Splash protection assembly for blade electron beam welding and blade welding method

A technology of electron beam welding and welding joints, which is applied in the field of aero-engine blade welding, can solve problems affecting the surface quality of blades, reduce the impact of spatter, improve quality, and be easy to install and disassemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

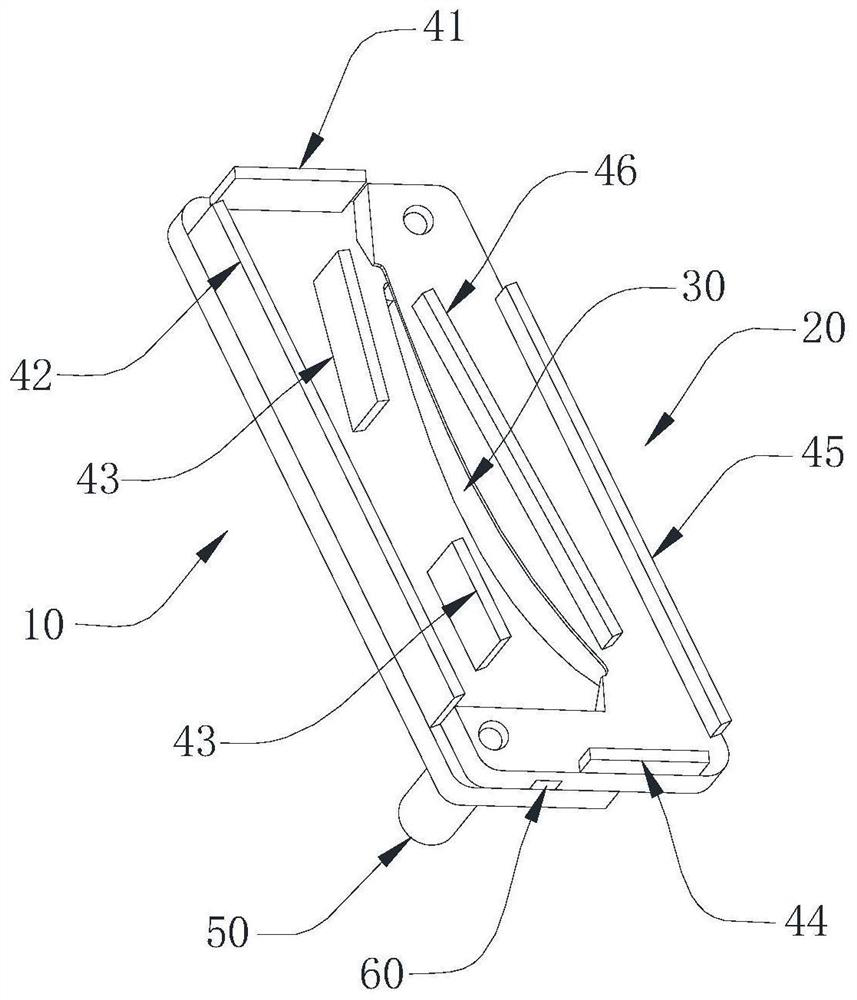

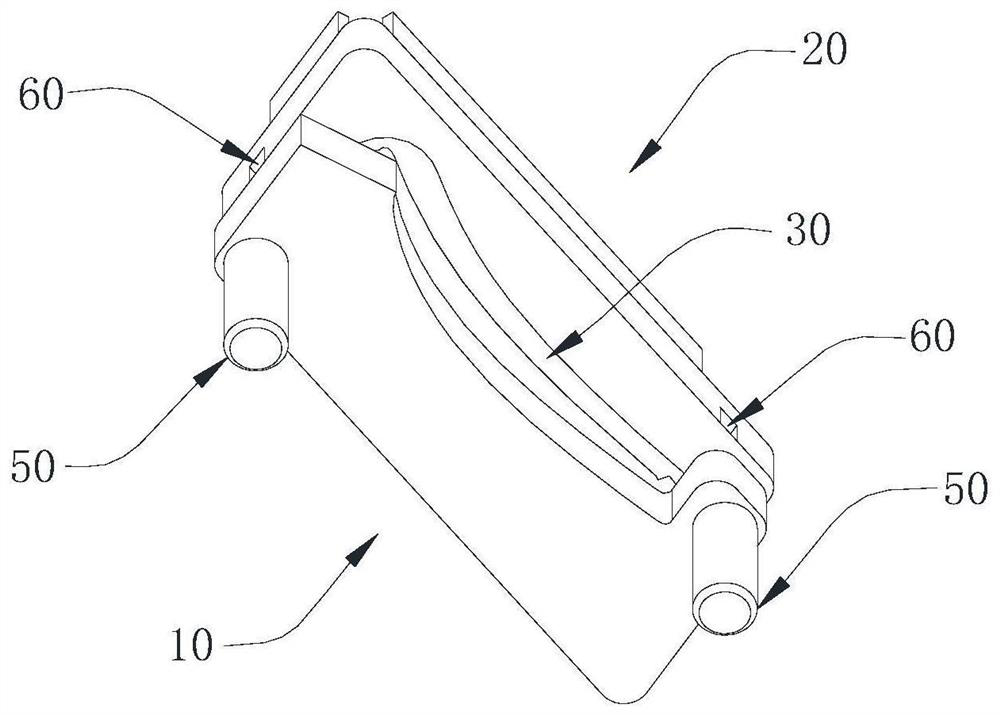

[0043] Please refer to figure 1 with figure 2 A splash protection assembly for blade electron beam welding, including: the first stopper 10 and the second stop 20. After the first stopper 10 and the second stopper 20 are connected to each other, the clamping space 30 is formed to hold the front side of