Composite mechanical arm capable of moving in multiple directions

A multi-directional and composite technology, applied in the field of robotic arms, can solve the problems of inconvenient disassembly and assembly, obstacles to maintenance and repair of internal components of the base, and low maintenance convenience of composite robotic arms, and achieves the effect of easy installation and improved maintenance convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

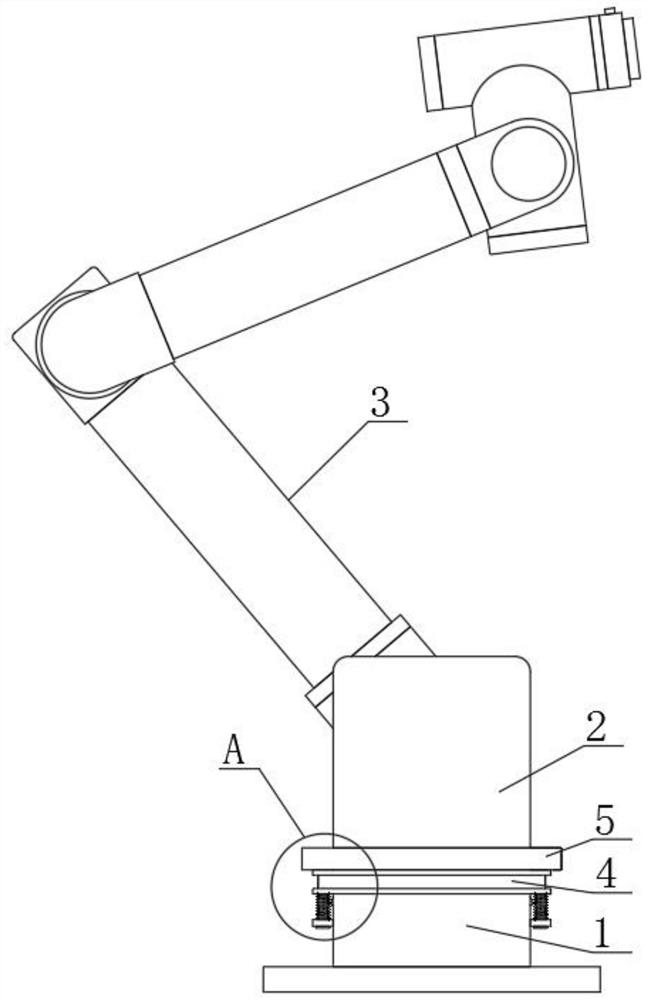

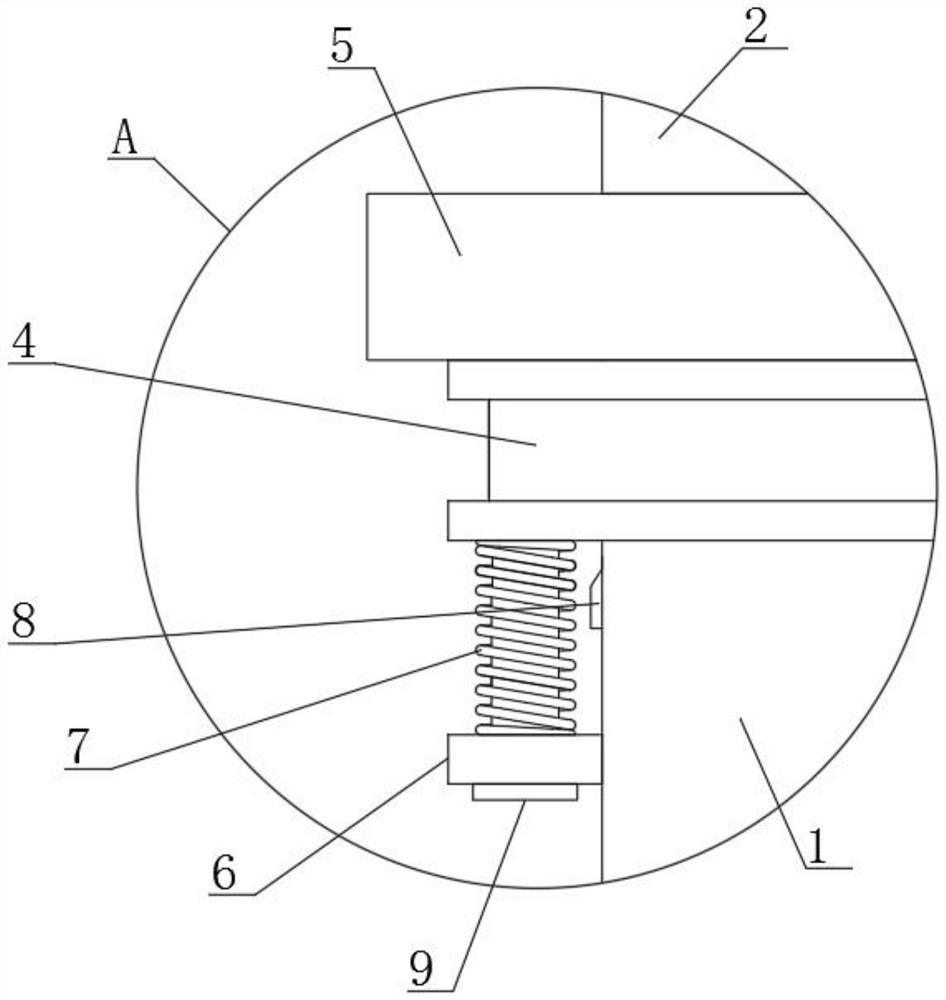

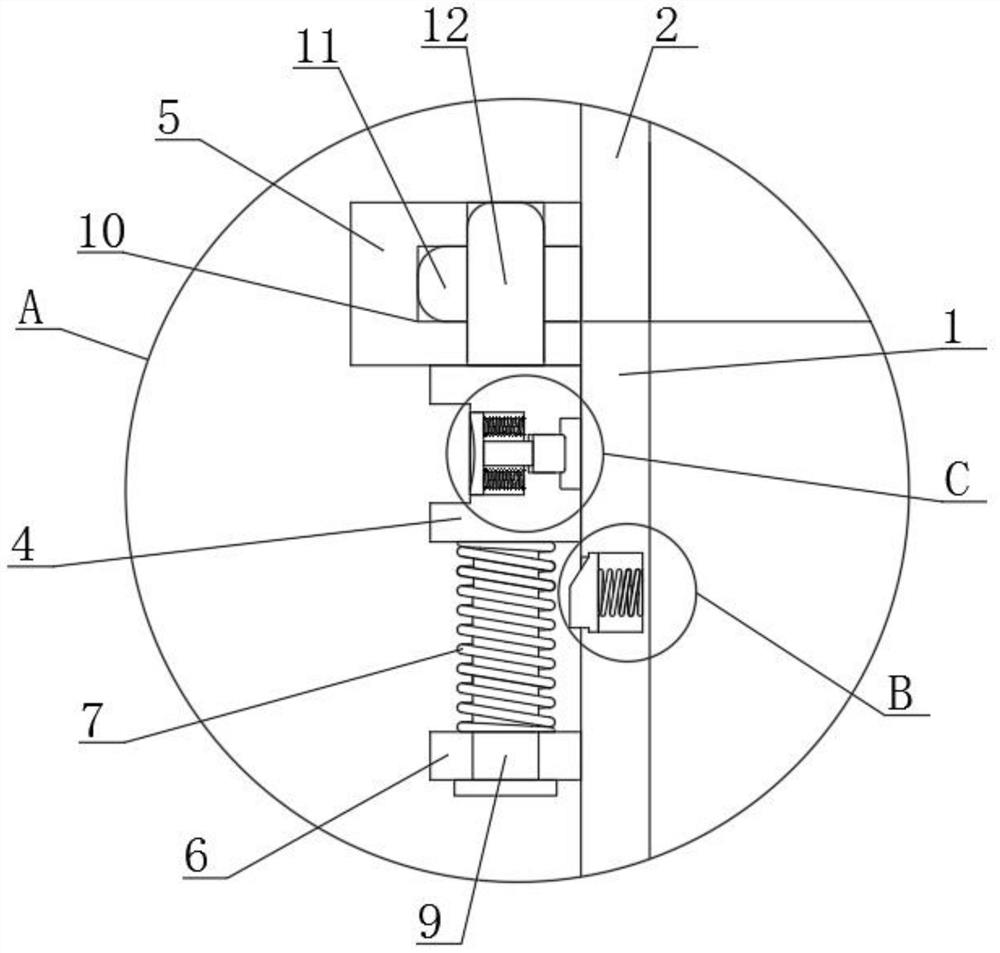

[0026] see Figure 1 to Figure 7 , the present invention provides a technical solution: a compound mechanical arm with multi-directional movement, including a base 1 and a multi-directional rotating arm 3 connected to the base 1 through a rotating shaft. A seat cover 2 is installed on the top of the base 1. The top surface of the seat cover 2 is welded and fixed with an annular base 5, and the bottom surface of the seat cover 2 is symmetrically welded with two end plates 11, and the inner portion of the annular base 5 is symmetrically provided with two arc-shaped slide grooves 10 corresponding to the end plates 11. , the top surface of the annular base 5 is also provided with two disassembly openings 13 corresponding to the end plate 11, and the disassembly opening 13 communicates with the arc chute 10, so that the end plate 11 can enter the arc through the disassembly opening 13. In the shaped chute 10, the surface of the base 1 is slidably connected with the snap ring 4 rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com