2-acetylpyrazine continuous recrystallization device and method and application thereof

A technology of acetylpyrazine and crystallization device, applied in the field of 2-acetylpyrazine continuous recrystallization device, can solve problems such as low production efficiency, low yield, safety and environmental protection risks and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

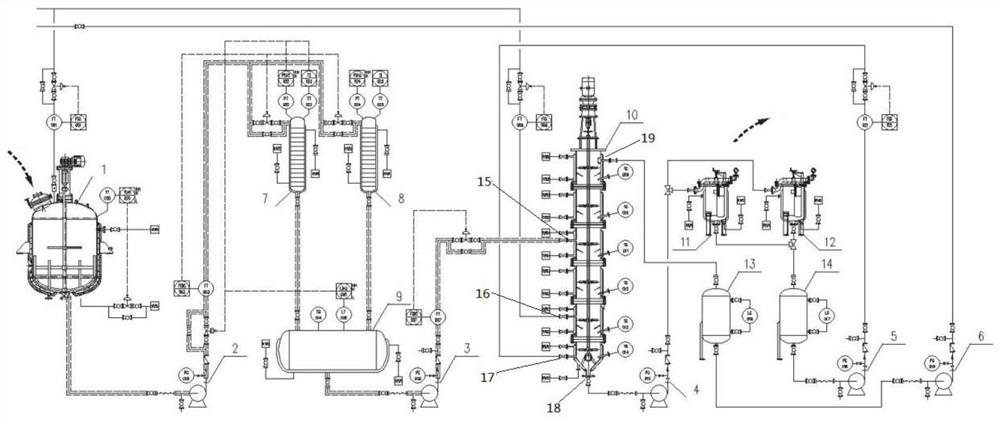

[0080] Such as figure 1 As shown, it is a 2-acetylpyrazine continuous recrystallization device disclosed in this embodiment:

[0081] The dissolution device 1, crude product transfer pump 2, decolorization device a7 or decolorization device b8, turnover tank 9, feed pump 3, crystallizer 10, slurry pump 4, filter a11 or filter b12, reuse mother liquor tank 14 , Recycling mother liquor pump 5 is sequentially connected through pipelines, and crystallizer 10 is sequentially connected with mother liquor tank 13 and mother liquor pump 6 through second discharge port 19 through pipelines to form a continuous recrystallization production line.

[0082] The crystallizer 10 is provided with six sections from bottom to top, the lower temperature is higher than the upper temperature, the first feed port 15 is located in the fourth section, the second feed port 16 is located in the second section, and the third feed port 17 is located in the second section. In the first section, the first...

Embodiment 2

[0093] The specific steps for the continuous recrystallization of 2-acetylpyrazine using the device described in Example 1 are as follows:

[0094] Step ①: Put 1056kg of crude 2-acetylpyrazine into the dissolving device 1, and set the cumulative feed amount of the solvent to 8m 3 , the solvent is automatically metered by the flowmeter and added to the dissolving device; set the temperature of the kettle to 47°C, then open the jacketed hot water inlet regulating valve of the dissolving device 1, and start heating until the crude 2-acetylpyrazine is completely dissolved to solvent, and stabilized at around 47°C.

[0095] Step ②: Open the hot water inlet and outlet valves of the jacket of decolorizing device a7 or decolorizing device b8 and turnover tank 9, and feed hot water at 50°C to maintain the internal temperature of decolorizing device a7 or decolorizing device b8 and turnover tank 9 at 45 ~50°C; set the feed flow rate of the crude product solution to 500L / h, the dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com