Hanging device, brake clamp unit adopting same and hanging connection method

A hanging device and brake caliper technology, applied in the field of rail transit, can solve the problems of inability to relieve fatigue, poor anti-fatigue performance of four-point hoisting, etc., and achieve the effects of overall weight reduction, good manufacturability, and reduction of internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

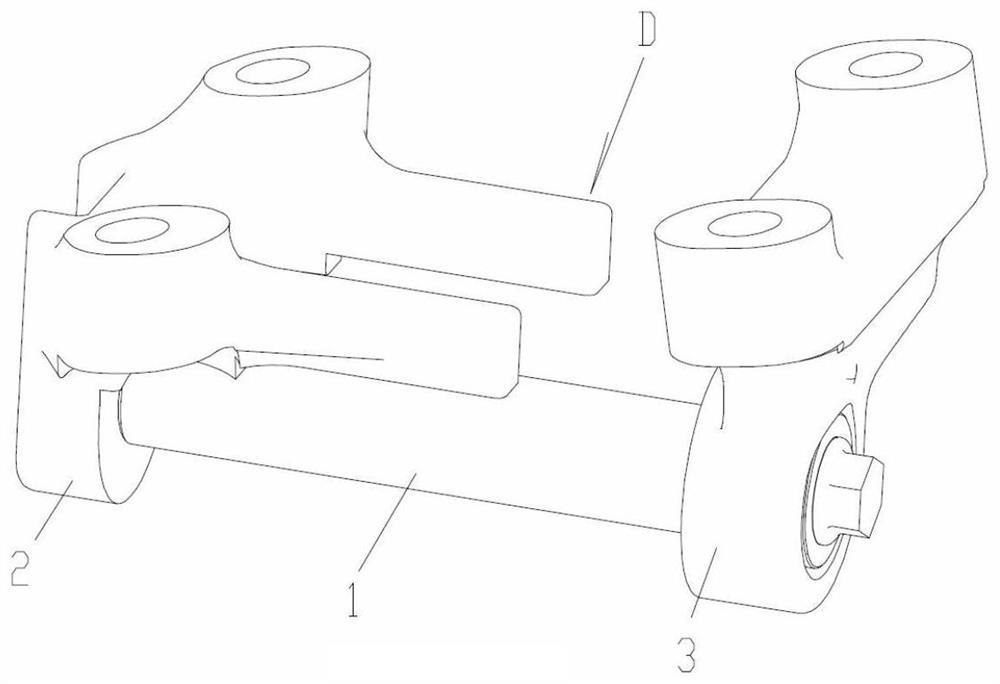

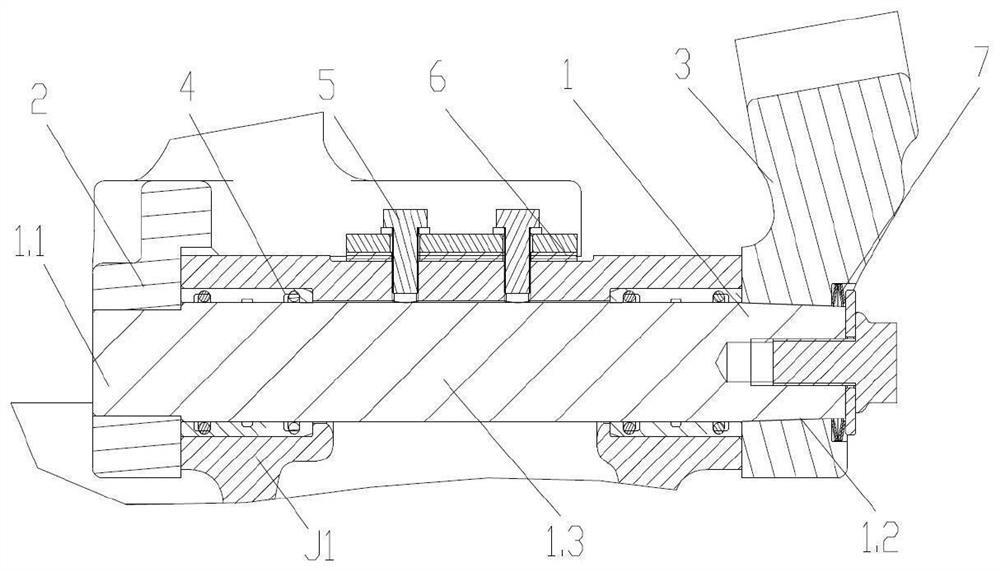

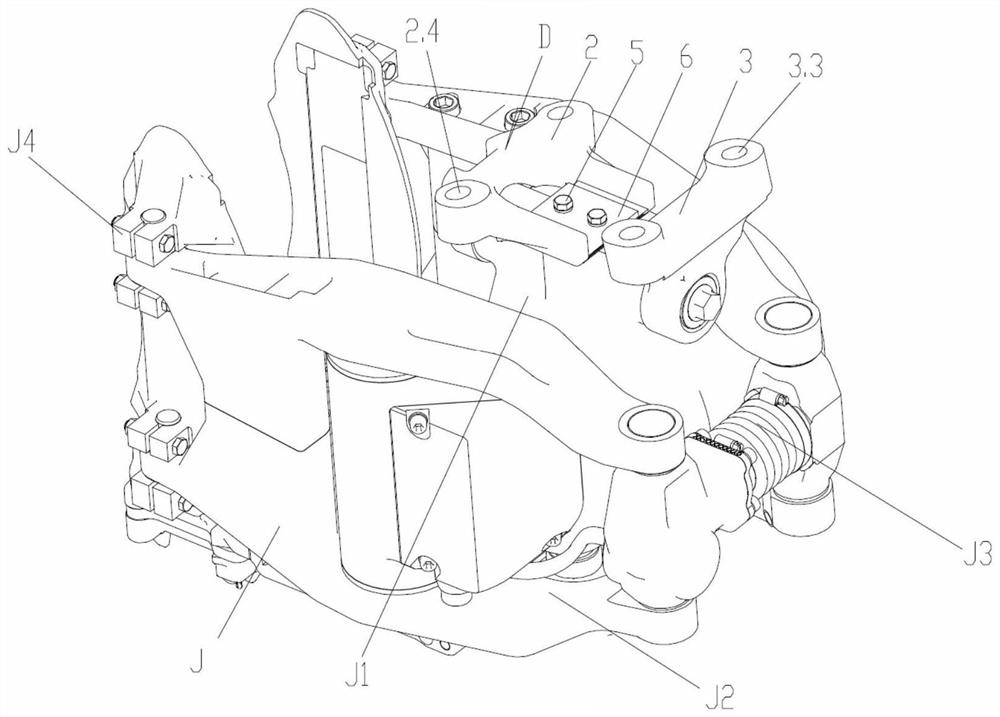

[0037] The hanging device D of this embodiment is as figure 1 with figure 2 As shown, it includes a front hanger 2 and a rear hanger 3 which are separated from each other, and a hanger pin 1 for connecting the main body J of the clamp during installation.

[0038] Front suspension 2 such as Figure 4 to Figure 7 As shown, there is a front main body 2.1 that is vertically T-shaped, and the bottom of the front main body 2.1 is shaped on a horizontal front piercing hole 2.2. The front end surface of the upper part of the front main body 2.1 is in the shape of a curved arc protruding forward, and the two ends are respectively formed with vertical front hanging holes 2.4. The rear parts of the two front hanging holes 2.4 respectively extend out the positioning rods 2.3 whose lower surfaces are formed with anti-yaw constraint planes 2.31. As shown in FIG. 2 and FIG. 3 , the anti-yaw constraint plane 2.31 is used to cooperate with the pressure plate 6 fixed on the top of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com