Preparation method of sea squirt nanocellulose-based heavy metal adsorbent

A technology of nanocellulose and true ascidian, which is applied in the directions of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., to achieve the effects of good degradability, strong physical cross-linking, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The embodiment of the present invention discloses a method for preparing an ascidian nanocellulose-based heavy metal adsorbent, which specifically includes the following steps:

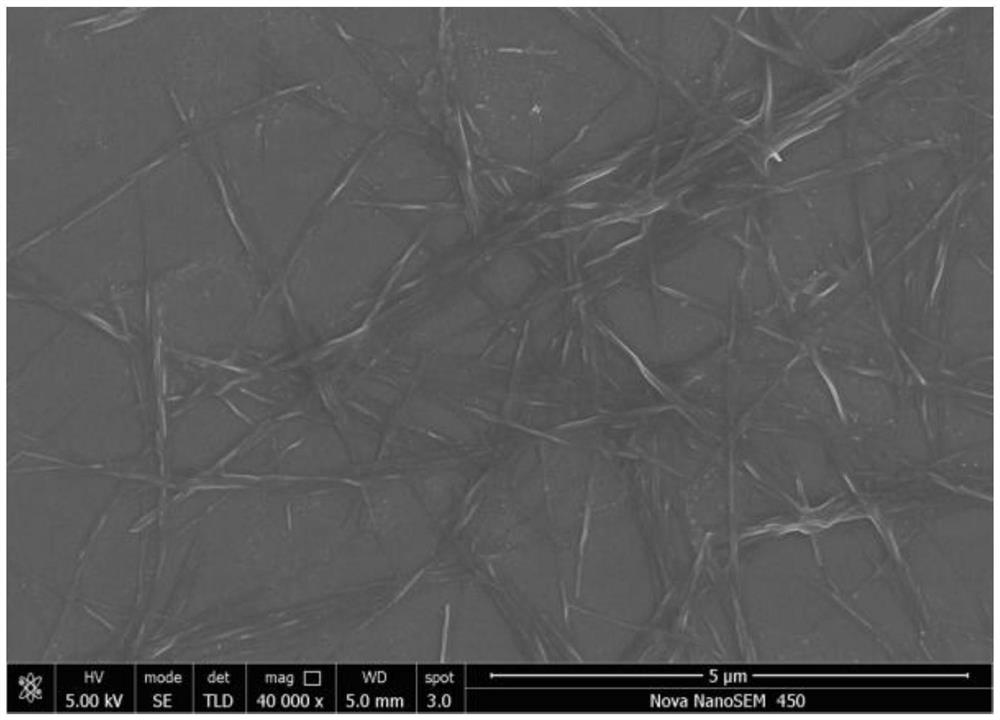

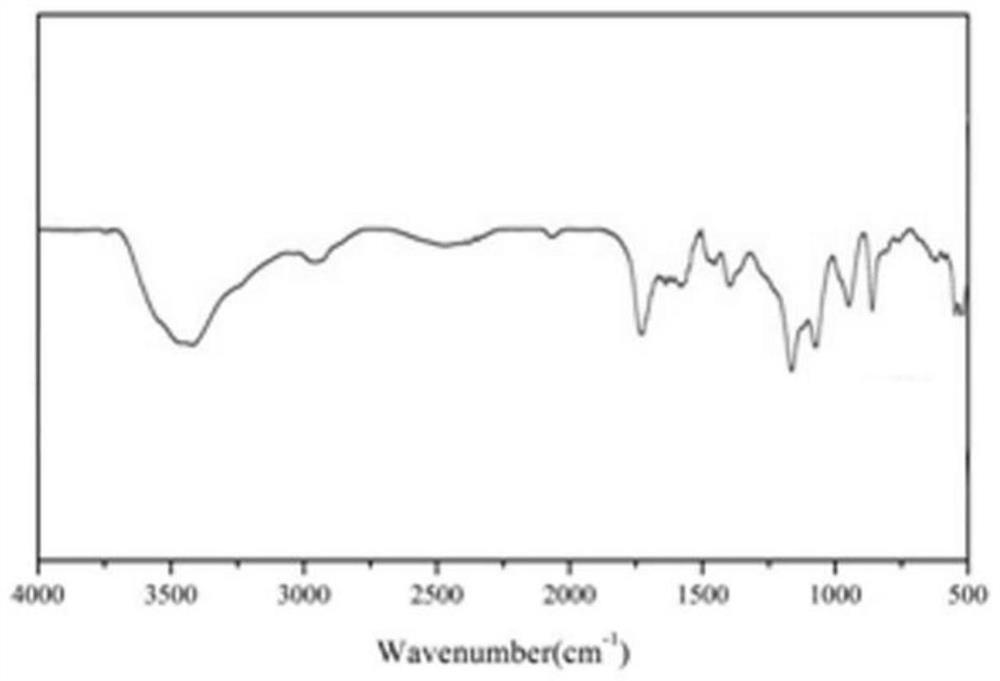

[0074] (1) Isolate tunicin from true sea squirt, then add sulfuric acid to hydrolyze it, let it stand still, then centrifuge to obtain the centrifugate, then dialyze it with deionized water to neutrality, and then freeze-dry to obtain white flocculent tunicin nano Whiskers;

[0075] Wherein, the mass concentration of sulfuric acid solution is 60wt%, and the mass volume ratio of tunicin and sulfuric acid solution is 400g / 400mL;

[0076] The temperature of hydrolysis is 60°C, the time is 3 hours, and the number of times is 3 times;

[0077] The standing time is 8 hours, and the temperature is 25°C;

[0078] Centrifugal speed 2000r / min, time 5min;

[0079] For dialysis, add it to a dialysis bag with a specification of MD44 (1000), then soak it in deionized water for dialysis, and change the dei...

Embodiment 1

[0097] Embodiment 1 of the present invention discloses a preparation method of a high-strength and high-efficiency E. ascidian nanocellulose-based heavy metal adsorbent, which specifically includes the following steps:

[0098] (1) Preparation of tunicin nanowhiskers

[0099] (a) Wash and dissect the fresh ascidian, cut off the root of the true ascidian, and remove the viscera; then place it in a beaker, add 5wt% NaOH solution, soak for 8 hours at room temperature, then pour off the NaOH solution, and repeat with deionized water Wash until neutral; then remove the inner membrane to separate the outer capsule from the inner membrane, so as to facilitate the subsequent alkali washing to remove lipids, and the outer capsule of the true ascidian can be obtained;

[0100] (b) Cut the outer coat of Ascidian ascidian into small pieces, add 5wt% NaOH solution and place it in a beaker, put the beaker in a water bath, stir with a stirring bar at 45°C for 8 hours; then repeat the above o...

Embodiment 2

[0111] Embodiment 2 of the present invention discloses a preparation method of a high-strength and high-efficiency E. ascidian nanocellulose-based heavy metal adsorbent. The steps and specific technical parameters are the same as in Embodiment 1. Only the methacrylic acid N, N -Dimethylaminoethyl ester and acrylic acid are replaced by 0:100 according to the mass ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com