Heating smoking set calibration method and system

A calibration method and technology for smoking utensils, applied in tobacco and other directions, can solve the problems of difficulty in real-time detection of temperature values, detection accuracy can only reach ±2.5°C, delay in calculation process, etc., so as to reduce calculation delay, improve accuracy and reliability, and improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

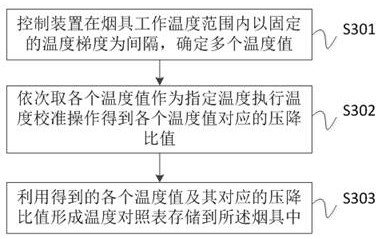

[0067] refer to image 3 , the method of the present embodiment includes a temperature measurement calibration step, and the temperature measurement calibration step includes:

[0068] S301: The control device determines multiple temperature values at intervals of a fixed temperature gradient within the working temperature range of the smoking appliance. Specifically, the temperature value is an integer, and the fixed temperature gradient is 1°C. For example, the working temperature range of the smoking appliance is 200-400 °C, the multiple temperature values are: 200, 201, 202, ..., 398, 399, 400 °C.

[0069] S302: Taking each temperature value as the specified temperature in turn to perform a temperature calibration operation to obtain a pressure drop ratio corresponding to each temperature value;

[0070] S303: Use the obtained temperature values and their corresponding pressure drop ratios to form a temperature comparison table and store them in the smoking applianc...

Embodiment 2

[0077] refer to Figure 4 , the method of the present embodiment also includes a temperature measurement and calibration step, and the temperature measurement and calibration step includes:

[0078] S401: The control device selects several temperature values within the working temperature range of the smoking appliance, and sequentially takes each temperature value as a specified temperature to perform a temperature calibration operation to obtain a pressure drop ratio corresponding to each temperature value. Specifically, the several temperature values are integers.

[0079] Wherein, the temperature calibration operation described in S401 includes:

[0080] 1) Start the infrared thermal imaging thermometer to collect the thermal image data of the smoking set in real time;

[0081] 2) After performing image processing on the thermal image data collected in real time, the temperature value of the smoking set is determined. Specifically, after image processing on the therm...

Embodiment 3

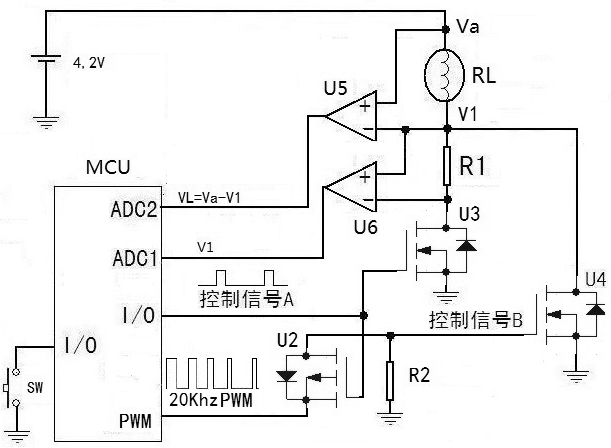

[0100] When the smoking appliance is started and heated to the preset working temperature, the user can suck the cigarette. When the suction action occurs, the external air flows through the cigarette and the heating device through the air passage of the smoking appliance. Due to the cooling effect of the airflow, the cigarette The heat of the branch and the heating device is taken away by the gas flowing through it, causing the temperature of the heating device to drop, and the TCR value corresponding to the temperature drop of the heating device changes, which is finally reflected in the change of the V1 / VL value detected by the smoking appliance. As mentioned above, the present invention can accurately measure the temperature, and the MCU detects that the temperature drop of the smoking appliance exceeds the preset temperature difference (2°C) and the duration exceeds a certain preset value in the preset time length range (300-800ms) , it is determined that a puff has occurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com