Instrument for bi-directionally and uniformly adding graphite powder before crack detection of stainless steel watch case

A technology of graphite powder and stainless steel, applied in the field of watches, can solve problems such as failure to meet standards, scattered graphite powder, and increased cost, and achieve the effect of facilitating later detection, preventing scattering and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

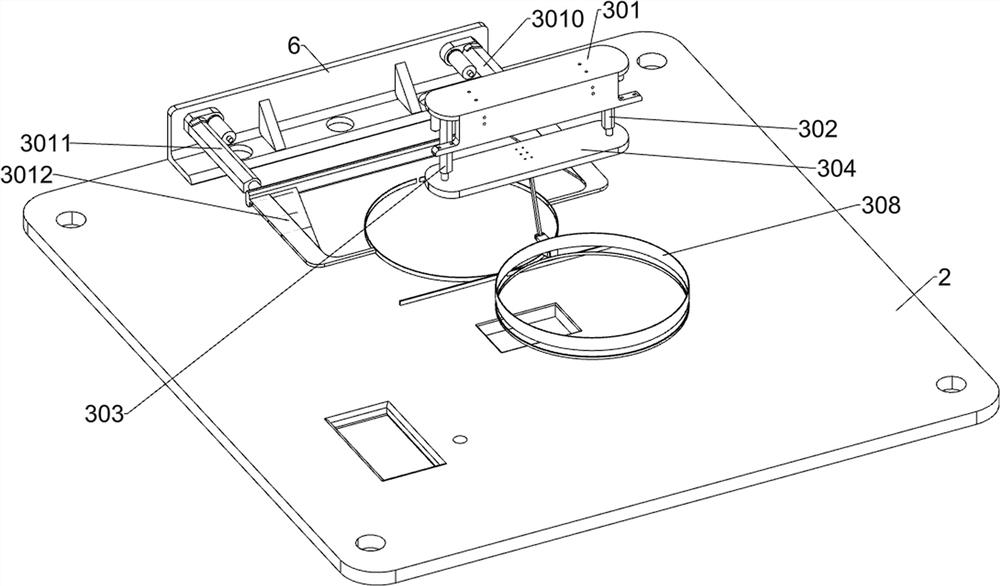

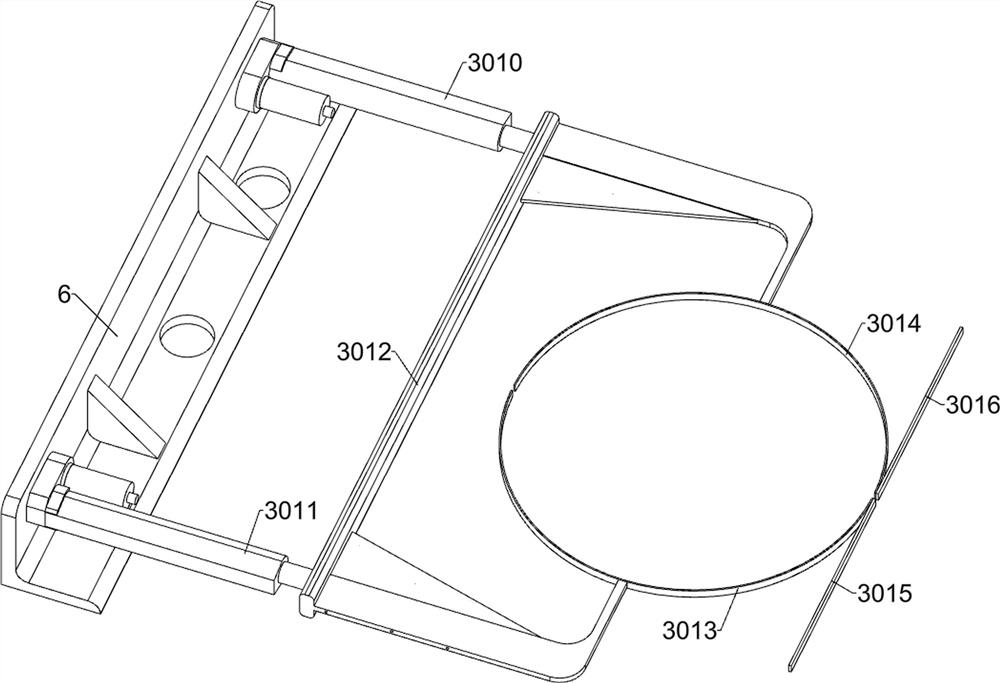

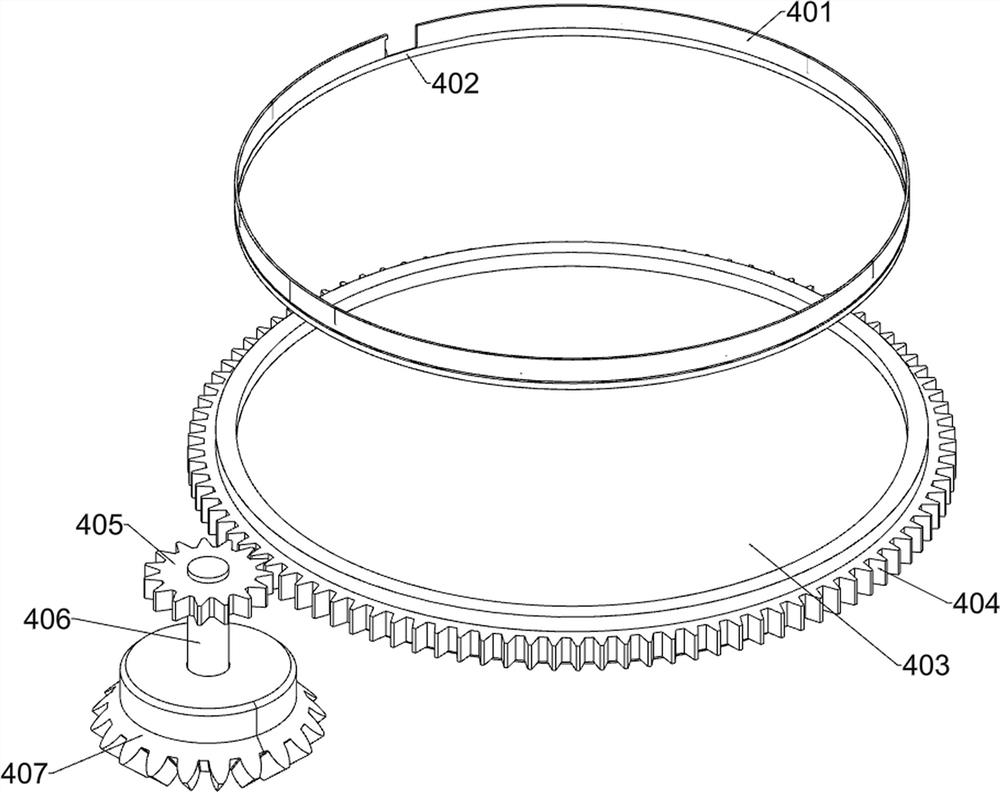

[0035] A two-way uniform graphite powder adding instrument before crack detection of stainless steel watch case, such as Figure 1-3 As shown, it includes a foot 1, a bottom plate 2, a first fixing frame 3, an analog watch case 4, a graphite powder storage bucket 5, a second fixing frame 6, a blanking assembly, an inner ring processing assembly and an outer ring processing assembly; the bottom plate 2. The four corners below are fixed with a set of feet 1; the bottom plate 2 is fixed with the first fixed frame 3; the bottom plate 2 is connected with the second fixed frame 6 by bolts; powder coated on the surface of the analog watch case 4; an inner ring processing assembly for processing graphite powder on the inner ring of the surface of the analog watch case 4 is installed on the blanking assembly; The outer ring processing component of the graphite powder on the outer ring of the simulated watch case 4 surface; the blanking component is fixedly connected to the graphite pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com