Environment-friendly auxiliary device with function of preventing size leakage of size tank and used for sizing machine

An auxiliary device and technology of sizing machine, applied in the field of textile machinery, can solve the problems of sizing tank leakage, waste of resources, etc., and achieve the effects of saving resources, reducing production costs, and improving equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

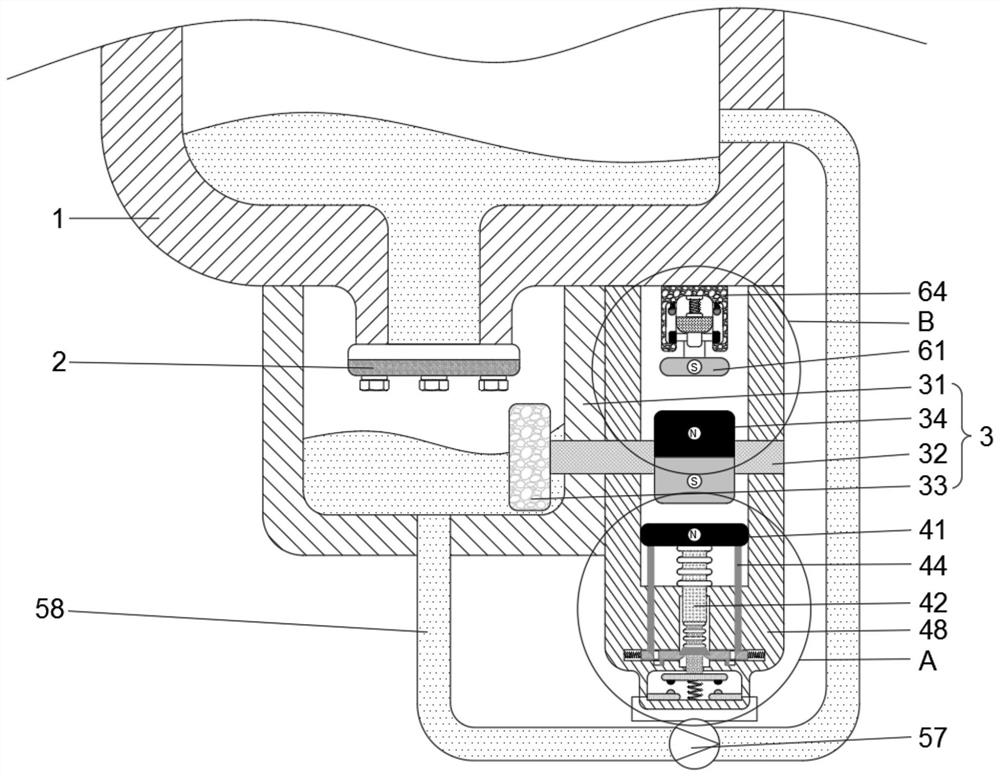

[0023] see figure 1 , an environmental protection auxiliary device for a sizing machine with the function of preventing pulp leakage from a size tank, comprising a size tank 1, a flange 2 fixedly connected to the bottom of the size tank 1, a detection mechanism 3 fixedly connected to the bottom of the size tank 1, and a detection mechanism 3 The bottom is movably connected with a switching mechanism 4, the bottom of the switching mechanism 4 is fixedly connected with a circulation mechanism 5, and the top of the detection mechanism 3 is fixedly connected with an alarm mechanism 6.

[0024] The detection mechanism 3 is triggered after the slurry tank 1 leaks, and the detection mechanism 3 rotates to realize the function of automatic detection of slurry leakage and improve the safety of the equipment; the rotation of the detection mechanism 3 triggers the switching mechanism 4, and the movement of the switching mechanism 4 triggers the circulation mechanism 5, and the circulation...

