Speed-adjustable asynchronous opposite-cutting type straw smashing device

A pulverizing device and straw pulverizing technology are applied in cutting equipment, agricultural machinery and implements, applications, etc., which can solve the problems that the pulverizing speed cannot be adjusted in real time, the pulverizing effect is not good, and the powder leakage rate is high, so as to improve the operation reliability and improve the Crushing effect, effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

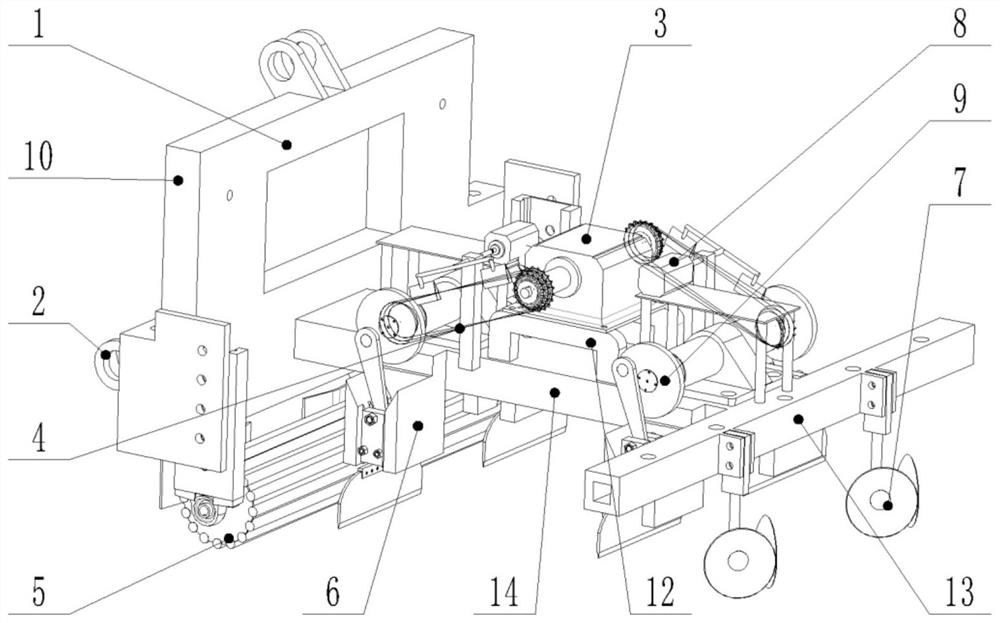

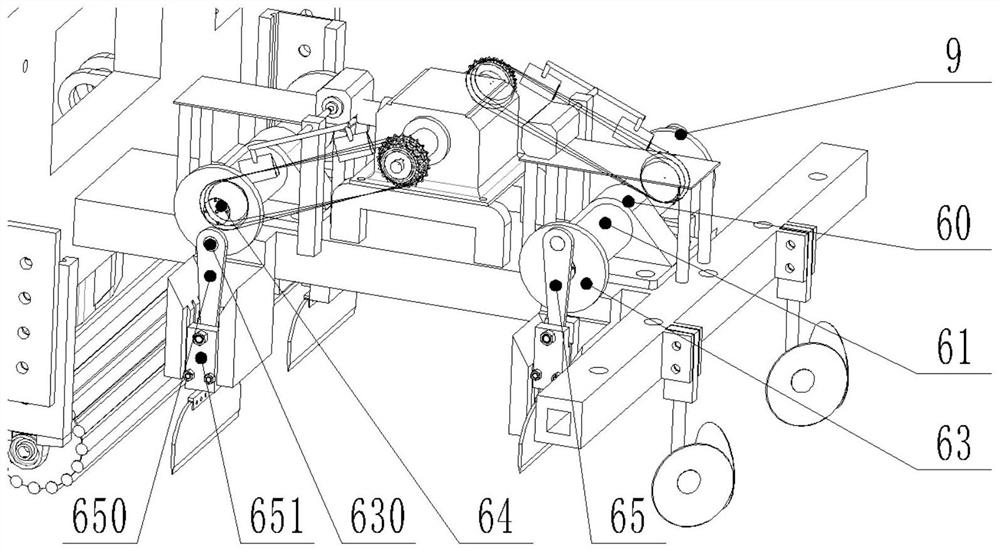

[0099] Such as Figure 1a and Figure 1b As shown, the direction V is the forward direction of the speed-adjustable asynchronous split-cut straw crushing device of the present invention.

[0100] Adjustable speed and asynchronous split-type straw crushing device, including frame assembly 1, three-point suspension device 2, gearbox 3, transmission assembly 4, comb rod suppression device 5, crushing device 6, stubble cleaning device 7, and speed change device 8 and crushing device assembly 9.

[0101] The frame assembly 1 includes a front frame 10 , a casing 11 , a gearbox support frame 12 , a rear frame 13 , and a middle support plate 14 . The middle support plate 14 is located between the front frame 10 and the rear frame 13 , and the two ends of the middle support plate 14 are affixed to the front frame 10 and the rear frame 13 . The transmission su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com