Food packaging equipment for food processing

A packaging equipment, food processing technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to measure food quality, debris is not easy to clean, food packaging damage, etc., to improve cleaning convenience, reduce equipment The effect of sealing and improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

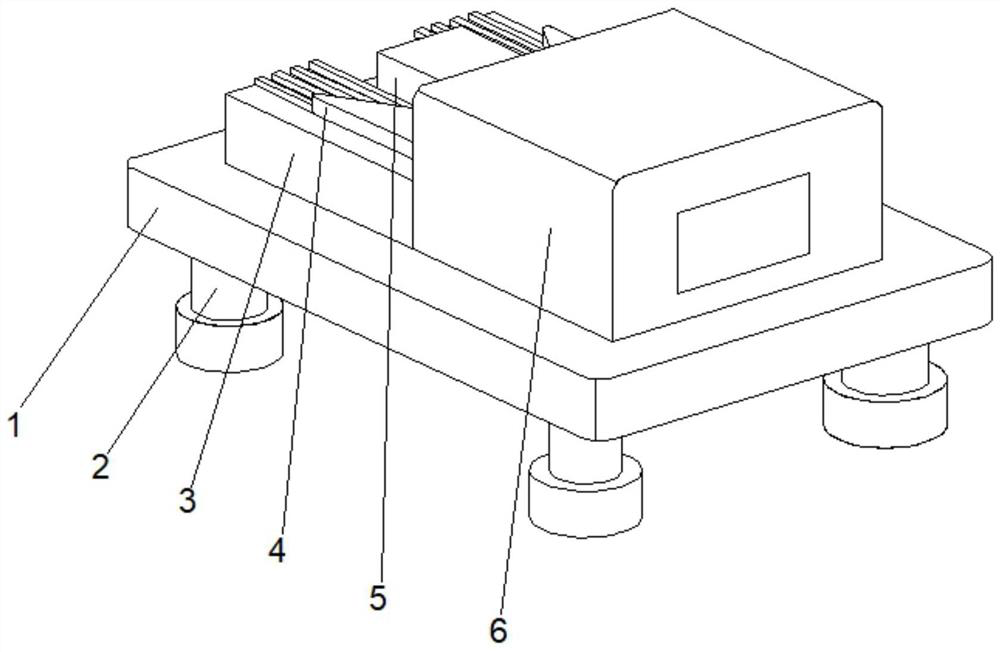

[0035] see Figure 1-2, the present invention provides a technical solution: a food packaging equipment for food processing, including a bottom plate 1, support columns 2 are fixedly connected to both sides of the bottom of the bottom 1, and a sealing device 6 is fixedly connected to the top right side of the bottom plate 1, The left side of the top of the bottom plate 1 is fixedly connected with a support 3 , and the middle position of the top of the support 3 is fixedly connected with a collection box 5 , and the top of the support 3 is positioned at both sides of the collection box 5 and is provided with a moving plate 4 .

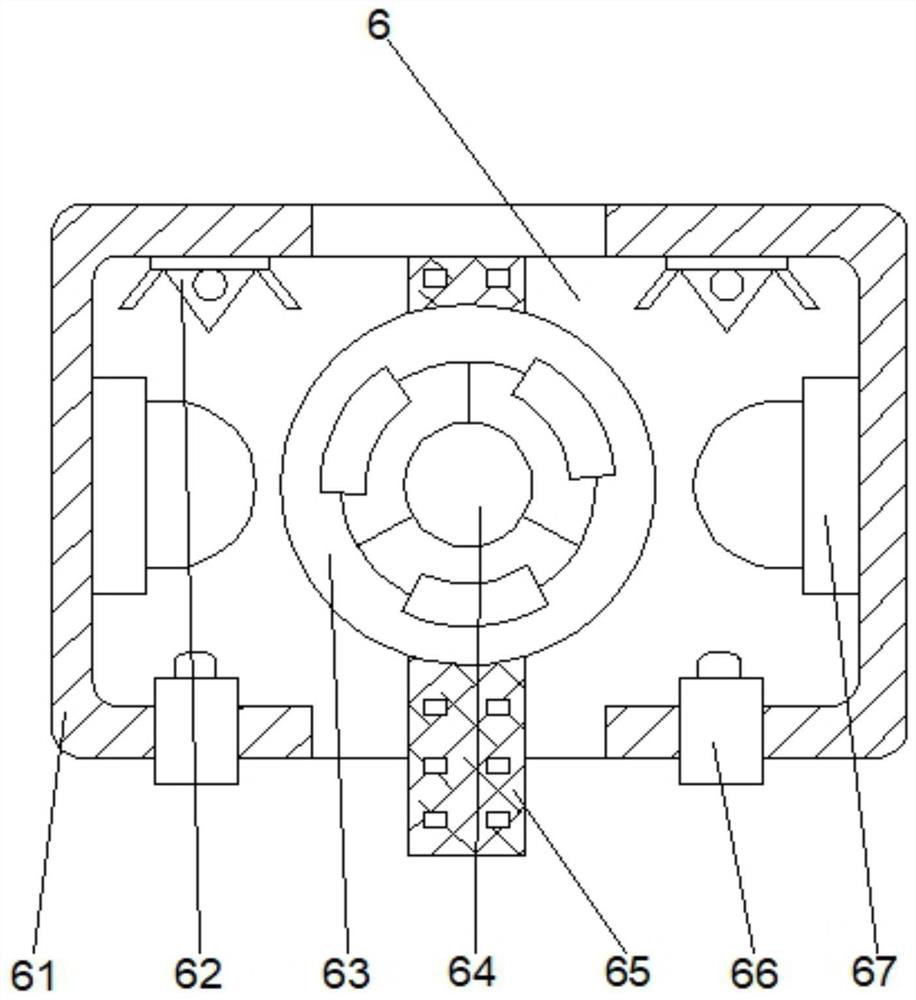

[0036] Wherein, the sealing device 6 comprises an outer frame 61, a transmission belt 65 is arranged in the middle of the top of the inner cavity of the outer frame 61, and the inner cavity top of the outer frame 61 is located at both sides of the transmission belt 65 and is fixedly connected with a display lamp 62. The outer walls on both sides of the ...

