Modeling simulation method for ablation behavior of C/C composite material nozzle of solid rocket engine

A composite material, solid rocket technology, used in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as multiphase flow, ablation effects, and can not represent the actual situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

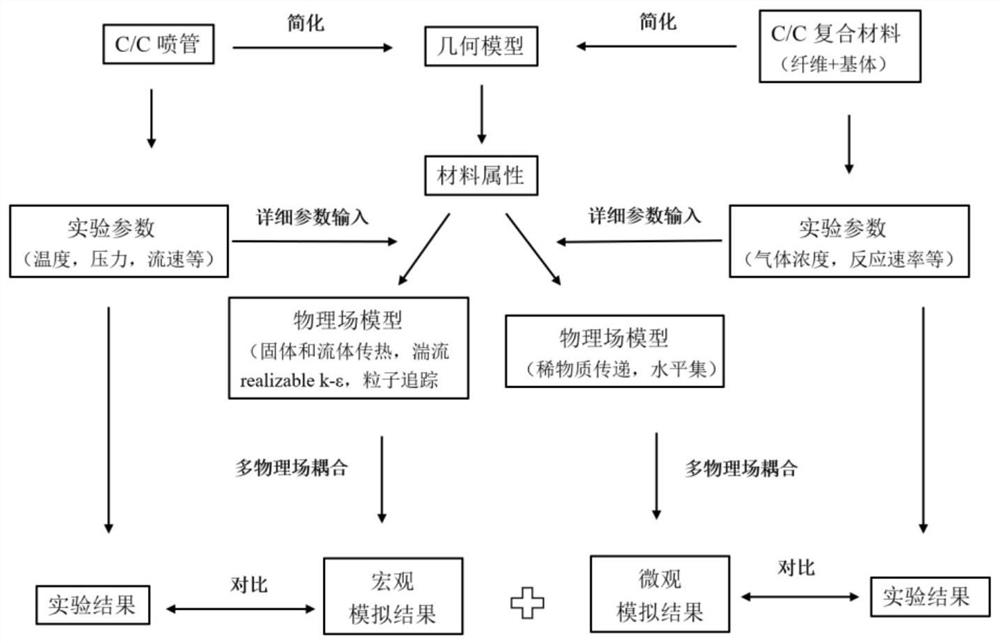

[0097] Such as figure 1 As shown, a solid rocket motor C / C composite material nozzle ablation behavior modeling and simulation method includes the following steps:

[0098] Step 1: Establish the geometric model of the nozzle of the C / C composite material;

[0099] The nozzle is an important energy conversion component of the rocket engine, and it has an important influence on the performance of the engine. In order to accelerate the gas flow velocity from subsonic velocity to supersonic velocity, a Laval nozzle whose cross-sectional shape first converges and then expands is used. In order to reduce calculation time and calculation memory, based on the symmetry of the nozzle and composite material structure, a two-dimensional axisymmetric geometric mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com