Embodiment 2

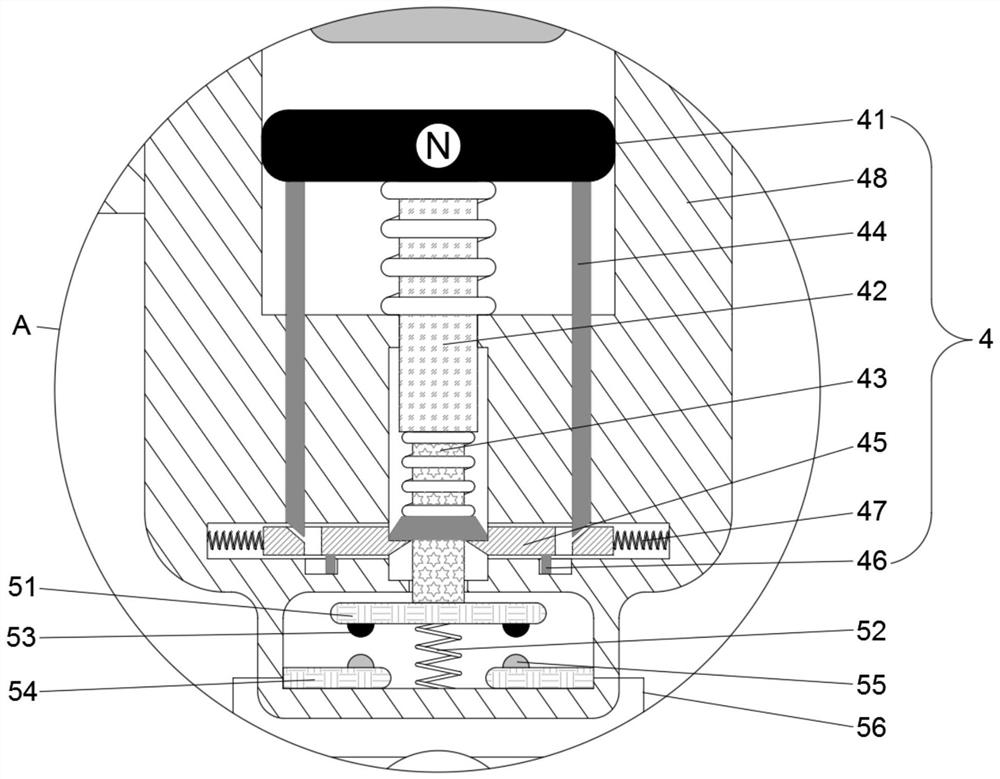

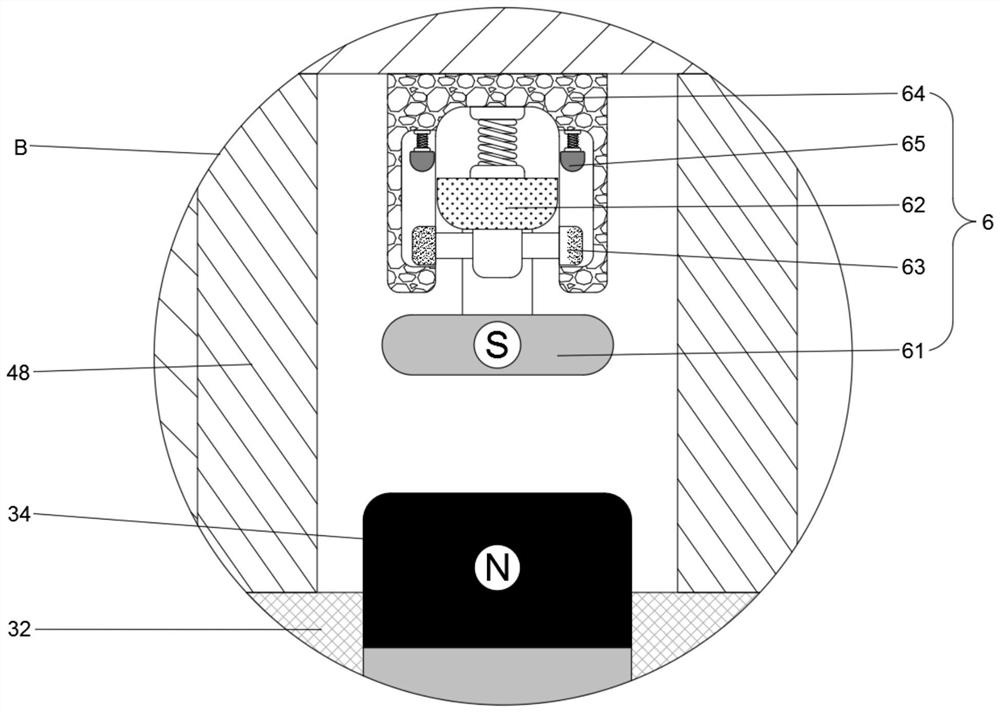

[0029] see Figure 1-3 , an environmental protection auxiliary device for a sizing machine with the function of preventing pulp leakage from a size tank, comprising a size tank 1, a flange 2 fixedly connected to the bottom of the size tank 1, a detection mechanism 3 fixedly connected to the bottom of the size tank 1, and a detection mechanism 3 Including a detection pool 31, the right side of the detection pool 31 is movably connected with a rotating shaft 32, the left end of the rotating shaft 32 is fixedly connected with a coil spring 33, the coil spring 33 is made of a bimetal sheet, and is used for temperature sensing to drive the rotating shaft 32 to rotate, and the right end of the rotating shaft 32 is fixedly connected with a The detection magnet 34 is used to trigger the alarm mechanism 6 and the switching mechanism 4. The bottom of the detection mechanism 3 is movably connected to the switching mechanism 4. The switching mechanism 4 includes a switching magnet 41. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com