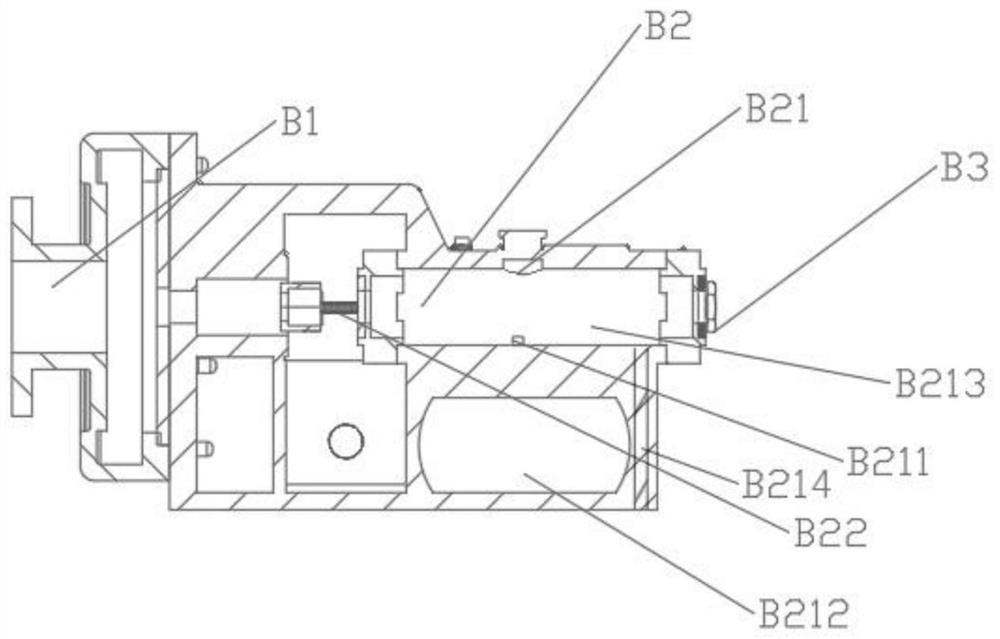

[0044] The slime removal mechanism includes a feed chamber B1, a liquid removal chamber B2, and a discharge chamber B3. The tail end of the feed chamber B1B2 is conductively connected with the liquid removal chamber B2, and the tail end of the liquid removal chamber B2 is conductively connected with the discharge chamber B3.

[0045] The liquid removal chamber B2 includes a cooling mechanism B21, a rolling mechanism B22, and a liquid outlet channel B214. The cooling mechanism B21 is located on the right side of the rolling mechanism B22. The cooling mechanism B21 includes a cooling nozzle B211, a cooling liquid tank B212, a cooling reaction zone B213, and a cooling liquid tan...

Embodiment 2

[0048] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, the equipment for removing mucus from fish scales includes a descaling mechanism, a mucus removing mechanism, and a frame 2. The mucus removing mechanism is arranged at the lower end of the descaling mechanism, and the descaling mechanism 1 is arranged on the frame 2;

[0049] The slime removal mechanism includes a feed chamber B1, a liquid removal chamber B2, and a discharge chamber B3. The tail end of the feed chamber B1B2 is conductively connected with the liquid removal chamber B2, and the tail end of the liquid removal chamber B2 is conductively connected with the discharge chamber B3.

[0050] The liquid removal chamber B2 includes a cooling mechanism B21 and a rolling mechanism B22. The cooling mechanism B21 is located on the right side of the rolling mechanism B22. The cooling mechanism B21 includes a cooling nozzle B211, a cooling liquid tank B212, and a cooling re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com