Embodiment 2

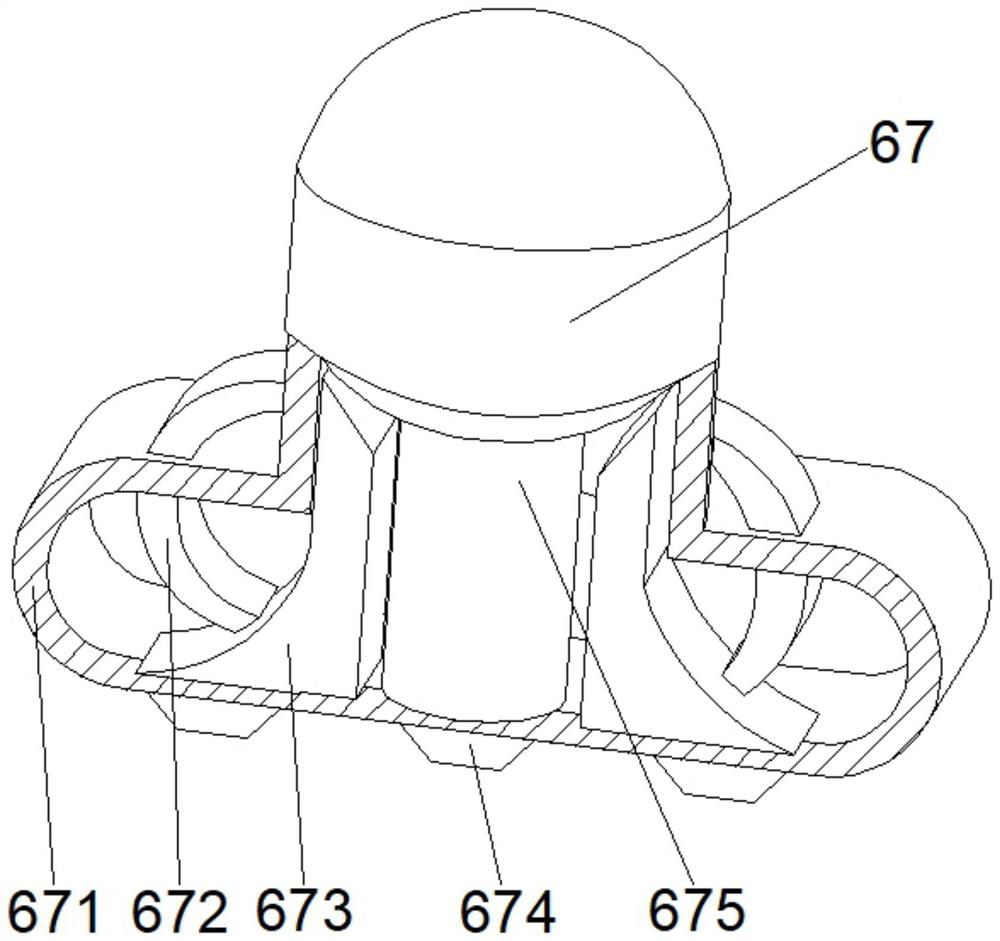

[0039] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the linkage mechanism 67 includes a linkage frame 671, and the middle position of the bottom of the inner cavity of the linkage frame 671 is fixedly connected with an overhanging mechanism 675, and the bottom of the inner cavity of the linkage frame 671 is located at Both sides of the overhanging mechanism 675 are fixedly connected with guide plates 673, and the middle part of the outer walls of both sides of the linkage frame 671 is fixedly connected with an overlapping plate 672. The bottom of the overlapping plate 672 runs through the linkage frame 671 and extends to the inside of the linkage frame 671. The bottom of 671 is fixedly connected with fixed teeth 674 .

[0040] Wherein, the extension mechanism 675 includes an extension rod d1, the bottom of the inner wall on both sides of the extension rod d1 is fixedly connected with a support block d2, the top of the inn...

Embodiment 3

[0043] see Figure 1-7 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the auxiliary mechanism d6 includes a force-bearing block d61, the two sides of the bottom of the force-bearing block d61 are fixedly connected with the limit block d62, and the limit block d62 The top is fixedly connected with the auxiliary plate d63, the middle part of the side of the auxiliary plate d63 away from the limit block d62 is fixedly connected with the contact block d64, the two sides of the top of the auxiliary plate d63 are fixedly connected with the force block d61, and the bottom of the inner cavity of the force block d61 Set with friction ball d65.

[0044] Wherein, the contact block d64 includes a friction increasing block t1, a reset block t2 is arranged at the bottom of the inner cavity of the friction increasing block t1, and the bottom of the friction increasing block t1 is fixedly connected with a dismounting head t3 on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com