Tool clamp for manufacturing elevator mirror surface decoration wallboard

A tooling fixture and wall panel technology, which is applied to manufacturing tools, workpiece clamping devices, connecting components, etc., can solve problems such as wall panel deformation and image distortion, and achieve the purpose of preventing glue shrinkage and deformation, consistent glue thickness, and simple and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

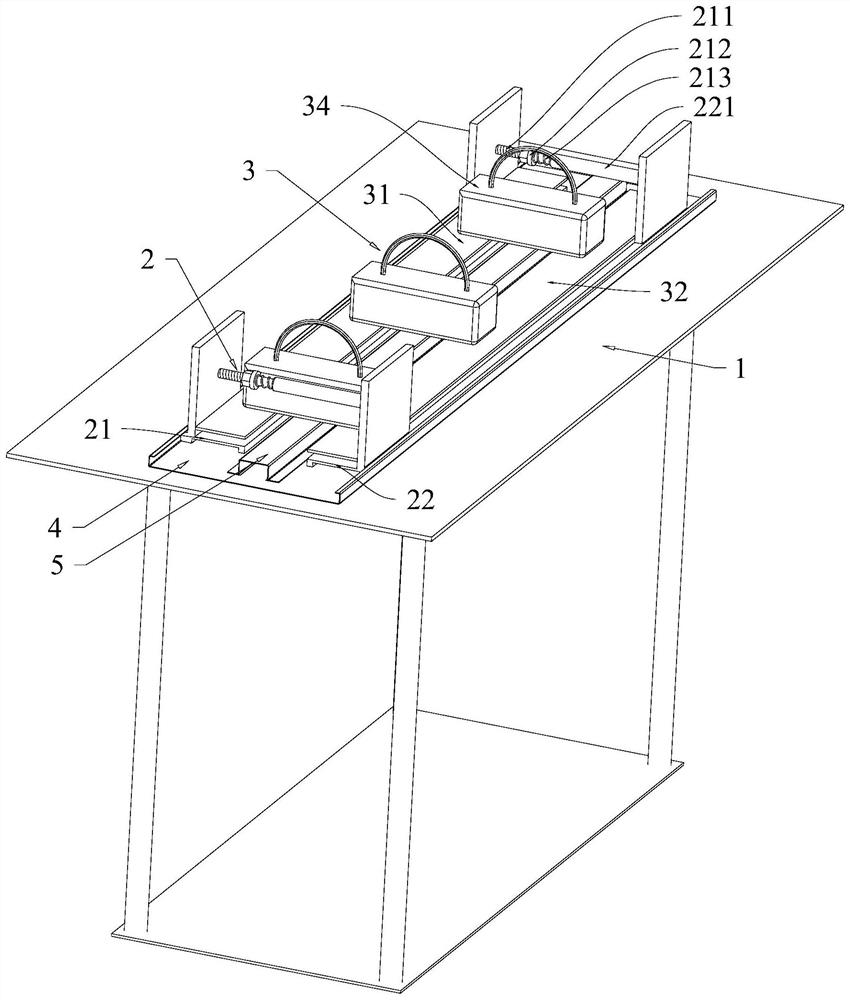

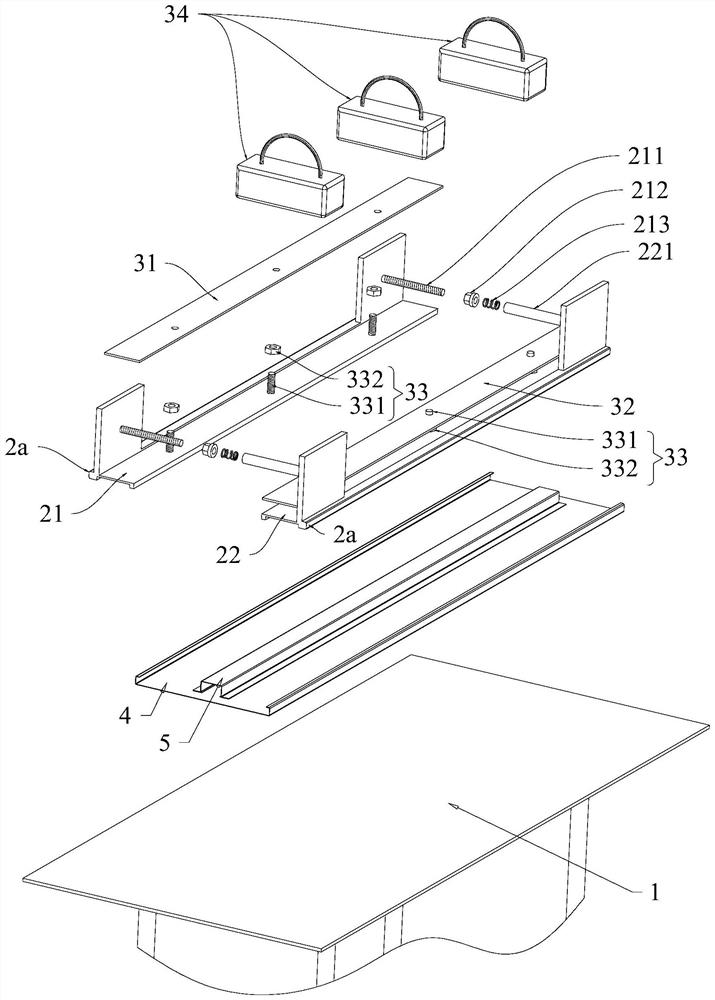

[0026] Such as Figure 1 to Figure 2 A tooling fixture for making elevator mirror decorative wallboards as shown, includes a tooling platform 1 for placing the wallboard 4, and above the tooling platform 1, there is a device for tightening the wallboard 4 from the inside and flattening it. The tensioning component 2 on the tooling platform 1, the pressurizing component 3 for pressing on the reinforcement rib 5 to limit its deformation.

[0027] In the present invention, the reinforcing rib 5 is glued to the middle part of the wallboard 4 by glue. After the reinforcing rib 5 is pasted, the glue will dry and shrink, and the thickness of the glue may also be inconsistent. In order to prevent the deformation of the wallboard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com