Sun-resistant fabric with honeycomb structure and weaving method thereof

A honeycomb structure and fabric technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve problems such as high pilling and snagging risk, sunscreen effect is not washable, and sunscreen is unfavorable, so as to improve wearing experience and appearance structure Novelty, the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

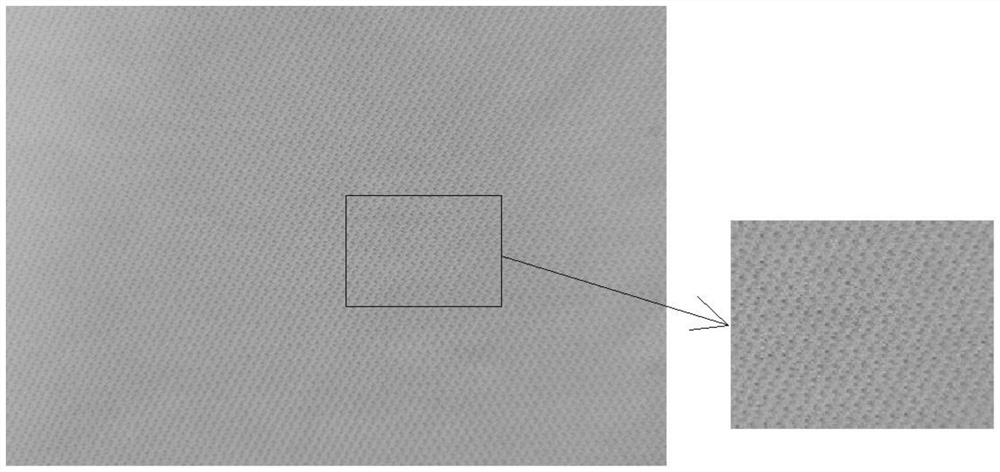

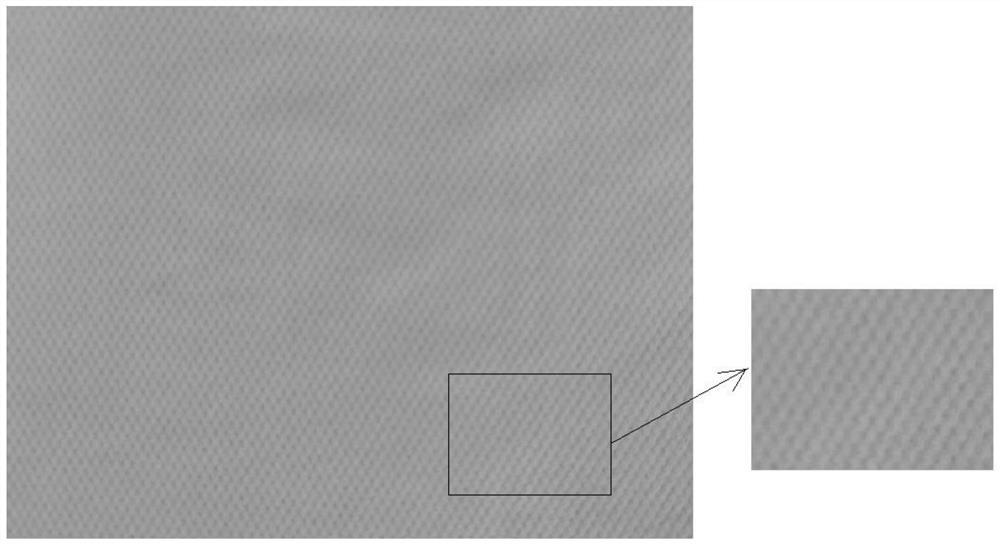

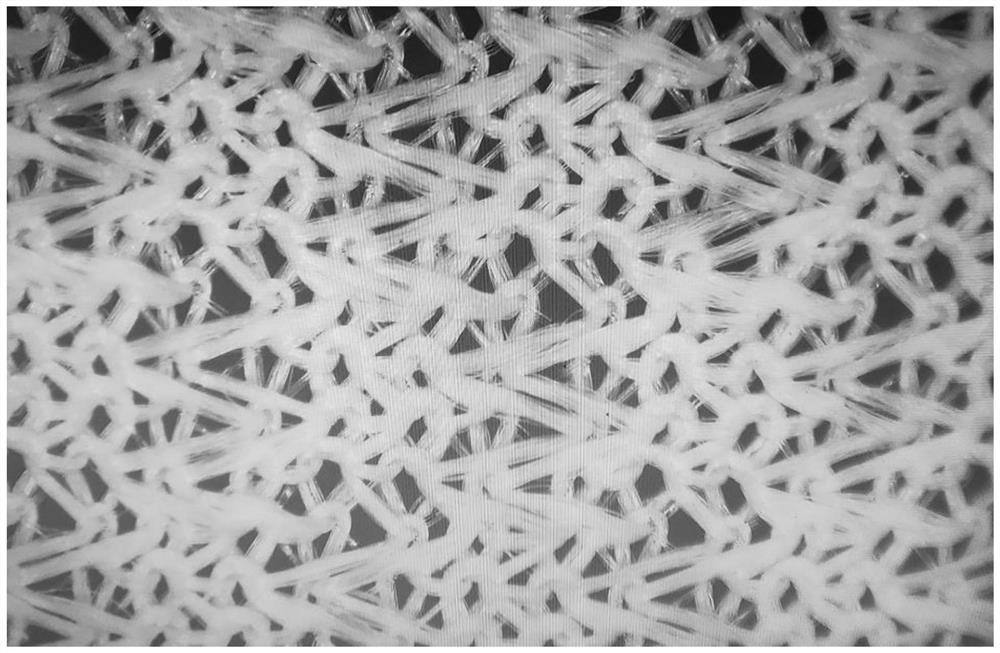

[0077] Example: Reference Figure 1-7 , the present invention mainly solves the problems of existing sunscreen fabrics such as poor sun protection, poor air permeability, poor skin-friendliness, poor extension, monotonous appearance and not dry enough, etc., and provides a sunscreen fabric with a honeycomb structure. The appearance structure diagram of the sunscreen fabric can be referred to figure 1 , figure 2 Shown, enlarged structure diagram reference image 3 As shown, it can be used to weave sun protection clothing. The sun protection fabric includes several cyclically repeated knitting units, and the knitting units include the first yarn, the second yarn, and the third yarn that are knit with floating threads in the knitting needle area of the needle bed. , the knitting needle area is provided with a number of needle positions distributed in a two-dimensional coordinate system array; the first yarn includes the first yarn a100, the first yarn b101; the second yarn in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com