Uniform particle airflow generation device and method for flow field tracing

A technology for generating devices and particles, applied in the field of aerodynamic research, can solve problems such as particle deposition and agglomeration, and achieve the effects of avoiding deposition and agglomeration, improving production efficiency, and improving mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

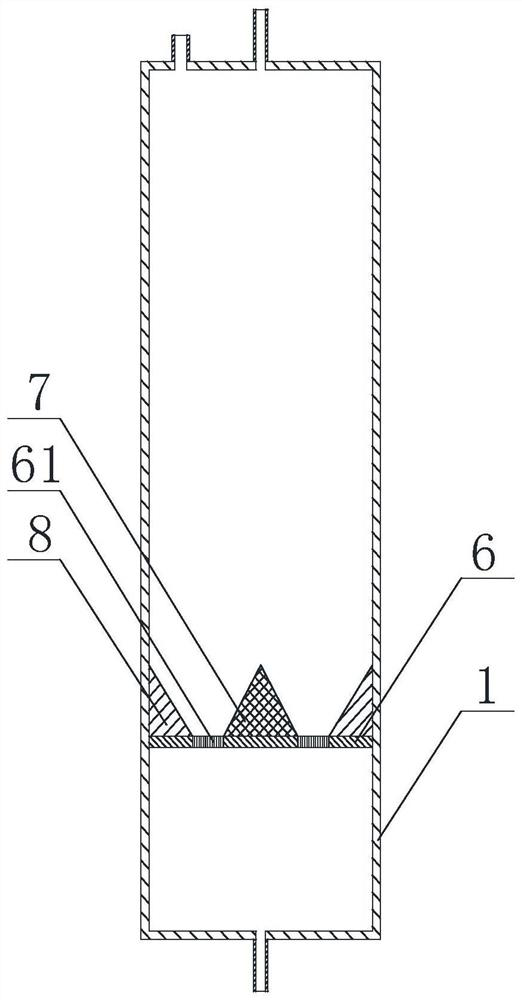

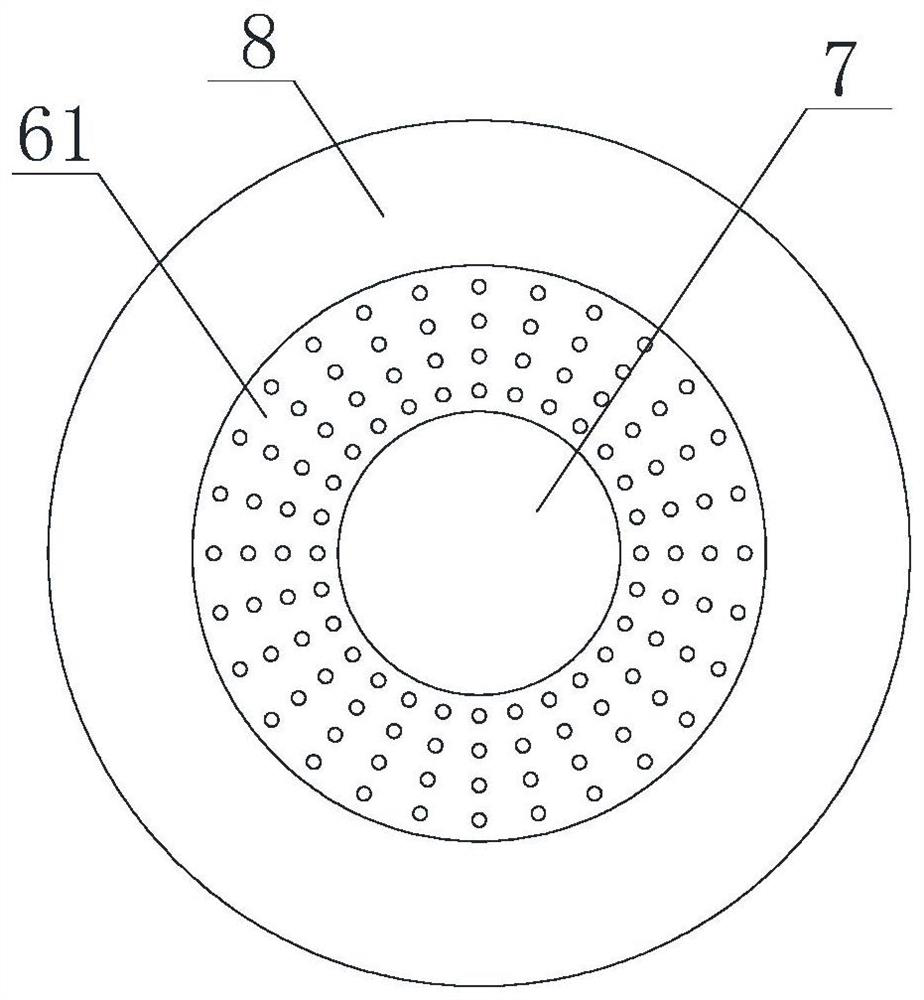

[0054] like Figure 1 to Figure 4 A uniform particle flow generation device for flow field tracing is shown, including a container 1, the top of which is provided with a particle feed port 9 and a gas outlet 2, and the gas outlet 2 passes through a first valve 3 A gas flow guide tube 10 is connected, the bottom of the container 1 is provided with a gas inlet 4, and the gas inlet 4 is connected to a gas source guide tube 11 through a second valve 5, and a first partition is arranged inside the container 1 6. The upper surface of the first partition 6 is provided with an annular body 8 extending along the circumferential direction of the first partition 6, and a cone 7 located inside the annular body 8, the cone 7 and the ring A stacking area for accumulating particles is formed between the shape bodies 8, the width of the stacking area gradually decreases from top to bottom, and an air hole area 61 is also provided on the first partition 6, and an air hole area 61 is arranged o...

Embodiment 2

[0061] On the basis of Example 1, such as Figure 5 , Image 6 and Figure 9 As shown, the bottom of the cone 7 is provided with a driving rod 71, and the lower end of the driving rod 71 moves through the first partition 6, and the driving rod 71 is provided with a lower space located at the first partition 6. The blade 72.

[0062] After the high-pressure gas is filled into the lower space of the first partition through the gas inlet, most of the high-pressure gas hits the tracer particles accumulated in the accumulation area through the first through hole, and a small part of the high-pressure gas hits the blades and drives the drive rod to rotate around its own axis. Drive the cone to rotate. During the rotation of the cone, the tracer particles accumulated on its surface are driven to rotate and move, thereby causing the overall loosening of the accumulated tracer particles, avoiding the deposition and compaction of the tracer particles at the bottom layer, which is not...

Embodiment 3

[0066] On the basis of the above examples, if Figure 5 to Figure 9 As shown, a uniform particle airflow generating device for flow field tracing, the container 1 is provided with a second partition 21 below the first partition 6, and the second partition 21 is provided with several The second through hole 22, the drive rod 71 is provided with a turntable 74 placed on the upper surface of the second partition 21, the turntable 74 is provided with a number of third through holes 76, the turntable 74 can be relatively The second partition 21 rotates, so that the uniform particle flow generating device switches from the pressurized state to the intake state, and switches from the intake state to the pressurized state after the generation of the uniform particle flow is completed;

[0067] In the pressurized state, the second through hole 22 is not aligned with the third through hole 76 , and in the intake state, the second through hole 22 is aligned with the third through hole 76...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com