Novel concrete foundation pouring mold

A concrete foundation and pouring mold technology, applied in the direction of molds, etc., can solve the problems of consuming a lot of time for molds, high cost of molds, waste of materials, etc., and achieve the effect of early production reserve and reusable adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

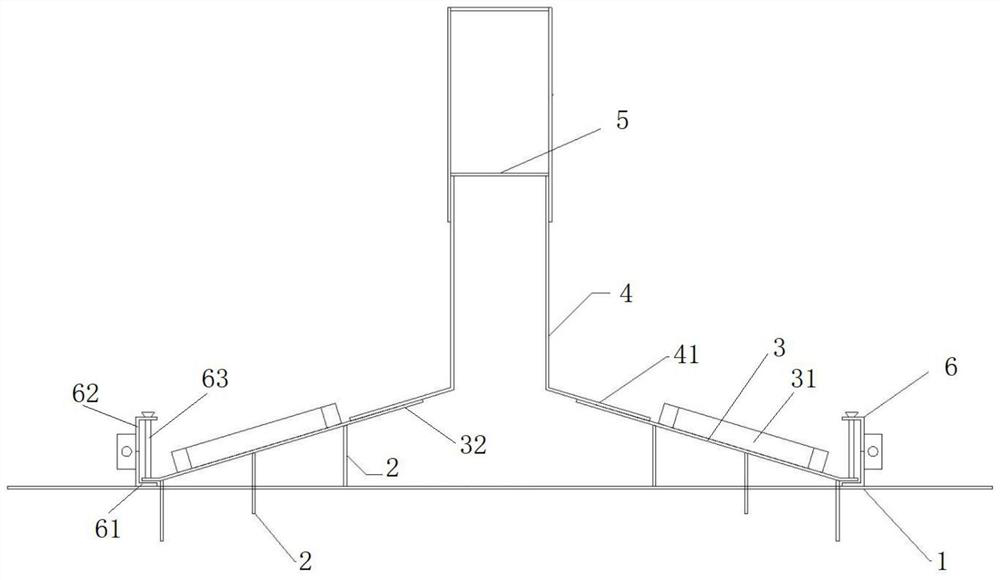

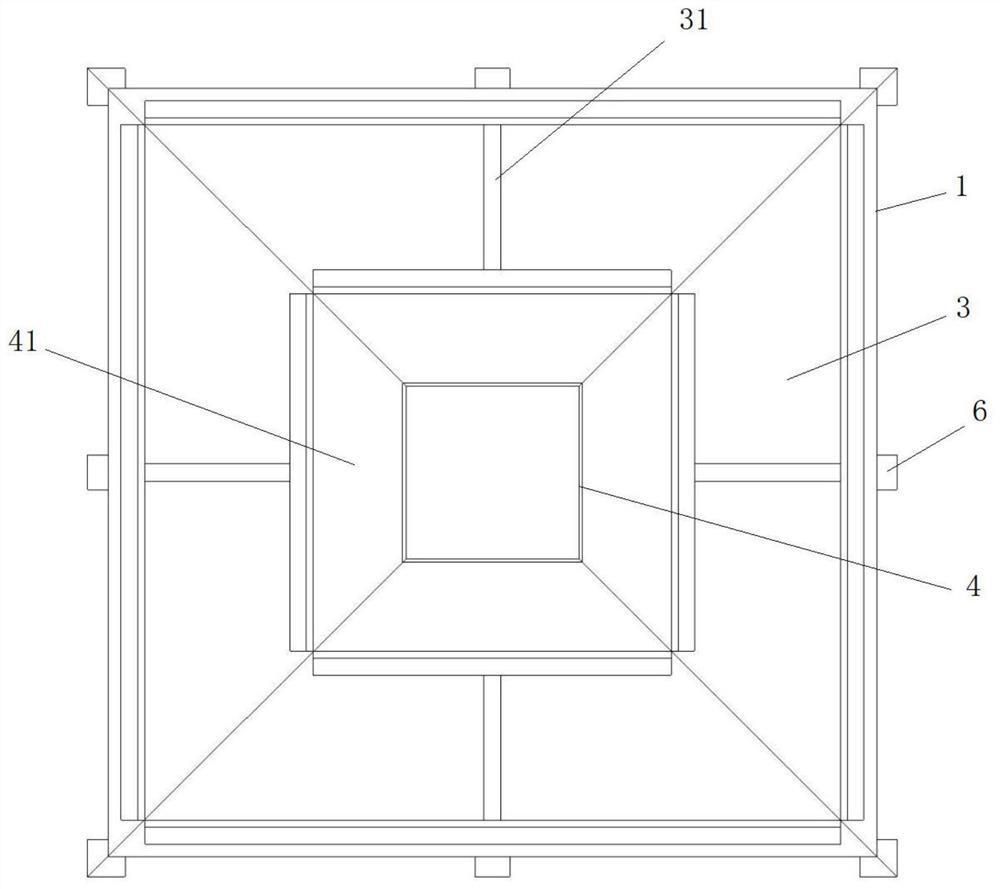

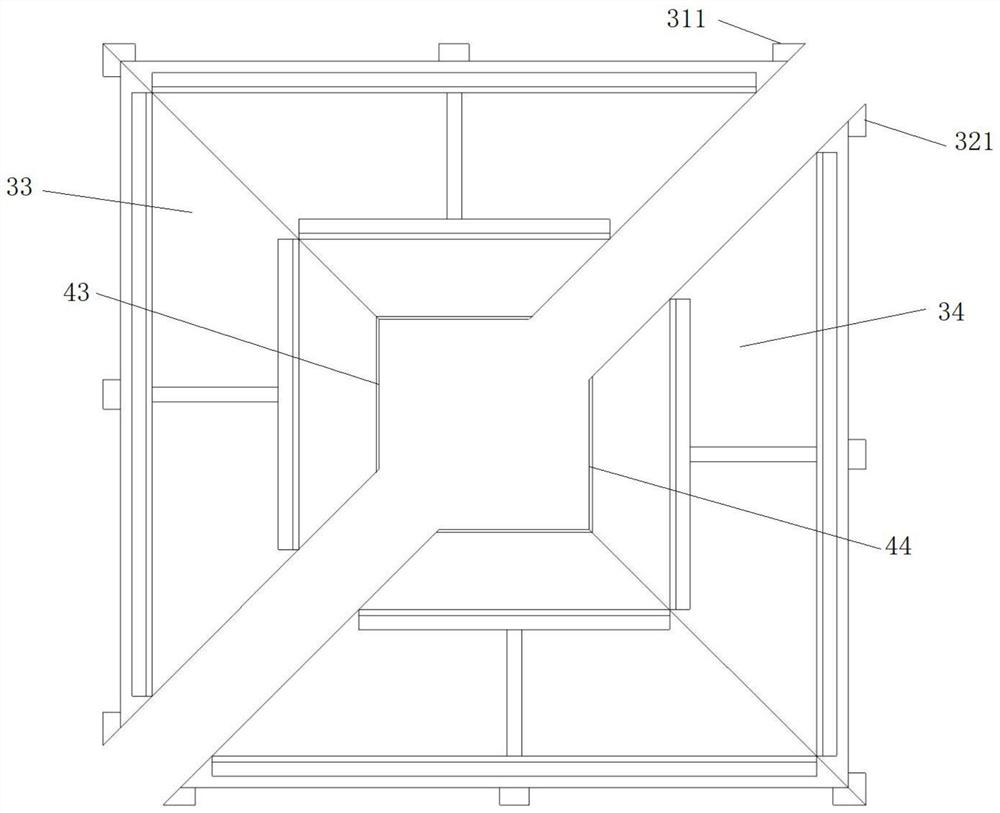

[0028] see figure 1 , figure 2 and image 3 ; The present invention provides a new type of concrete foundation pouring mold in order to pour different specifications of buried prefabricated foundations, including a base formwork platform 1, a bottom edge formwork frame 2, a tapered formwork frame 3 and a column formwork 4; the base formwork platform 1 has a basic mold surface; the bottom mold frame 2 is arranged on the basic mold surface; the tapered mold frame 3 has a bottom opening and a top opening, and the bottom opening of the tapered mold frame 3 covers the The bottom frame 2, the inner cover wall of the tapered frame 3 is closely attached to the top frame of the bottom frame 2, and the top opening of the tapered frame 3 is provided with a first lap connecting slope 32; and the bottom of the column mold 4 communicates with the top opening of the tapered mold frame 3, and is provided with a second overlapping slope 41 overlapping with the first overlapping slope 32, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com