the air engine blade 70, the first stop 10 and the second stop 20 are disposed. There are multiple baffles for protection for blade 70 and splash protection.

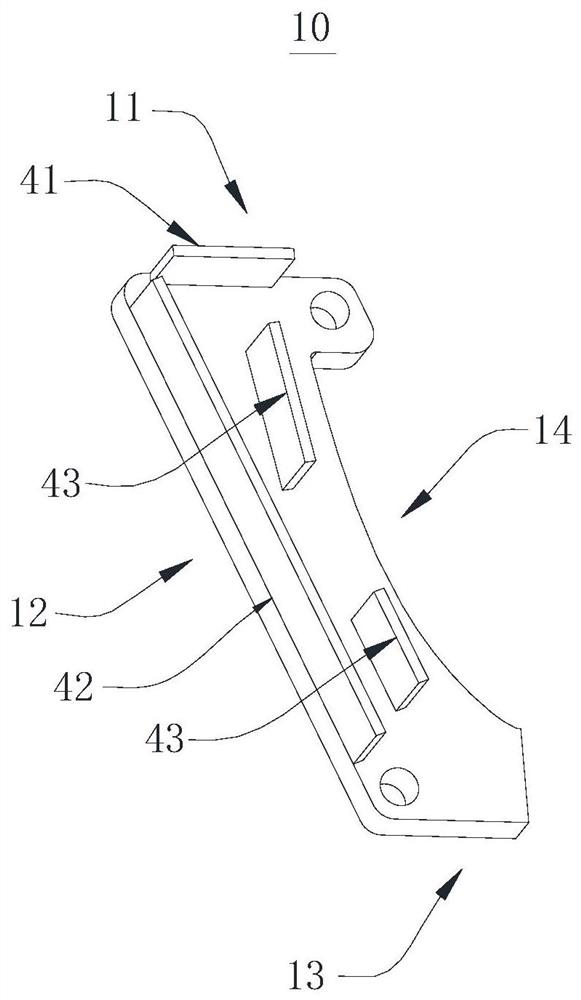

[0044] Please refer to Figure 1 to 3 The first stopper 10 includes a first side 11, a second side 12, a third side surface 13, and a concave side 14 in sequentially disposed. The first baffle 41 and the second baffle 42 are respectively provided at the top of the first side surface 11 and the second side surface 12. The concave surface 14 is the side surface of the depression, is provided with the leaf back of the blade 70, and a third baffle 43 is provided at a position close to the concave surface side 14, in the present em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com