Efficient battery production process capable of avoiding wiping of liquid injection opening and realizing direct welding of sealing piece

A welding sealing and production process technology, applied in battery pack parts, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of easy generation of dust, need labor, low production efficiency, etc., to improve work efficiency and reduce wiping process, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

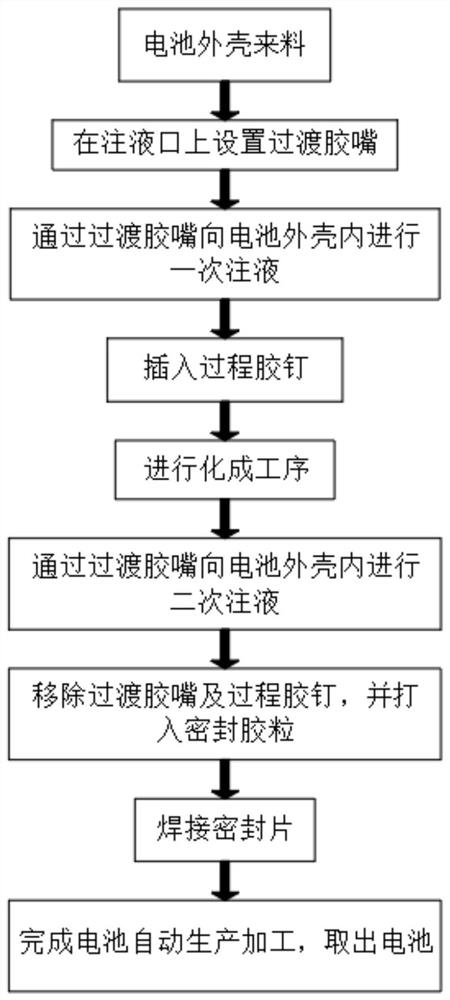

[0024] see figure 1 , the present invention provides a highly efficient battery production process in which a wipe-free liquid injection port can be directly welded to a sealing sheet, comprising the following steps:

[0025] Step 1: The battery casing is supplied, and the battery casing is placed under the liquid injection mechanism.

[0026] Step 2: The material transfer mechanism picks up a transition rubber nozzle, and inserts the transition rubber nozzle into the liquid injection port of the battery case.

[0027] Step 3: The liquid injection mechanism moves to the top of the transition nozzle, and injects the electrolyte into the battery case. After the liquid injection mechanism injects the electrolyte into the battery case, when the electrolyte overflows, etc., the overflowed electrolyte will remain on the transition nozzle to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com